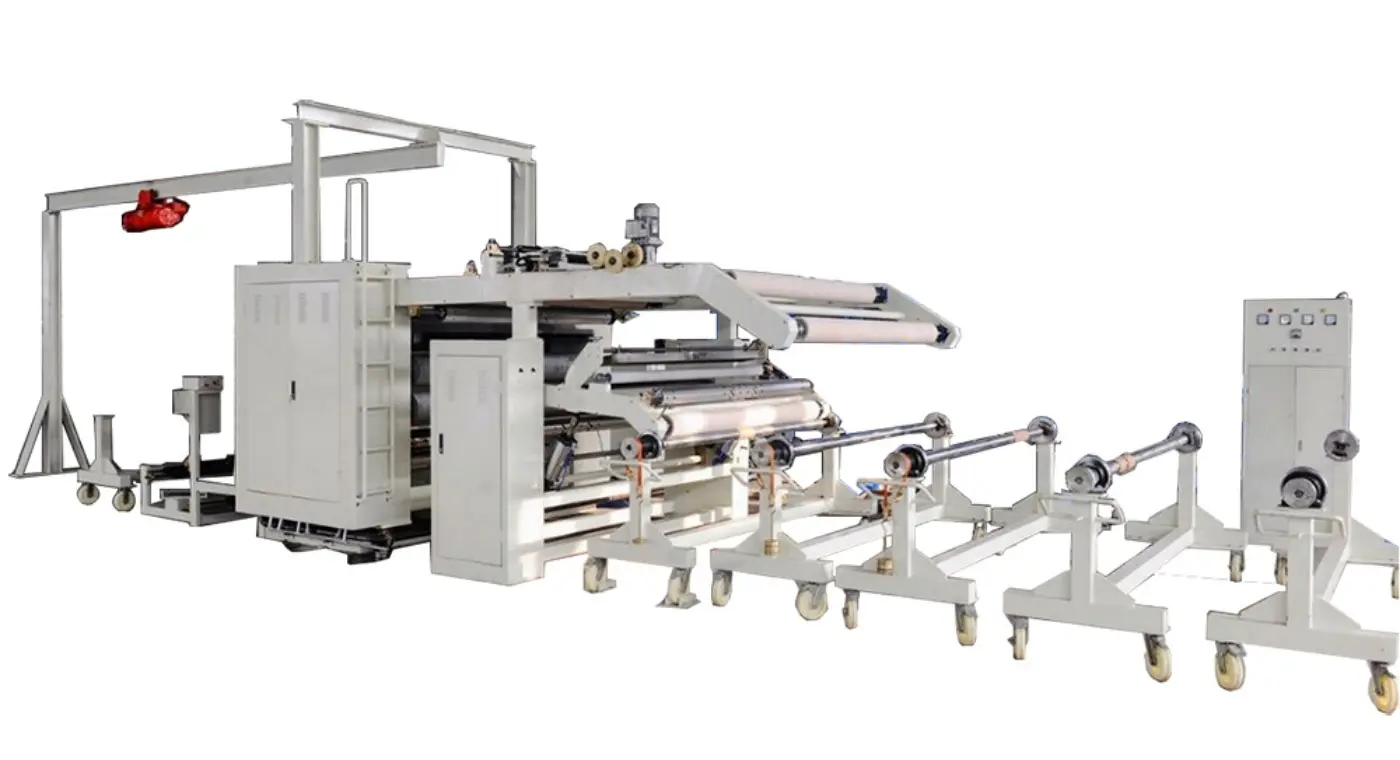

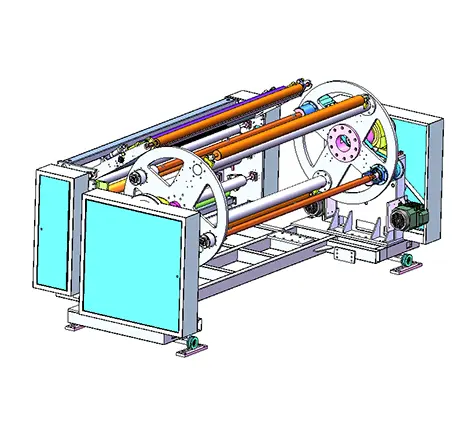

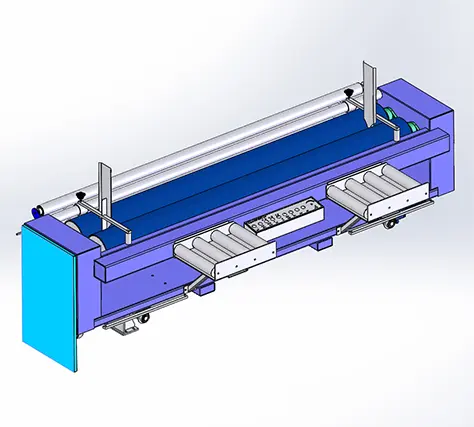

NONWOVEN FABRIC LAMINATING MACHINE description

Kuntai Group

Nonwoven fabric is a material similar to fabric, made of short fibers (short fibers) and long fibers (continuous long fibers), bonded together by chemical, mechanical, thermal, or solvent treatment. This term is used in the textile manufacturing industry to refer to fabrics that are neither woven nor knitted, such as felt.

Nonwoven fabrics have a wide range of applications, including agricultural planting, industrial processing, medical equipment, industrial machinery, environmental protection and purification industries.

Therefore, nonwoven fabric laminating machines are widely used in car interior industry, fruit guard industry, medical supplies industry, hometextile, etc.

Because nonwoven fabric is light and breathable, people laminate it with paper or film for fruit guard to protect fruit from extreme weather or harsh or long way transportation; Because the processing technology of non-woven fabric has created it with very dense small pores, which can filter pollutants in the air and impurities in water, so it is often used for air purification and water source purification. In the automotive industry, it is mainly used to produce filter