In today's fast-paced manufacturing environment, the efficiency of operations is paramount, especially in industries reliant on precision and productivity. The Hydraulic Cutting Press stands out as a critical piece of equipment that can significantly enhance operational efficiency. According to a 2021 report by Grand View Research, the global hydraulic press market was valued at over $7 billion, with a projected growth rate of 4.5% annually. This growth underscores the increasing reliance on hydraulic technology for its ability to deliver high force in cutting processes, thereby optimizing material use and reducing waste. Implementing a Hydraulic Cutting Press not only streamlines production but also aligns with the industry’s push towards sustainability and cost-effectiveness. As manufacturers seek competitive advantages, understanding how to maximize the capabilities of these presses becomes essential for improving overall operational efficiency.

Hydraulic cutting press technology is a vital component in modern manufacturing, offering precision and efficiency for various applications. At its core, a hydraulic cutting press operates by using hydraulic fluid under pressure to generate the force needed to cut through materials. This technology is particularly advantageous due to its ability to deliver consistent and controlled power, allowing for intricate designs and complex shapes without compromising material integrity.

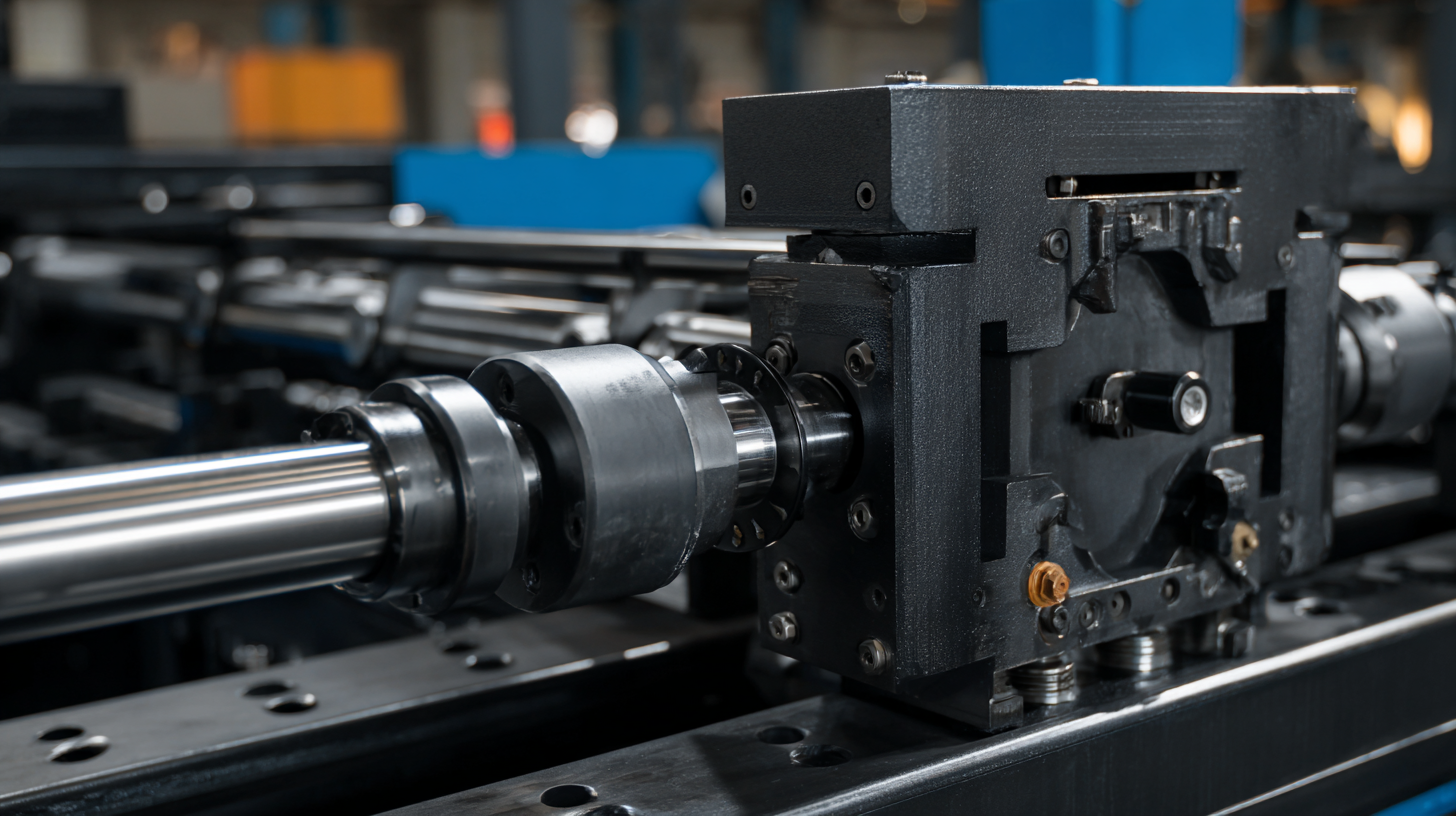

Understanding the basics of hydraulic cutting presses involves recognizing their main components, including the hydraulic cylinder, the cutting die, and the control system. The hydraulic cylinder is responsible for converting hydraulic energy into mechanical force, while the cutting die determines the shape and size of the cut. Efficient operation hinges on maintaining optimal hydraulic fluid levels and ensuring all components are well-maintained. By mastering these fundamentals, operators can significantly enhance their productivity, reduce waste, and achieve superior results in their cutting operations.

Hydraulic cutting presses are pivotal in various industries, providing precision and efficiency in processing materials. According to a report by Grand View Research, the global hydraulic press market is anticipated to reach USD 4.41 billion by 2025, primarily driven by their applications in metal forming and plastic molding. In automotive manufacturing, hydraulic cutting presses enable the swift and accurate cutting of metal sheets, which is crucial for producing components like body panels and chassis parts. This automation not only enhances production rates but also ensures consistent quality, reducing waste and operational costs.

In the textile industry, the need for high-speed cutting is met with hydraulic cutting presses designed specifically for fabric. The market for textile machinery, as highlighted by Research and Markets, is projected to grow substantially, reflecting a shift toward automation in cutting processes. Hydraulic presses allow for intricate designs and patterns while handling multiple layers of fabric simultaneously, significantly speeding up production cycles. Adopting such technology can potentially decrease labor costs by up to 30% and increase output by improving cycle times and reducing downtime for machinery.

This chart illustrates the efficiency improvements observed when utilizing hydraulic cutting presses across different industries, highlighting key applications and their effectiveness.

