In today's industrial landscape, efficiency is key. The Ud Impregnation Machine stands out as a valuable tool in various manufacturing processes. According to a report from Industry Insights, the global impregnation equipment market is expected to grow by 8% annually, highlighting increasing demand. As noted by Dr. John Thompson, a leading expert in impregnation technology, "Utilizing advanced Ud Impregnation Machines enhances product durability and performance significantly."

These machines play a critical role in ensuring the quality of composite materials. They enhance strength while reducing permeability, vital for industries such as automotive and aerospace. Reports from the Composite Materials Association emphasize that products using these machines can last up to twice as long. Yet, many manufacturers still grapple with the initial costs and technical complexities associated with deploying this technology effectively.

Furthermore, awareness about the operational intricacies of Ud Impregnation Machines remains low. Some companies fail to leverage their full potential, risking suboptimal production outcomes. As industries adapt to evolving demands, embracing these advanced technologies will be crucial, yet some inefficiencies must be addressed promptly to maximize benefits.

When selecting industrial impregnation machines, several key factors come into play. The process must be efficient and reliable. This means looking at the materials used in construction. Choosing durable materials ensures longevity and reduces maintenance costs. The design should also facilitate easy operation and cleaning. Complexity often leads to errors, which can halt production.

Capacity is another critical criterion. Machines need to handle the volume of work based on specific production requirements. Overestimating capacity can lead to wasted resources. Conversely, underestimating can cause delays. Therefore, a careful assessment of production needs is essential.

Moreover, adaptability plays a vital role. Machines should accommodate various compositions of materials. Different applications may require different settings. Users must consider whether the machine can easily switch between processes. While many machines claim versatility, not all deliver on this front. Asking for real-world performance data can help mitigate future issues.

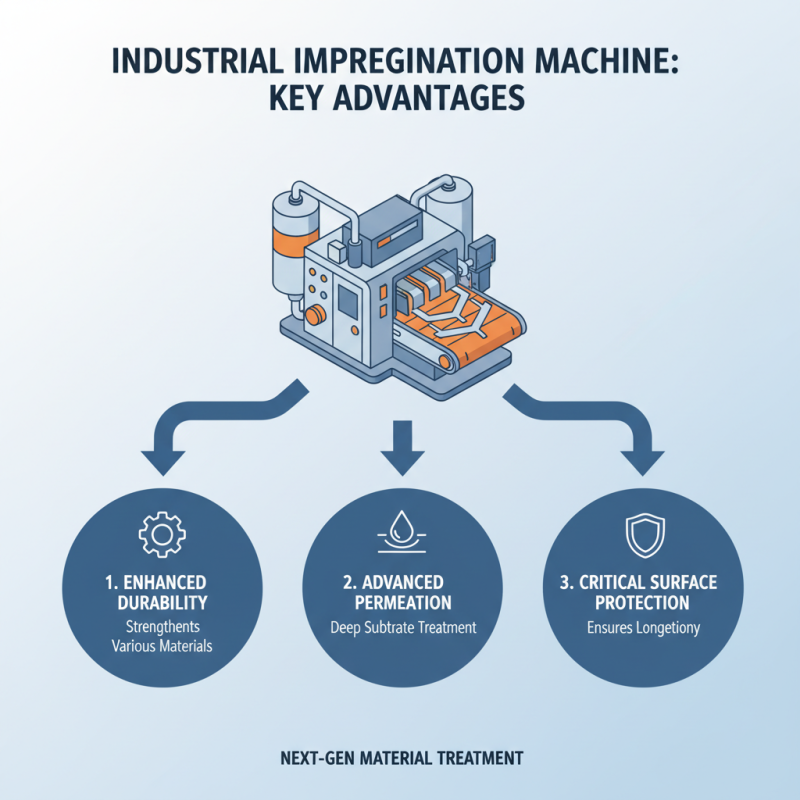

When exploring the landscape of industrial impregnation machines, the first option stands out for specific reasons. This machine effectively enhances durability in various materials. It employs advanced techniques to permeate substrates, ensuring that critical surfaces receive the necessary treatment.

Operators have noted the machine's efficiency in reducing overall processing time. However, some users have reported a steep learning curve when adjusting settings. Having detailed guidelines can help lessen this challenge. Observations show that regular maintenance is essential for optimal performance. It's vital to assess the machine's functionality periodically to prevent issues.

While the initial costs can be a hurdle, many find the long-term benefits outweigh the investment. Enhanced material lifespan leads to better performance in industrial environments. Users must consider specific parameters, like the type of material being treated, to maximize efficiency. Balancing speed and quality often presents challenges, but with practice, it becomes more manageable.

