In an increasingly competitive print industry, the quest for print longevity has never been more crucial. The durability of printed materials can significantly impact customer satisfaction and brand perception, as evidenced by recent industry reports suggesting that 70% of businesses are now prioritizing print durability to enhance their products' lifespan.

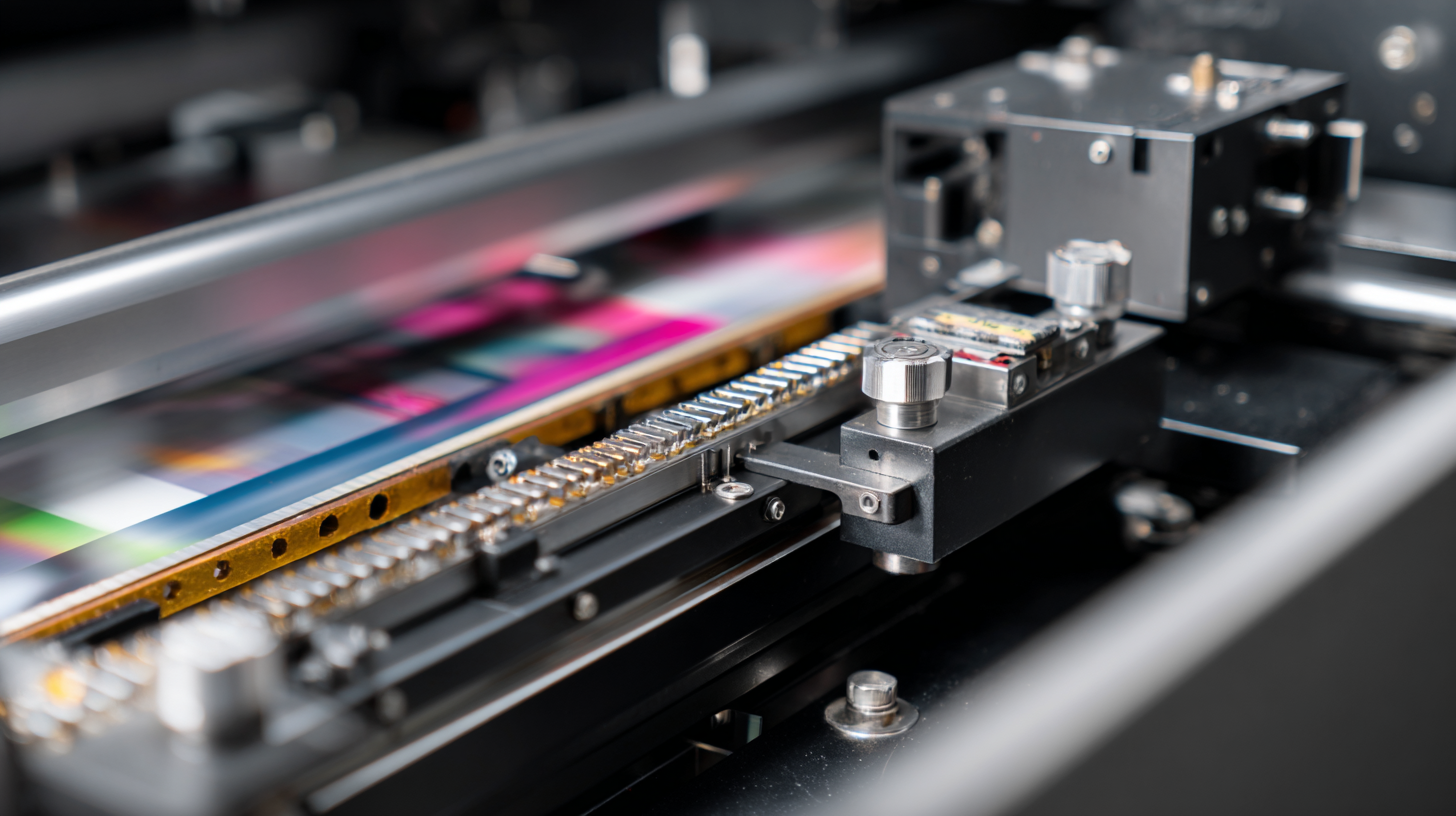

Enter the Ud Laminating Machine, a revolutionary tool designed to address these demands effectively. Utilizing advanced laminating technology, these machines ensure that prints are protected against wear, tear, and environmental factors, extending their usable life. Moreover, a study by Smithers Pira estimates that the global market for laminating films will reach $20 billion by 2025, underlining the importance of investing in high-quality laminating solutions like the Ud Laminating Machine.

By exploring the operational advantages and capabilities of this technology, businesses can unlock the true power of durability and elevate the quality of their print offerings.

In modern industries, the durability of printed materials has become increasingly crucial. As businesses strive to create lasting impressions, enhancing print longevity through advanced technologies is paramount. The rising demand for durable prints is evident across various sectors, from packaging and advertising to textiles and 3D printing. This interplay of durability and innovation paves the way for companies to maintain their competitive edge while addressing consumer expectations for quality and longevity.

The adoption of sophisticated laminating machines is a key strategy in achieving superior print durability. These machines not only protect the printed surfaces from wear and tear but also ensure that colors remain vibrant over time. As industries shift towards more sustainable practices, the efficiency and reliability offered by high-quality laminators will be instrumental in reducing waste and enhancing the overall value of printed products. This focus on durability is not just a trend; it is a necessary evolution in a landscape where first impressions are often the last.

