In the ever-evolving landscape of modern manufacturing, precision cutting has become paramount, and the Swing Arm Cutting Machine is at the forefront of this revolution. Experts in the industry, like Dr. Emily Carter, a renowned mechanical engineer and specialist in cutting technologies, emphasize the significance of these machines in enhancing operational efficiency. Dr. Carter once stated, “The Swing Arm Cutting Machine represents a leap forward in accuracy and speed, enabling manufacturers to achieve unprecedented levels of productivity.” Such statements reflect the transformative impact these machines have on production lines across various sectors.

The Swing Arm Cutting Machine's innovative design not only optimizes space and workflow but also allows for intricate cutting tasks that were previously difficult to execute with conventional machinery. With advancements in technology, these machines offer precision that meets the rigorous demands of today's manufacturing environment. As industries strive to balance quality with cost-effectiveness, the Swing Arm Cutting Machine stands out as a critical investment for businesses aiming to stay competitive in a global market.

As we explore the science behind the Swing Arm Cutting Machine, we will delve into its operational mechanics, the materials it can effectively handle, and the role it plays in enhancing precision across manufacturing processes. This examination will shed light on why embracing such cutting-edge technology is essential for any manufacturer looking to revolutionize their operations and set new standards in precision engineering.

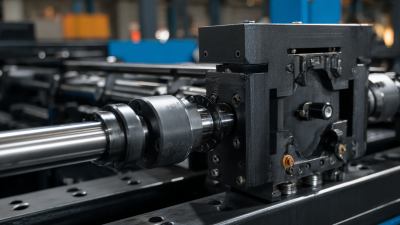

Swing arm cutting machines have emerged as a revolutionary tool in modern manufacturing, thanks to their innovative mechanisms that optimize cutting precision and efficiency. These machines feature a unique swing arm design, allowing for a versatile range of motion that facilitates intricate cuts and shapes. This adaptability is particularly advantageous when working with various materials, from textiles to metals, ensuring a clean and accurate finish that enhances product quality.

At the heart of these machines lies advanced technology, including programmable logic controls and sensor systems that monitor cutting parameters in real time. This integration of automation not only minimizes human error but also increases production speed. The hydraulic and pneumatic systems used in swing arm cutting machines further contribute to their performance, enabling them to exert consistent force and maintain stability during operation. As a result, manufacturers can achieve high levels of precision while reducing waste, ultimately driving down production costs and improving overall efficiency.

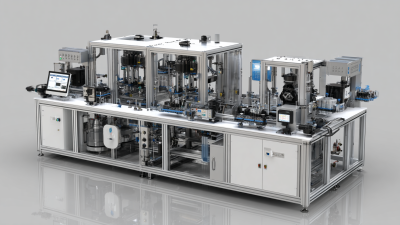

Swing arm cutting technology is transforming production lines by enhancing precision and efficiency in manufacturing processes. One of the key benefits of this technology is its ability to deliver consistent accuracy, ensuring that each cut meets exact specifications. This precision is invaluable in industries where tolerances are critical, helping manufacturers reduce waste and improve quality control. Moreover, the swing arm design allows for greater accessibility and versatility, enabling operators to handle a wider range of materials and shapes without compromising on performance.

Another significant advantage is the speed at which swing arm cutting machines operate. Their design minimizes downtime and increases throughput, allowing production lines to meet higher demands without sacrificing quality. This efficiency is particularly beneficial in competitive markets where time-to-market can determine success. By integrating swing arm cutting technology into their operations, manufacturers can not only enhance productivity but also gain a competitive edge, ensuring they stay ahead in rapidly evolving industries.

Swing arm cutting machines represent a significant advancement in modern manufacturing techniques, particularly when compared to traditional cutting methods. Unlike conventional cutting techniques that often rely on stationary blades and manual labor, swing arm machines feature a dynamic arm that can pivot and move in various directions. This design allows for enhanced precision and control, enabling manufacturers to achieve cleaner cuts and reduce material waste. The ability to adapt to different materials and thicknesses further solidifies the swing arm's position as a superior option in industries where efficiency and accuracy are paramount.

Additionally, the technological integration in swing arm cutting machines streamlines workflow and minimizes the potential for human error. Automation features, such as digital controls and programmable settings, provide operators with an intuitive interface to manage cutting operations effectively. In contrast, traditional cutting methods often necessitate multiple manual adjustments and can be labor-intensive, leading to increased production times and costs. This comparative analysis highlights how swing arm cutting machines not only enhance productivity but also contribute to higher standards of quality and consistency in the final products.

The integration of automation in swing arm cutting systems has heralded a new era of precision in modern manufacturing. With industries increasingly leaning towards efficiency and quality, the demand for cutting-edge technology has surged. According to a report by MarketsandMarkets, the global market for automated cutting machines is expected to reach $7.3 billion by 2026, growing at a CAGR of 4.8%. This trend highlights how businesses are recognizing the importance of precision cutting in enhancing productivity and reducing waste.

Swing arm cutting machines exemplify the culmination of advanced engineering and automation. These systems are designed to deliver consistent results, minimizing human error while maximizing throughput. For instance, a study from the International Journal of Advanced Manufacturing Technology noted that automated cutting systems can improve cutting accuracy by up to 95% compared to manual methods. This level of precision not only ensures the perfect fit of components but also significantly lowers material costs, leading to more sustainable manufacturing practices. The future of manufacturing lies in such intelligent systems, enabling industries to meet ever-increasing consumer demands for quality and efficiency.

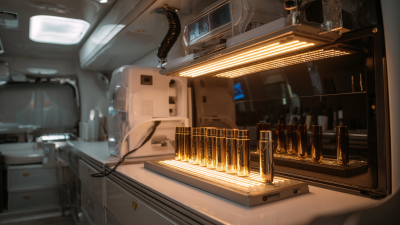

Swing arm cutting machines have become indispensable in modern manufacturing, demonstrating significant advancements that enhance precision and productivity. According to a recent report by MarketsandMarkets, the global market for cutting machines is projected to reach $6.5 billion by 2025, driven by innovations in swing arm technology. These machines, renowned for their versatility and efficiency, enable manufacturers to reduce waste and improve overall production rates, addressing the growing demand for high-quality products at lower costs.

As we look toward the future, the integration of smart technologies into swing arm cutting systems is set to revolutionize the industry further. Industry trends indicate that manufacturers are increasingly adopting IoT-enabled devices, which allow for real-time monitoring and data analysis. This shift not only enhances operational efficiency but also facilitates predictive maintenance, ultimately extending the lifespan of cutting equipment. According to a report from Grand View Research, the adoption of automation in manufacturing, including swing arm cutting technologies, is expected to grow at a CAGR of over 12% from 2021 to 2028, signifying a transformative shift that could reshape industrial processes worldwide.