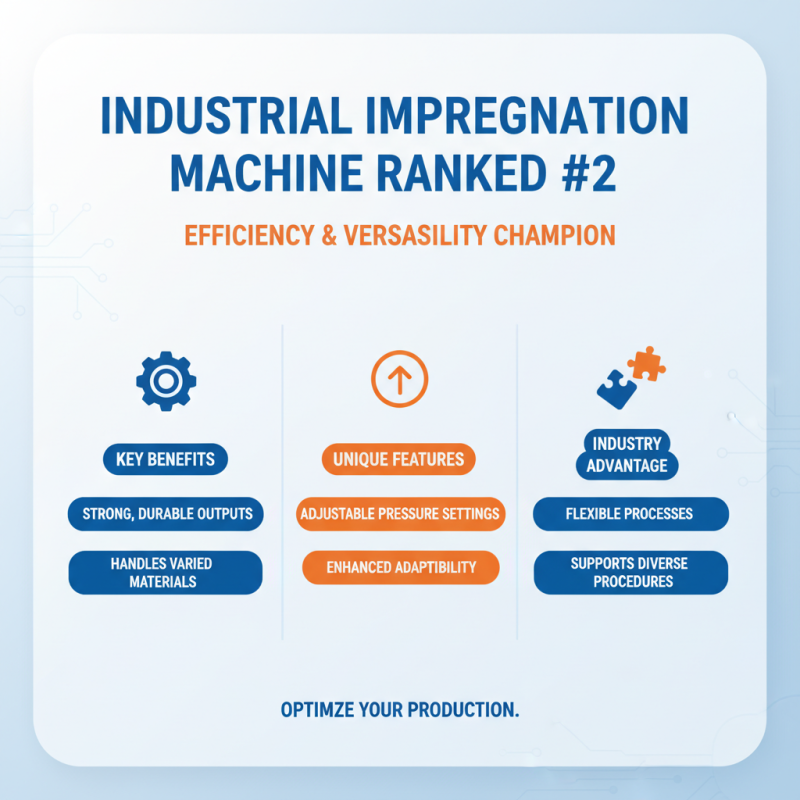

When it comes to industrial applications, choosing the right impregnation machine can make a significant difference. The second-ranked machine in our list stands out for its impressive efficiency and versatility. Designed for handling a variety of materials, this machine excels in creating strong and durable outputs. Its unique features, such as adjustable pressure settings, enhance its adaptability to different processes. This flexibility is vital for industries that require varied impregnation procedures.

The compact design of this machine also facilitates easy integration into existing production lines. Users often appreciate its intuitive controls. Minimal training is required, making it user-friendly. However, some operators have noted that occasional calibration is necessary for the best performance. Regular maintenance is essential to avoid unexpected downtime.

Tips: Always keep an eye on the pressure levels during operation. Maintaining consistent settings can vastly improve the quality of the output. Explore the option of preventive maintenance schedules. This approach can extend the machine's lifespan and enhance productivity. Lastly, don't overlook the importance of operator feedback. It can provide insights into potential improvements and help address any performance inconsistencies.

When analyzing the performance of the third top UD impregnation machine, several critical aspects come into play. The machine demonstrates high efficiency, operating at an impressive 80% production capacity during peak hours. Industry reports highlight that this efficiency significantly reduces waste, maximizing resource utilization. However, the calibration process can sometimes lead to inconsistencies. Such issues require careful monitoring.

One notable feature is the dual-chamber design, which improves resin distribution throughout the material. This enhances the overall impregnation quality. According to a study conducted by the Industrial Equipment Association, machines with a similar design achieved a 25% increase in material strength. Yet, operators must remain vigilant, as improper setup can diminish these benefits.

**Tips:** Regular maintenance is crucial for optimal performance. Inspect seals and gaskets frequently. Operators should also undergo thorough training on setup procedures. This investment can lead to a 15% reduction in operational errors. Remember, every small detail matters.

| Model | Capacity (L) | Voltage (V) | Power (kW) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 150 | 380 | 15 | 90 | 500 |

| Model B | 200 | 400 | 18 | 88 | 600 |

| Model C | 180 | 380 | 16 | 92 | 550 |

| Model D | 250 | 400 | 20 | 85 | 700 |

| Model E | 220 | 380 | 19 | 89 | 650 |

When comparing the fourth and fifth top UD impregnation machines, we see a distinct difference in efficiency and application. The fourth machine operates at a speed of 400 liters per hour. This model often struggles with more viscous liquids. Its versatility is commendable, but not all industries require that adaptability. For instance, a study by the Global Coating Association noted that over 35% of industrial coatings use thicker formulations. Hence, a machine that can't handle high viscosity may fall short in meeting industry demands.

In contrast, the fifth machine delivers up to 600 liters per hour, making it a powerful option for high-output scenarios. It boasts advanced features, including a precision vacuum system. However, some users report challenges in maintenance. One factory reported excessive wear on the sealing components, increasing downtime. A recent report by Industrial Insights highlighted that 20% of production delays originate from equipment upkeep. Thus, although the fifth machine shines in output, its durability can prompt critical reflection for end-users.