In today’s fast-paced manufacturing landscape, selecting the right Hot Melt Coating Machine is crucial for optimizing production efficiency and ensuring product quality. As industries evolve, so do the technologies that support them, leading to a wide array of options tailored to specific needs and applications. Whether you require a machine for packaging, automotive, or textile industries, understanding the different types of Hot Melt Coating Machines and their features can significantly impact your operational effectiveness.

In this blog, we will evaluate various models, highlighting key factors such as application versatility, speed, reliability, and maintenance requirements. By the end, you will be equipped with valuable insights to help you determine which Hot Melt Coating Machine best suits your unique manufacturing demands.

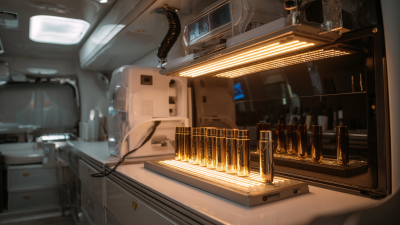

Hot melt coating machines play a crucial role in various industries, providing seamless coating solutions that enhance product performance. These machines utilize thermoplastic materials that melt and adhere to substrates, creating a strong bond that is both durable and effective.

Key features to consider when evaluating hot melt coating machines include the type of application method (such as slot die, curtain coater, or spray systems), temperature control, and the ability to manage different viscosities of hot melt adhesives. According to a recent industry analysis by Freedonia Group, the global market for hot melt adhesives is projected to reach $8.83 billion by 2026, signifying the importance of investing in high-quality coating technology.

When selecting a hot melt coating machine, it's essential to assess your specific needs. For example, if you're producing a high volume of products, opt for a machine with faster application speed and efficient cleanup features. Additionally, consider the machine's versatility in handling various substrate materials, as this can significantly impact your production line's flexibility.

Tips: Always check for energy-efficient models, as they can substantially reduce operational costs. Furthermore, prioritize machines that offer user-friendly interfaces for easier monitoring and adjustments during production. Investing in comprehensive training and support from the manufacturer can also enhance operational efficiency and minimize downtime.

When evaluating hot melt coating machines, it’s essential to understand the different types available on the market to determine which system best meets your needs. The three primary categories include slot-die, gravure, and spray coating machines, each offering unique advantages depending on application requirements. According to a report by Smithers Pira, the market for hot melt adhesives is expected to grow at a CAGR of 6.2%, emphasizing the increasing demand for various coating technologies across sectors such as packaging, automotive, and electronics.

Slot-die coating machines are widely used for their precision and ability to apply uniform coatings on both flat and irregular surfaces. They are particularly favored in industries requiring tight tolerances, such as electronics manufacturing, where the average film thickness can range as low as 5 to 10 microns. Alternatively, gravure coating is recognized for its efficiency in high-speed applications, making it ideal for large-scale production runs. This method can achieve coating speeds exceeding 300 meters per minute, which appeals to the packaging industry where speed and consistency are crucial.

Spray coating machines offer versatility by accommodating a variety of substrates and thicknesses. They are especially useful in applications like automotive where more intricate shapes need to be coated. Current research indicates that advancements in spray technology can improve material utilization rates by up to 30%, providing significant cost savings and waste reduction. Evaluating these options based on your specific production volume, substrate type, and desired application will guide you in selecting the hot melt coating machine that best aligns with your operational goals.

When assessing which hot melt coating machine is best for your needs, several key factors are essential to consider. The technological advancements in this industry play a significant role, as machines are increasingly designed to enhance efficiency while meeting sustainability goals. As businesses shift towards greener manufacturing processes, selecting a machine that integrates energy-saving features and recyclable materials can greatly impact operational costs and environmental footprint.

When assessing which hot melt coating machine is best for your needs, several key factors are essential to consider. The technological advancements in this industry play a significant role, as machines are increasingly designed to enhance efficiency while meeting sustainability goals. As businesses shift towards greener manufacturing processes, selecting a machine that integrates energy-saving features and recyclable materials can greatly impact operational costs and environmental footprint.

Tip: Prioritize machines that offer multiple coating options and are equipped with smart technology for precise application. This not only reduces waste but also ensures consistency in production quality. Additionally, look for machines that have been designed with maintenance in mind—easy access to parts and user-friendly interfaces can greatly reduce downtime.

Market trends also indicate a growing demand for machines that can adapt to changing production requirements. This versatility is crucial for companies aiming to remain competitive in a dynamic landscape. Investing in a hot melt coating machine that can handle various substrates and adhesion needs will provide greater flexibility in operations.

Tip: Consider the after-sales support and training offered by manufacturers. A reliable supplier should provide not only quality machinery but also the resources necessary to maximize your investment's potential.

When it comes to hot melt coating equipment, maintenance and care are paramount for ensuring optimal performance and longevity. Just as with non-ferrous furnaces, setting up a diligent cleaning and maintenance schedule can significantly prolong the life of your machinery. Regularly adhering to the maintenance guidelines outlined in the equipment's manual will not only keep the machines in peak condition but also enhance their efficiency in production processes.

Incorporating routine inspections and cleaning can prevent small issues from escalating into costly repairs. Dust and residue can accumulate, affecting the heating elements and application precision of hot melt coating machines. Therefore, developing a cleaning schedule is essential. Simple practices such as wiping down surfaces, checking for wear and tear, and replacing worn components can make a noticeable difference. Keeping these machines well-maintained helps ensure they deliver high-quality outputs, ultimately improving your manufacturing workflow.

In recent years, hot melt coating technology has gained significant traction across various industries, thanks to its adaptability and efficiency in real-world applications. The shift towards advanced materials and processes is evident, particularly in regions like Guangdong, where over 20 exemplary enterprises have demonstrated impressive production capabilities. The focus on "new quality productivity" in 2024 emphasizes the importance of innovative manufacturing solutions, including hot melt coatings, that enhance production quality and operational efficiency.

Moreover, advancements in powder coating technologies have illustrated how these methods are not only economically beneficial but also environmentally considerate. By minimizing waste and reducing costs, manufacturers are increasingly turning to these efficient coating solutions to boost their productivity. This trend aligns with the growing market demand for high gloss finishes and aesthetically pleasing products, without the need for traditional coating methods. As manufacturers explore the most suitable hot melt coating machines for their needs, understanding the real-world applications and benefits of these technologies becomes crucial for maintaining competitive advantages in the evolving market landscape.

| Machine Type | Max Speed (m/min) | Coating Thickness (mm) | Temperature Range (°C) | Application Type |

|---|---|---|---|---|

| Roll Coater | 30 | 0.1 - 5.0 | 100 - 180 | Flexible Packaging |

| Spray Coater | 20 | 0.05 - 0.5 | 120 - 200 | Industrial Applications |

| Slot Die Coater | 25 | 0.1 - 3.0 | 160 - 220 | Electronics & Batteries |

| Blade Coater | 15 | 0.1 - 2.0 | 140 - 180 | Textiles & Paper |

| Extrusion Coater | 10 | 0.5 - 4.0 | 160 - 220 | Construction & Insulation |