To maximize efficiency with a hydraulic cutting press, implementing best practices for maintenance and operational efficiency is paramount. According to a report by the Fabricators & Manufacturers Association (FMA), proper maintenance can increase equipment lifespan by up to 30%, significantly reducing downtime. Routine checks on hydraulic fluids, seals, and system pressure not only enhance performance but also prevent costly machine failures. Establishing a preventive maintenance schedule is essential, enabling your workforce to maintain high production levels while minimizing unexpected repairs.

Operational efficiency can be further improved by training staff on the optimal use of hydraulic cutting presses. A study published by the International Journal of Machine Tools and Manufacture indicates that well-trained operators can increase throughput by as much as 25%, simply by adhering to standardized operating procedures. Encouraging team members to share insights on machine settings and production techniques fosters a culture of continuous improvement. By leveraging these strategies, businesses can not only enhance their operational efficiency but also ensure their hydraulic cutting presses function at peak performance, ultimately leading to greater productivity and profitability.

Optimizing material handling is essential to enhance the performance of a hydraulic cutting press in any operational setting. Efficient material handling begins with a thorough assessment of workflow, ensuring that materials are delivered to the cutting press in a sequential and organized manner. By streamlining the process—such as utilizing automated guided vehicles or conveyor systems—operators can minimize downtime and reduce the risk of manual handling errors. This proactive approach not only speeds up production but also maintains the integrity of materials, leading to higher quality cuts.

Furthermore, implementing proper storage solutions can significantly improve material accessibility. Utilizing vertical storage systems or designated shelving for raw materials aids in quick retrieval and lessens the time spent searching for items. In addition, regular maintenance and calibration of the hydraulic cutting press itself are crucial for optimal performance. Ensuring that the machine is in peak condition allows for efficient operation and leads to better material handling practices, ultimately maximizing overall productivity in the manufacturing process. By focusing on these aspects of material handling, businesses can enhance the capabilities of their hydraulic cutting press and ensure greater operational efficiency.

Training and workforce development for hydraulic press operators is essential to maximize efficiency and safety in operations. According to the Fabricators and Manufacturers Association (FMA), investing in workforce training can lead to productivity increases of up to 20%. This highlights the critical role that well-trained operators play in reducing downtime, minimizing waste, and improving overall process efficiency. As hydraulic cutting presses become more advanced, operators must possess a comprehensive understanding of not just the equipment but also the materials and processes involved.

To ensure optimal performance and safety, companies should implement a structured training program focusing on both theoretical and hands-on experience. For example, periodic workshops that cover topics such as hydraulic systems, troubleshooting, and maintenance can significantly enhance operator competency. Additionally, incorporating simulation-based learning can prepare operators to handle real-life scenarios effectively.

Tips: Encourage collaboration among operators to share best practices and experiences. Regularly assess operator skills through evaluations and provide refresher courses as needed. Host industry certification programs to keep your workforce updated on the latest technologies and safety standards, thus driving both performance and compliance within your operations.