In the ever-evolving landscape of manufacturing and packaging, the importance of selecting the right Die Cutting Press cannot be overstated. As industries continue to embrace advancements in technology, the demand for precision and efficiency in die cutting processes has reached new heights. In 2025, choosing the ideal Die Cutting Press involves a nuanced understanding of various factors that influence performance, reliability, and adaptability.

Considerations such as the machine's production capacity, the materials it can handle, and its compatibility with modern software systems play a critical role in making an informed decision. Furthermore, evaluating the long-term operational costs, maintenance requirements, and support services available can significantly affect the overall efficiency and productivity of your business. As we delve into the key factors to consider, it becomes evident that a strategic approach to selecting a Die Cutting Press is essential for businesses looking to enhance their production capabilities and stay competitive in a rapidly changing market.

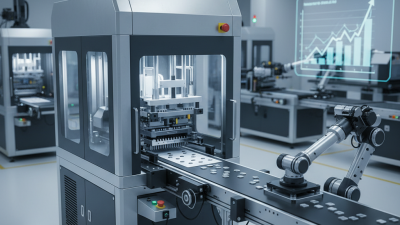

In 2025, the selection of a die cutting press will be heavily influenced by several key technologies that enhance efficiency and precision in manufacturing. One of the primary technologies to consider is automation. Advanced automation systems can streamline operations, reduce manual intervention, and increase production speed, allowing businesses to respond quickly to market demands. This not only optimizes workflow but also minimizes the risk of human error, leading to more consistent output quality.

Another critical factor is the integration of smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). These innovations allow for real-time monitoring and predictive maintenance, which can significantly reduce downtime and enhance operational efficiency. With smart sensors and analytics, manufacturers can gather data on machine performance, enabling informed decision-making regarding maintenance schedules and operational adjustments. As these technologies continue to evolve, they will play a pivotal role in determining the overall effectiveness of die cutting presses in diverse applications.

Moreover, advancements in cutting technology, such as laser die cutting, are also reshaping the landscape. This method offers higher precision and flexibility, making it ideal for intricate designs and a variety of materials. As businesses increasingly seek to diversify their product offerings and incorporate complex patterns, investing in presses that support these cutting-edge techniques will become essential.

When selecting a die cutting press, material compatibility is one of the most critical factors to consider. Different materials respond uniquely to the die cutting process, affecting the efficiency and quality of the output. For instance, softer materials like paper or thin plastic may require a different type of die and cutting pressure compared to tougher materials such as leather or rubber. Understanding the specifications of the materials you plan to work with will inform your choice of press, ensuring it can handle your desired applications with precision.

**Tips:** Always test different thicknesses and types of materials to see how they react to the die cutting process before making a final decision on your equipment. This not only helps you gauge the effectiveness of the die cutting press but also allows you to optimize your settings for various materials to achieve the best results. Additionally, consider the potential need for customization in your dies to accommodate a broader range of material types in the future.

Furthermore, examine the press's compatibility with various die sizes and shapes, as this will directly impact your production capabilities. Some materials may require intricate designs that need specific die configurations to ensure clean cuts. Investing time in researching and evaluating these factors will ultimately lead to better, more consistent production outcomes.

| Material Type | Die Cutting Capability | Maximum Thickness (inches) | Recommended Press Type | Typical Applications |

|---|---|---|---|---|

| Paper | High Precision | 0.25 | Hydraulic | Card Making, Packaging |

| Cardboard | Moderate Precision | 0.5 | Mechanical | Box Construction, Displays |

| Foam | High Volume | 1.0 | Rotary | Packaging, Craft Projects |

| Leather | High Quality | 0.75 | Digital | Bags, Apparel |

| Plastic | Flexible | 0.3 | Servo | Containers, Prototypes |

When considering the purchase of a die cutting press in 2025, assessing production volume and efficiency needs is paramount. Different operations have varying demands, and aligning your die cutting press to these requirements can lead to significant benefits. For businesses that anticipate a high production volume, selecting a press that offers rapid changeover times and the capability to handle larger jobs can enhance workflow efficiency. Factors such as throughput rates and setup times should be meticulously evaluated to ensure that the press meets or exceeds the expected production demands.

Additionally, assessing efficiency needs encompasses not only the speed of production but also the quality of output. A die cutting press that incorporates advanced technology can improve accuracy and reduce waste, resulting in a more streamlined operation. Understanding the materials you will work with and how they impact the cutting process is crucial; different substrates may require specific configurations for optimal performance. Ultimately, a careful analysis of both volume requirements and efficiency capabilities will guide the selection of a die cutting press that not only meets current demands but is also adaptable for future growth.

When selecting a die cutting press in 2025, understanding the cost and budget considerations is crucial. The die cutting industry has seen significant advancements, with reports indicating an average expenditure on cutting equipment rising by approximately 15% over the past two years. Factors such as machine specifications, materials used, and manufacturing processes impact costs substantially. For instance, a press that offers enhanced precision and durability may require a higher upfront investment but could result in lower operational costs over time due to reduced material waste and maintenance needs.

When budgeting for a die cutting press, it is essential to evaluate both the purchase price and long-term operational costs. According to a recent industry survey, nearly 30% of businesses reported underestimating ongoing maintenance expenses, which can account for 10-20% of the initial purchase price annually. Therefore, allocating a portion of your budget for maintenance and potential upgrades is advisable.

**Tips:** Consider analyzing your production volume and cycle times to assess the right press for your needs, as this will affect overall return on investment. Additionally, engage with industry professionals to gain insights into total cost of ownership, ensuring you select a machine that aligns not just with your current demands but with future growth as well.

The chart above illustrates the importance of various factors to consider when choosing a die cutting press in 2025. Each factor is rated on a scale from 1 to 10 based on its relevance to potential buyers.

When choosing a die cutting press in 2025, one of the most critical factors to consider is the level of supplier support and warranty services. A reliable supplier goes beyond just selling equipment; they provide ongoing assistance that can significantly impact your production efficiency and overall business success. Ensuring you have access to technical support when faced with operational challenges is vital. A responsive supplier can help troubleshoot issues quickly, minimizing downtime and keeping your production line moving.

Additionally, warranty services play a crucial role in safeguarding your investment. A robust warranty can cover repairs, part replacements, and maintenance for a certain period, offering peace of mind as you integrate the die cutting press into your manufacturing process. Understanding the warranty terms and the extent of coverage can help you avoid unexpected costs. In some cases, suppliers may also offer extended warranties or service contracts for additional protection, making it essential to evaluate these options as part of your purchasing decision. By considering supplier support and warranty services, you can make a well-informed choice that supports your operational needs and enhances your overall productivity.