In the realm of manufacturing and material processing, the implementation of advanced techniques such as Thermohydraulic Coating Automatic Cutting has transformed the way we approach precision cutting and surface treatment. This innovative method not only enhances the efficiency of cutting operations but also significantly improves the quality of the finished products. The synergistic effect of thermohydraulic coating combined with automated cutting processes allows for a high degree of accuracy while simultaneously reducing labor costs and time.

As industries increasingly prioritize sustainability and efficiency, the adoption of Thermohydraulic Coating Automatic Cutting techniques provides a strategic advantage. By facilitating improvements in operational workflows, these techniques can lead to heightened productivity and product lifespan. Furthermore, the inherent adaptability of such technologies enables businesses to meet the evolving demands of diverse applications across multiple sectors.

In this article, we will explore the best practices and tips for effectively implementing Thermohydraulic Coating Automatic Cutting techniques. By understanding core principles and methodologies, professionals can harness the full potential of these technologies to drive innovation and improve outcomes in their respective industries.

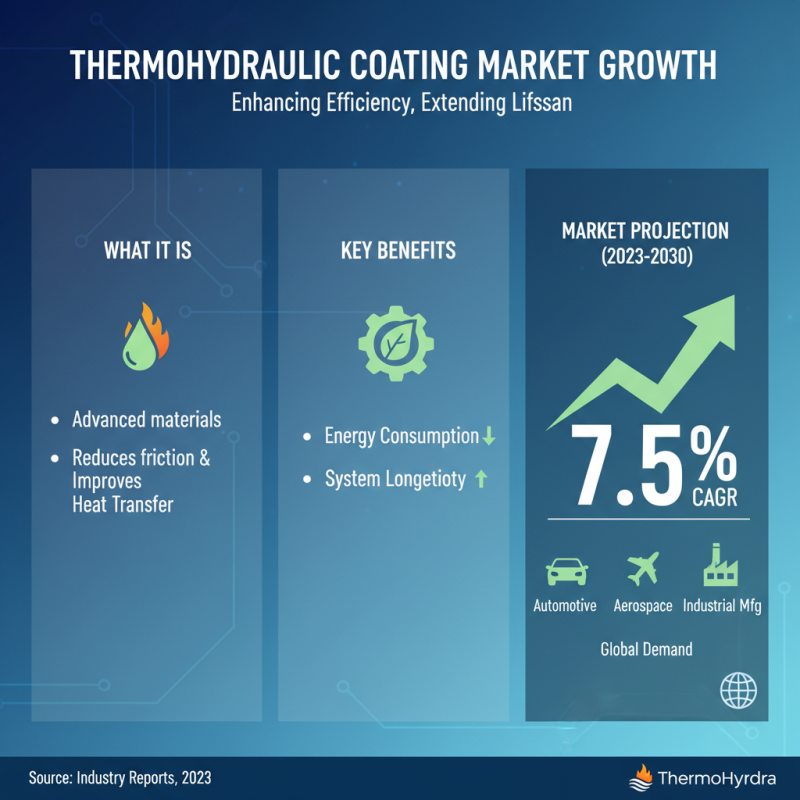

Thermohydraulic coating involves the application of coatings that enhance thermal efficiency and hydraulic performance, making them essential in various industrial applications. By employing advanced materials that reduce friction and improve heat transfer, these coatings significantly impact energy consumption and system longevity. Recent reports indicate that the thermohydraulic coating market is projected to grow at a CAGR of 7.5% from 2023 to 2030, reflecting rising demand across sectors such as automotive, aerospace, and industrial manufacturing.

Understanding the principles of thermohydraulic coating is crucial for optimizing its applications. These coatings often utilize a combination of polymers and metallic compounds to create surfaces that not only withstand extreme temperatures but also resist corrosion and wear. For example, studies have shown that coatings with thermal conductivity exceeding 300 W/mK can enhance engine performance and reduce emissions by improving overall thermal management. Furthermore, the strategic application of these coatings in hydraulic systems can lead to efficiency increases of over 20%, highlighting their vital role in modern engineering solutions.

In the realm of thermohydraulic coatings, precision in automatic cutting techniques has emerged as a pivotal factor driving both efficiency and quality in manufacturing processes. According to a recent industry report from MarketsandMarkets, the global market for automated cutting technologies is expected to grow to $4.1 billion by 2026, underscoring the increasing emphasis on accuracy and automation. Effective cutting techniques can reduce material waste by up to 30%, a significant cost saving in production cycles. This highlights the necessity for manufacturers to adopt precision-oriented methods that ensure a clean and efficient cut, ultimately enhancing the performance of coatings.

Furthermore, precision in cutting not only affects material usage but also impacts the overall quality and durability of coatings applied. A study published by the Journal of Coatings Technology and Research notes that improper cutting techniques can lead to flawed coatings, which may only last 70% as long as those produced through precise methods. The perfect synergy of automatic cutting and coating application can lead to superior surface finishes and improved thermal insulation properties, crucial for thermohydraulic applications in various industries. Investing in high-precision automatic cutting techniques is therefore paramount for manufacturers aiming to achieve competitive advantages and exceed industry standards.

| Technique | Precision Level (%) | Material Type | Thickness (mm) | Speed (m/min) |

|---|---|---|---|---|

| Laser Cutting | 98 | Steel | 1.5 | 15 |

| Plasma Cutting | 95 | Aluminum | 3.0 | 12 |

| Waterjet Cutting | 90 | Composite | 5.0 | 8 |

| Oxy-fuel Cutting | 85 | Cast Iron | 10.0 | 6 |

Thermohydraulic coatings play a critical role in enhancing the performance and longevity of various industrial components. Achieving optimal cutting performance in these coatings requires a deep understanding of several key factors. According to a recent study published in the Journal of Advanced Manufacturing Technology, the cutting speed and feed rate significantly influence the quality of the cut in thermohydraulic coatings. Specifically, it was found that increasing the cutting speed tends to produce smoother edges, while optimizing feed rates can help minimize tool wear, ultimately leading to more efficient workflow and reduced operational costs.

