In the ever-evolving landscape of composite manufacturing, advanced technologies such as the Ud Prepreg Machine are revolutionizing the industry. As we move into 2025, understanding the functionality and applications of the Ud Prepreg Machine becomes crucial for manufacturers looking to enhance efficiency and product quality. This guide aims to provide a comprehensive overview of the principles behind these machines, their operational mechanisms, and their impact on production processes.

The Ud Prepreg Machine stands at the forefront of composite material processing, enabling businesses to create high-performance components with precision and consistency. By utilizing the benefits of prepreg materials, this machine simplifies the manufacturing process while ensuring superior material properties. Throughout this guide, we will explore the technical specifications, operational best practices, and the future trends associated with Ud Prepreg Machines, equipping readers with the knowledge needed to leverage this technology effectively.

As industries across aerospace, automotive, and other sectors increasingly adopt advanced composite solutions, understanding the capabilities and advantages of the Ud Prepreg Machine will empower businesses to remain competitive and innovative. From initial setup to optimizing production workflows, this guide will serve as a valuable resource for anyone looking to harness the potential of this cutting-edge technology in 2025 and beyond.

In 2025, Ud prepreg machines have become a pivotal technology in manufacturing, particularly within the aerospace and automotive industries. These machines utilize advanced composite materials, which are pre-impregnated with resin, offering significant benefits in terms of strength, weight reduction, and manufacturing efficiency. The precision and control provided by Ud prepreg machines allow for the creation of complex structures that were previously unattainable, leading to innovations in design and functionality.

Tips: When operating Ud prepreg machines, always ensure that proper calibration and maintenance are performed regularly. This not only extends the lifespan of the machine but also maximizes the quality of the final product. Additionally, it’s essential to closely monitor the temperature and humidity levels in the workspace to maintain optimal conditions for the materials being used, as this can greatly affect the curing process.

As we look into the importance of Ud prepreg machines, their role in sustainability cannot be overlooked. By utilizing more efficient materials and processes, manufacturers can significantly reduce waste and energy consumption. Implementing rigorous quality control measures during production can also lead to better resource management, minimizing the environmental footprint of manufacturing practices.

Tips: Investing in training for operators can provide a deeper understanding of the technology, ensuring that they can troubleshoot issues effectively and use the machines to their full potential. Regular workshops or updated training sessions can keep the workforce knowledgeable about the latest advancements in prepreg technology.