materials for oil filters used in cars, and can also be used to make filter materials by nonwoven fabric laminating machine for air filters and gasoline filters; Because nonwoven fabrics have high flexibility, strength, and good breathability, people like to laminate it with TPU for medical protective clothing, bed sheets or mattress,etc.

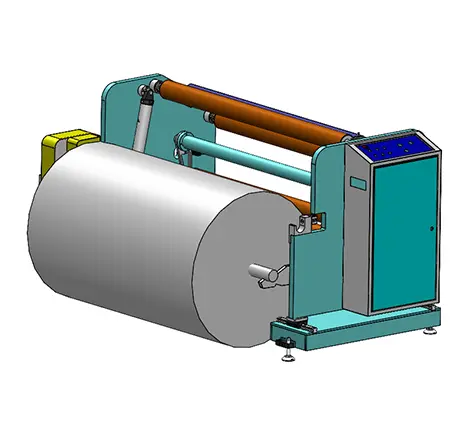

Along with the deveopment of nonwoven fabric, nonwoven fabric laminating machine also improves year after year in various aspects, for example, the feeding method of nonwoven fabric, the heating process for nonwoven fabric and so on.

Applicable adhesives

Kuntai Group

Hot melt PUR glue, Hot melt EVA glue, Water based glue, Solvent based glue, hot melt film, hot melt powder, etc.

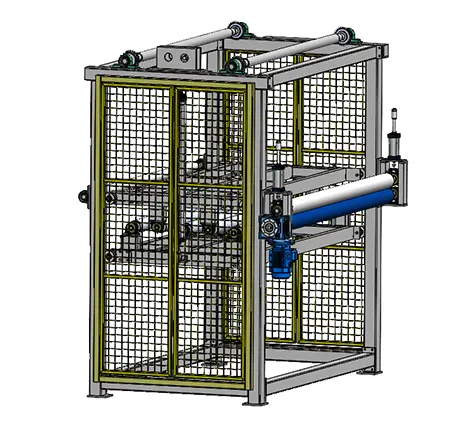

AccessoriesOption

01020304050607080910

NONWOVEN FABRIC LAMINATING Machine Features

Kuntai Group

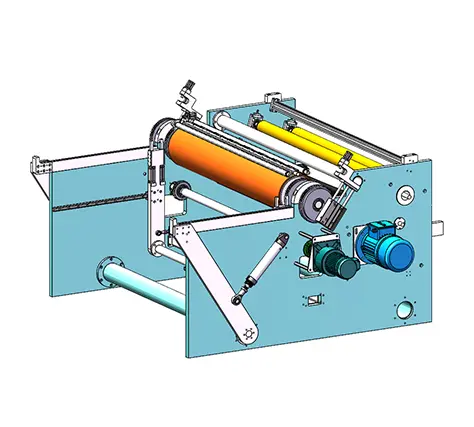

● Different industry applications require different types of glue usage in nonwoven fabric laminating machine and also different methods of applying glue onto nonwoven fabric.Kuntai nonwoven fabric laminating machine adopts the latest glue control methods.

● Precise and easy gluing gap and lamination gap adjustment is crucial in nonwoven fabric laminating machine because of the thin nonwoven capacity.