Another essential factor is the choice of cutting tools and techniques. The same study highlighted that tools designed with advanced coatings, such as TiAlN, can withstand the higher thermal loads associated with cutting through thermohydraulic materials. Additionally, maintaining proper coolant application can lower the temperature at the cutting edge, reducing thermal degradation and improving overall cutting performance. Industry reports indicate that implementing precise cutting techniques can enhance production efficiency by up to 15%, showcasing the importance of selecting the right parameters for successful machining operations.

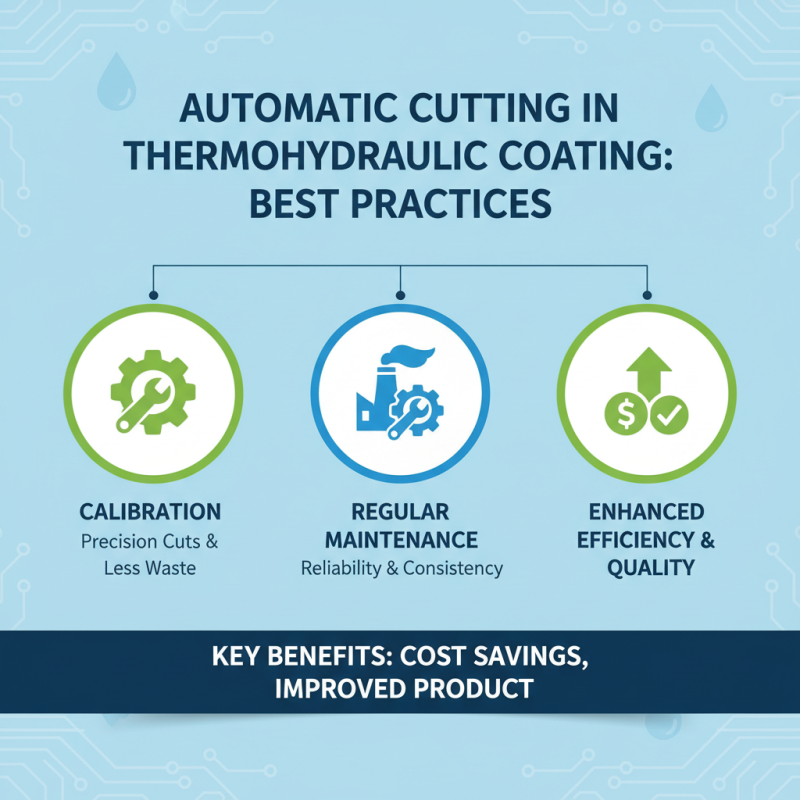

Effective implementation of automatic cutting techniques in thermohydraulic coating processes can significantly enhance production efficiency and product quality. One of the best practices to adopt is to ensure that the cutting equipment is calibrated correctly. Proper calibration not only allows for precision cuts but also minimizes material waste, leading to cost savings. Regular maintenance of the cutting machinery is equally important; a well-maintained system will operate more reliably and produce consistent results.

Another tip for effective automatic cutting is to choose the right cutting speed and feed rate. Understanding the material properties and the desired thickness of the coating can help in adjusting these parameters. This ensures that the cutting process is not only efficient but also does not compromise the integrity of the coated surfaces. Monitoring the cutting process in real-time can provide insights and allow for immediate adjustments, thereby optimizing the entire operation.

Lastly, training your workforce on the functionalities of the automatic cutting systems cannot be overstated. A knowledgeable team is crucial for troubleshooting and enhancing performance. Regular training sessions can keep staff updated on the latest techniques and encourage them to identify areas of improvement within the coating process. By focusing on these best practices, companies can leverage automatic cutting technologies to achieve better results in their thermohydraulic coating operations.

The field of thermohydraulic coating automatic cutting is witnessing rapid advancements, driven by emerging technologies that enhance precision and efficiency. With the integration of automation and artificial intelligence, recent innovations are enabling more accurate measurements and better control over cutting processes. For instance, advancements in laser cutting technology provide remarkable depth control and minimal thermal influence on the substrate, leading to improved finish quality. These new methodologies not only optimize material usage but also significantly reduce waste.

Moreover, the incorporation of real-time monitoring systems equipped with sensors and machine learning algorithms is transforming the way cutting processes are managed. These technologies allow for predictive maintenance and real-time adjustments, which enhance operational reliability. As a result, manufacturers can achieve higher operational throughput and reduce downtime. The exploration of new materials and cutting techniques, such as waterjet and plasma cutting, is also reshaping the landscape, making thermohydraulic coating applications more versatile and applicable in various industrial sectors. As this technology continues to evolve, it offers exciting possibilities for enhancing productivity and sustainability in manufacturing processes.