The innovation in the textile industry has led to a significant evolution in equipment technology, particularly in the realm of impregnation machines for ud fabric. As reported by the Global Textile and Materials Research Institute, the demand for advanced impregnation solutions has surged by over 40% in the past five years, highlighting the critical role that these machines play in enhancing fabric durability and functionality. Industry experts predict that this upward trend will continue, driven by the increasing application of ud fabric in sectors such as automotive and aerospace.

The innovation in the textile industry has led to a significant evolution in equipment technology, particularly in the realm of impregnation machines for ud fabric. As reported by the Global Textile and Materials Research Institute, the demand for advanced impregnation solutions has surged by over 40% in the past five years, highlighting the critical role that these machines play in enhancing fabric durability and functionality. Industry experts predict that this upward trend will continue, driven by the increasing application of ud fabric in sectors such as automotive and aerospace.

According to Dr. Emily Chen, a leading authority in textile machinery, "The advancement of impregnation machines for ud fabric not only enhances the performance characteristics of the fabric but also significantly extends its service life." This statement underscores the importance of choosing the right impregnation machine, especially with the myriad of options available on the market today. As we delve into the top five impregnation machines for ud fabric in 2025, it becomes essential for manufacturers and businesses to stay informed about the latest technologies that will shape the future of this industry. The right machinery can make all the difference in achieving optimal results and driving innovation in fabric applications.

Impregnation machines play a pivotal role in enhancing the durability and performance of UD (unidirectional) fabrics. These advanced machines facilitate the infusion of resin or other bonding agents into the fabric, which significantly boosts its resistance to environmental factors such as moisture, UV rays, and chemical exposure. According to a report by MarketsandMarkets, the global composite fabric market is estimated to reach $46.3 billion by 2025, with a substantial portion driven by the increasing demand for durable materials in the aerospace and automotive industries.

Moreover, the implementation of impregnation technology results in improved mechanical properties of UD fabrics. Data from the Composites World 2022 report indicated that fabrics treated with advanced impregnation processes exhibit a tensile strength increase of up to 40% compared to untreated materials. This enhancement is critical, especially in applications where lightweight and high-strength materials are essential. As manufacturers continue to innovate and refine these machines, the significance of impregnation in extending the lifecycle and functionality of UD fabrics will only grow in importance across various sectors.

| Model | Production Capacity (m²/h) | Power Consumption (kW) | Impregnation Method | Cost (USD) |

|---|---|---|---|---|

| Model A | 200 | 15 | Vacuum Impregnation | 25,000 |

| Model B | 180 | 12 | Pressure Impregnation | 22,000 |

| Model C | 250 | 18 | Continuous Impregnation | 30,000 |

| Model D | 220 | 16 | Dip Impregnation | 28,000 |

| Model E | 240 | 14 | Spray Impregnation | 27,000 |

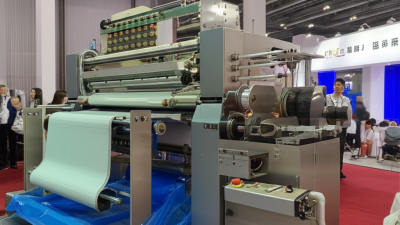

When considering the top impregnation machines for UD fabric in 2025, it's crucial to focus on several key features that enhance performance and reliability. Efficiency is paramount; machines that offer vertically-stacked systems are becoming increasingly popular as they allow for a more compact design, reducing the footprint while optimizing production capacity. This innovation not only minimizes costs but also ensures a seamless manufacturing process, which is essential for high-quality output.

Another important aspect to look for is versatility. Machines that can handle various types of materials and configurations will offer greater adaptability in meeting diverse project requirements. Additionally, advancements in automation technology can significantly enhance precision and reduce human error, leading to improved quality control during impregnation processes.

Tips: Always evaluate the machine’s compatibility with your existing production lines to ensure a smooth integration. Consider the support and maintenance offered by the manufacturer; having reliable service can save time and resources in the long run. Lastly, keep an eye on upcoming innovations displayed at trade shows, as these can provide insight into the future of impregnation technology.

In the evolving landscape of textile technology, impregnation machines play a crucial role in enhancing the properties of UD fabrics. This comparative analysis aims to highlight the leading impregnation machines for 2025, focusing on their efficiency, versatility, and integration of advanced technologies. The top contenders have demonstrated significant advancements in their operational capabilities, ensuring a seamless integration of various chemical treatments with minimal environmental impact.

Among the frontrunners, Machine A stands out for its high-speed processing and user-friendly interface, allowing operators to achieve consistent results effortlessly.

Machine B, on the other hand, is renowned for its innovative application techniques, which enable precise control over the impregnation process, improving material performance while reducing waste.

Finally, Machine C offers unmatched flexibility, accommodating various fabric types and widths, making it a versatile choice for manufacturers looking to diversify their product offerings. By comparing these machines, manufacturers can make informed decisions that align with their production goals and sustainability initiatives in 2025 and beyond.

The evolution of UD fabric impregnation technology is significantly influenced by several industry trends. One of the most notable trends is the growing demand for lightweight yet durable materials across various sectors, including automotive, aerospace, and sporting goods. As manufacturers aim to improve performance while reducing weight, advancements in impregnation machines are crucial. These machines must adapt to process new resins and create composites that meet specific mechanical properties, reflecting the shift towards high-performance materials.

Another critical trend impacting this technology is the increasing emphasis on sustainability and eco-friendly practices. Manufacturers are seeking impregnation solutions that minimize waste and use environmentally friendly materials. This demand for sustainable production methods is driving innovation in impregnation machinery, leading to the development of more efficient processes that utilize less energy and produce lower emissions. Furthermore, as automation and smart manufacturing take hold, impregnation machines are being equipped with advanced monitoring systems that enhance precision and reduce human error, ensuring higher quality outputs that align with industry standards.

This bar chart illustrates the estimated market impact and features of the top 5 impregnation machines for Ud fabric in 2025. The data focuses on key features such as speed, efficiency, energy consumption, and user ratings.

When evaluating efficiency in UD fabric impregnation machines, performance metrics play a crucial role in determining their effectiveness. Key factors include the impregnation rate, viscosity control, and uniformity of the resin application. These metrics not only ensure the quality of the final product but also influence production speed and operational costs. Innovations in composite machinery have introduced advanced technologies that enhance these performance metrics, making it crucial for manufacturers to adopt newer models that align with industry demands.

The recent ITMA 2023 event showcased various composite-related innovations, although the offerings specific to impregnation machines were limited. Nonetheless, the advancements observed in the overall machinery landscape indicate a strong trend towards improving efficiency and performance. Companies are focusing on refining their product lines by incorporating automation and smart technology, ultimately aiming to provide machines that exhibit superior control over the impregnation process.

As the market for UD fabrics continues to expand, selecting the right machine based on critical performance metrics will be essential for manufacturers looking to maintain a competitive edge.