● PLC control can record and save the gap as per nonwoven fabric gsm and the other material thickness, speed, other data of nonwoven fabric lamination, so that the operators only need to read the previous preset data to recall the relavant operation for each product, realizing more intelligent operation.

● Siemens, Schneider, Yaskawa, Omron, Keyence and many other international famous brands parts can be used in Kuntai nonwoven fabric laminating machines.

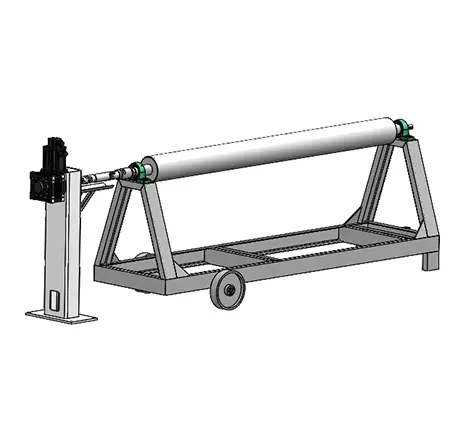

● If laminating nonwoven fabric with foam and artificial leather, Kuntai nonwoven fabric laminating machine will have platform for unwinding artificial leather and special foam products rewinder, reducing wrinkles or bubles in the final laminated product.

● Kuntai nonwoven fabric laminating machine provides uniform and stable heating process, which better preserves the nonwoven fabric's own features.

● High productivity, high efficiency, high flexibility and continuous durable operation can be realized in Kuntai nonwoven fabric laminating machines.

● Low maintenance cost, fewer operators and less running noise and more user friendly.

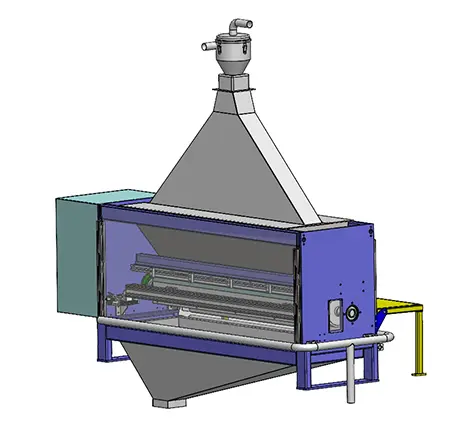

● Advanced powder scatter device makes sure the powder is scattered uniformly and well controlled onto nonwoven during the laminating process.

● Oil heater heating, electrical heating,electromagnetic induction heating and many other heating methods are available in nonwoven fabric laminating machines.

NONWOVEN FABRIC LAMINATING MACHINE Technical Parameters

Kuntai Group

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

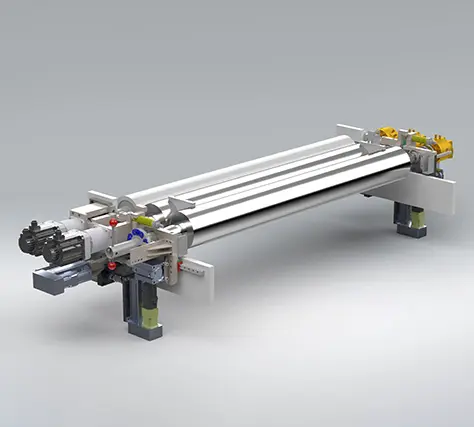

| Gap Adjustment | Servo Motor Control or Mechanical Control available for choice |

| Heating Method | Oil Heating, Natural Gas Heating, Electromagnetic Induction Heating, Electrical Heating Available for Customization |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 45-80kw, Customizable |

| Voltage | 220v, 380v, 415v, 440v, as per user's factory nearby power supply |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Glue applying method c. Heating method d. Fixed length online cutting |

NONWOVEN FABRIC LAMINATING MACHINE Application

Kuntai Group

Nonwoven fabric laminating machine is widely used in various industries, such as auto interiors, home textiles and decoration, advanced textiles, footwear, medicial protective clothing, packaging and many other industries. Nonwoven fabric laminating machine can laminate below materials:

✓ TPU film + nonwoven fabric

✓ Paper + Nonwoven Fabric

✓ Carpet Fabric + Nonwoven Fabric

✓ Nonwoven Fabric + Nonwoven Fabric

0102030405060708

Packaging And Shipping

Kuntai Group

Nonwoven Fabric Laminating Machine Inner Package: Protective Film, etc .

Nonwoven Fabirc Laminating Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88