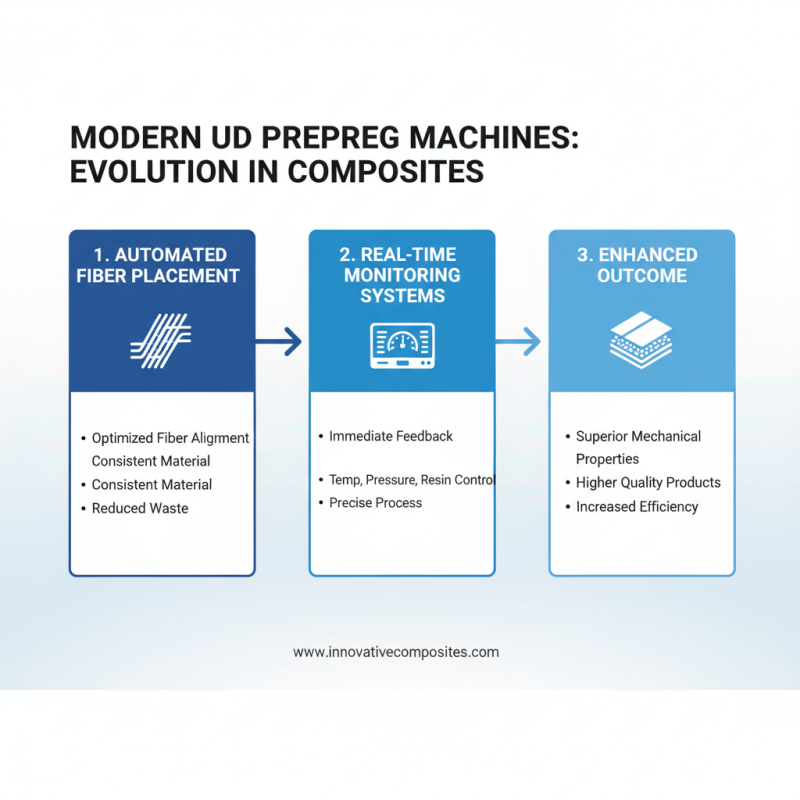

Modern UD prepreg machines have evolved significantly, integrating advanced technologies to enhance efficiency and quality in composite manufacturing. One of the key features is the automated fiber placement system, which optimizes the alignment and layering of unidirectional fibers. This technology ensures consistent material distribution, reducing waste and improving the mechanical properties of the final product. Additionally, the integration of real-time monitoring systems provides operators with immediate feedback on temperature, pressure, and resin infusion levels, allowing for precise control over the prepreg process.

Another notable advancement in UD prepreg machines is the introduction of smart manufacturing capabilities. This includes the use of artificial intelligence and machine learning algorithms to predict process outcomes and optimize settings for different materials and conditions. These intelligent systems can analyze historical data to make recommendations for adjustments, improving the overall production cycle and minimizing downtime. Furthermore, enhanced user interfaces featuring touchscreen controls and intuitive software simplify operation, making it accessible even to those with limited experience in composite manufacturing. This combination of features not only streamlines the workflow but also elevates the production quality, making modern UD prepreg machines indispensable in various high-performance applications.

Operating Ud prepreg machines effectively requires a clear understanding of their components and functions. Start by familiarizing yourself with the machine’s interface. This often includes controls for temperature, pressure, and vacuum levels, which are crucial for preparing prepreg materials efficiently. Before beginning operation, ensure all safety protocols are in place, including the use of personal protective equipment. Thoroughly review the manufacturer's guidelines to understand the specific features of your machine model.

Once you are prepared, the loading process is essential. Carefully place the prepreg material into the machine, ensuring that it is evenly distributed and free from any folds or wrinkles. Set the appropriate temperature and vacuum settings, as these will significantly impact the quality of the final product. Pay attention to the curing cycle, making adjustments based on the thickness and type of materials being used. Regularly monitor the machine during operation to detect any irregularities early on, facilitating timely interventions to maintain optimal performance.

The aerospace and automotive industries are witnessing a surge in the application of UD prepreg machines, driven by their ability to produce lightweight, high-strength composite materials. According to the Composite World Global Market Report, the demand for carbon fiber composites in aerospace is projected to reach $5.73 billion by 2025. UD prepregs are pivotal in this growth, as they enhance the performance characteristics of components such as fuselages and wings, ensuring they meet stringent safety and efficiency standards while reducing overall weight.

In addition to aerospace, the sports and recreation sectors are leveraging UD prepreg technologies for applications ranging from high-performance bicycles to tennis rackets. A report by the Freedonia Group indicates that the market for reinforced thermoset resin composites in the sports industry will experience an annual growth rate of over 4% through 2026. The unique properties of UD prepregs, such as their uniform fiber alignment and ability to be molded into complex shapes, make them an ideal choice for manufacturers focused on innovation and performance enhancement in their products. As industries continue to evolve toward lightweight solutions, the versatility of UD prepreg machines will play a critical role in shaping the future of composite manufacturing.

Maintaining and troubleshooting UD prepreg machines is essential for ensuring optimal performance and longevity. Regular maintenance routines should include checking the alignment of rollers, inspecting temperature control systems, and reviewing the pressure settings. Developing a schedule for routine maintenance can prevent unexpected breakdowns. It's advisable to keep a detailed log of all maintenance activities, which can help in identifying patterns that may indicate underlying issues.

In cases of malfunction, diagnosing the problem systematically is crucial. Begin by reviewing the machine's operational manual for specific error codes or symptoms. Common issues may arise from the resin cure process or inconsistencies in material feed. A thorough inspection of electrical connections and pneumatic systems can also reveal potential problems. Implementing a checklist during troubleshooting can streamline the process, ensuring that all components are assessed efficiently. By prioritizing both preventive maintenance and effective troubleshooting strategies, operators can enhance the reliability of UD prepreg machines.