2026-01-07

What is the New Application Form for UHMWPE Fibers?

The structure of the fabric is crucial for leveraging the performance advantages of ultra-high molecular weight polyethylene (UHMWPE) fibers. The woven structure can fully utilize the high-strength advantages of UHMWPE fibers, such as the plain weave fabric made of 800D high-strength polyethylene yarn, which has the characteristics of anti cutting, wear resistance, corrosion resistance, UV resistance, etc., and is widely used in sports clothing, special uniforms, tents, luggage and other fields. Knitted structures can provide better stretchability and comfort for outdoor clothing. The non-woven technology provides a new application form for UHMWPE fibers.

UD non-woven fabric (unidirectional fabric) made of UHMWPE fiber achieves extremely high defense protection and stab proof performance by impregnating the fibers into resin and laminating them with 90 degree UD sheets in the vertical direction, which can be used for high-end protective clothing.

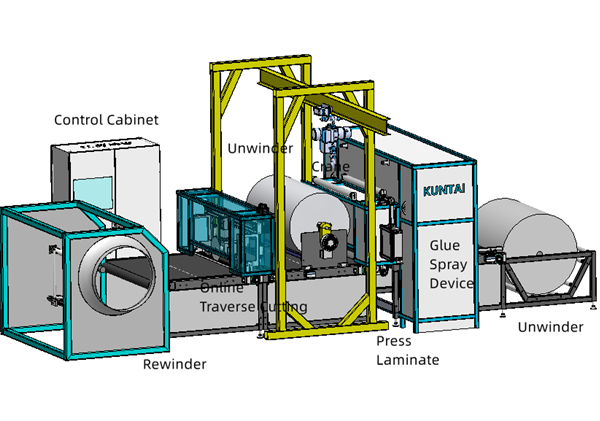

UD fabric prepreg machine spreads fibres and impregnates them into resin and then dry with drying roller and then rewind into UD fabric rolls. After getting unidirectinal UD fabric, people cut some into UD fabric sheets and then laminate 0 degree and 90 degree UD fabric together by thermal heating pressing either done by 2UD orthogonal lamination machine or multiple layers UD fabrics Crossply Machine. The whole process is non-woven technology, maintaining the best performance of fibers. This new technology is also suitable for aramid fibers.

UD fabric edge Cutting Machine will trim the fabric edges and UD fabric inspection machine will inspect the fabric before selling.

The final fabric produced by this new non-woven technology can be made into vest, helmet and plates for defense industry because of their high defense features and stab proof characteristics.

If you are looking for a whole nonwoven application production line for UD fabric (UD fabric prepreg machine, UD sheet cutting machine, UD crossply machine, UD orthogonal lamination machine), welcome to visit Kuntai for details discussion. We will listen to your application requirements and offer you the most suitable and applicable and reliable and durable solution and demonstrate to you the machines details.

UD fabric edge Cutting Machine will trim the fabric edges and UD fabric inspection machine will inspect the fabric before selling.

The final fabric produced by this new non-woven technology can be made into vest, helmet and plates for defense industry because of their high defense features and stab proof characteristics.

If you are looking for a whole nonwoven application production line for UD fabric (UD fabric prepreg machine, UD sheet cutting machine, UD crossply machine, UD orthogonal lamination machine), welcome to visit Kuntai for details discussion. We will listen to your application requirements and offer you the most suitable and applicable and reliable and durable solution and demonstrate to you the machines details.

Wechat: ANNIELV88

Wechat: ANNIELV88