Laminating machines play a crucial role in enhancing the longevity of printed materials, ensuring that they withstand the wear and tear of daily use. According to a study by InfoTrends, nearly 80% of print providers believe that finishing processes like lamination can significantly extend the lifespan of printed products. By applying a protective layer, Ud laminating machines safeguard prints from moisture, UV rays, and physical abrasion, which are primary enemies of print integrity. This durability is particularly essential in environments where materials are frequently handled or exposed to various elements, such as educational institutions and outdoor advertising.

Tips for achieving optimal results with Ud laminating machines include selecting the appropriate film thickness based on the application—thicker films generally provide better protection against abrasion and moisture. Furthermore, maintaining the machine at recommended operating temperatures can prevent bubbling and ensure smooth finishes. Regular maintenance and cleaning of the laminating rollers also contribute to consistent adhesion quality, preventing unwanted defects in the output.

Incorporating Ud laminating machines into your finishing process not only enhances the durability of your prints but also improves their overall aesthetic appeal. A report by Smithers Pira states that the demand for printed materials with enhanced durability is increasing as brands aim to produce high-quality, long-lasting products that resonate with consumers. By leveraging the capabilities of Ud laminating machines, businesses can trust that their printed materials will stand the test of time while maintaining their visual impact.

| Parameter | Description | Impact on Print Longevity |

|---|---|---|

| Lamination Thickness | The thickness of the lamination film used on prints. | Thicker films generally provide better protection against wear and tear. |

| Finish Type | Options like gloss, matte, or textured finishes. | Different finishes can enhance durability and visual appeal. |

| Temperature Control | Ability to adjust temperature during the laminating process. | Proper temperature ensures optimal adhesion and longevity. |

| Speed Settings | Control over the speed of lamination process. | Adjusting speed can prevent bubbling and improve finish quality. |

| Ease of Use | User-friendly controls and interface of the laminating machine. | A more intuitive operation reduces errors and improves output quality. |

| Energy Efficiency | Energy consumption of the machine during operation. | Lower energy costs contribute to sustainability in printing. |

Laminating machines have become an essential tool for enhancing the durability of printed materials. Among the various models available, UD laminating machines stand out due to their advanced features that significantly boost print longevity. These machines utilize high-quality laminating films that not only protect against moisture and dirt but also enhance the color vibrancy of printed documents. The heat and pressure applied during the laminating process ensure a strong bond, preventing wear and tear over time.

When selecting a UD laminating machine, consider features such as adjustable temperature settings and speed control. These options allow users to customize their laminating process based on the specific needs of their documents, whether they are delicate prints or robust materials. Additionally, many models come equipped with multiple roller systems, ensuring an even application across the laminate for superior results.

Tips: To maximize the durability of your laminated documents, always ensure that the materials are completely dry before laminating. This helps prevent bubbling or separation in the laminate. Furthermore, regularly clean the laminating machine to maintain its functionality and ensure optimal adhesion for each use.

When it comes to enhancing print longevity, the choice of laminating machine can make a significant difference. Ud laminating machines stand out in a comparative analysis against traditional laminating solutions, primarily due to their advanced technology and superior durability. According to a recent industry report by Smithers Pira, the demand for high-quality laminating solutions has surged, with expectations to grow by 4.3% annually through 2025. Ud laminating machines leverage cutting-edge features that not only provide a thicker lamination but also utilize UV-curable materials, offering up to 50% more resistance to scratches and fading compared to conventional methods.

One major advantage of Ud laminating machines is their energy efficiency. Traditional machines often consume more energy for less output, but Ud laminating solutions boast a 30% reduction in energy usage while producing better results. As the industry shifts toward sustainability, this aspect sets Ud apart from its competitors.

Tips for maximizing the longevity of your prints include selecting the right thickness for lamination—ranging from 3 to 10 mils depending on the application—and always ensuring that the lamination process is performed under optimal temperature and pressure settings. Employing Ud laminating machines can streamline this process while guaranteeing top-notch durability for your printed materials.

Ud laminating machines play a crucial role in enhancing print longevity across various industries, ensuring that printed materials not only look good but also stand the test of time. In sectors such as education, marketing, and packaging, the application of durable lamination contributes significantly to the aesthetics and functionality of materials. Educational institutions, for instance, utilize laminated materials for posters, charts, and handouts, preserving them from wear and tear while also providing a professional finish that captures attention.

Ud laminating machines play a crucial role in enhancing print longevity across various industries, ensuring that printed materials not only look good but also stand the test of time. In sectors such as education, marketing, and packaging, the application of durable lamination contributes significantly to the aesthetics and functionality of materials. Educational institutions, for instance, utilize laminated materials for posters, charts, and handouts, preserving them from wear and tear while also providing a professional finish that captures attention.

Moreover, businesses involved in branding and marketing are increasingly adopting Ud laminating machines to create visually appealing promotional materials. The ability to laminate brochures, business cards, and product packaging helps in not only maintaining the quality of these items but also enhancing their appeal. The resistance to fading, moisture, and physical damage ensures that these materials convey a consistent message over time. As companies continue to seek innovative solutions for maintaining the quality of their printed materials, the real-world applications of Ud laminating machines serve as a testament to their value in achieving lasting impressions.