When choosing a Pu Coating Laminating Machine, it is crucial to consider specific factors. The right machine can significantly impact your production efficiency. But how do you know which one is best for your needs?

Begin by evaluating the machine’s specifications. Look for features such as speed, width, and thickness capabilities. These details will determine its suitability for your projects. However, it’s easy to get overwhelmed by choices. Not every machine will meet your expectations.

Also, consider the manufacturer's reputation. Research user reviews and feedback. Some brands promise high-quality but may fall short. A poorly reviewed machine can lead to frustrating experiences. Investing time in understanding your options will yield better results.

PU coating, or polyurethane coating, serves various industries with its unique properties. Its versatility makes it ideal for applications in automotive, textiles, and construction. According to a report by Research and Markets, the global polyurethane market was valued at approximately $60 billion in 2022 and is projected to grow at a CAGR of 5.5% through 2030. This growth reflects the demand for higher durability and protection in products.

The application of PU coating enhances surface protection and longevity. Industries use it to coat fabrics, providing water and stain resistance. In automotive applications, it protects against UV damage and corrosion. However, not all coatings are created equal. Some may not adhere well, leading to peeling or fading. This underlines the importance of understanding the specific needs of your application and the capabilities of the laminating machine used.

In textiles, PU coatings often provide a breathable yet waterproof barrier. However, improper application can compromise breathability, affecting comfort. Monitoring the manufacturing process is vital. A 2021 study indicated that improper curing times and temperatures can drastically reduce performance. Thus, achieving the right balance is crucial.

| Dimension | Specifications | Applications | Key Features |

|---|---|---|---|

| Production Speed | 20-50 m/min | Flexible packaging | High efficiency |

| Coating Thickness | 5-50 microns | Automotive interiors | Adjustable coat control |

| Heating Method | Electric or infrared | Textiles | Quick heating |

| Machine Size | Compact or large | Electronics | Space-saving designs |

| Weight | 500-2000 kg | Packaging | Sturdy construction |

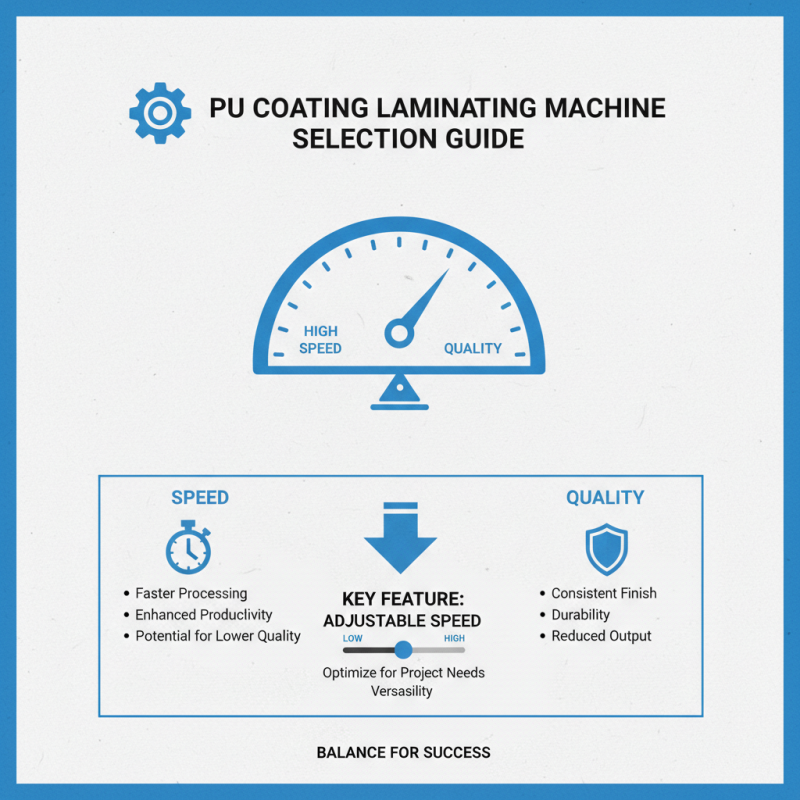

When selecting a PU coating laminating machine, several key features stand out. The machine's speed is crucial. Fast processing can enhance productivity. However, a higher speed may compromise coating quality. Strike a balance by reviewing specifications carefully. Look for a machine that offers adjustable speed settings. This flexibility can meet various project requirements.

Another important aspect is the heat and pressure control. Consistent heat distribution ensures uniform coating. Machines with adjustable pressure settings help achieve different textures. It’s essential to find a machine that allows you to fine-tune these settings. While advanced machines may seem appealing, they can be complex. Simplicity often leads to efficiency.

Durability is also worth considering. A robust build can withstand prolonged use. Yet, more durable machines may come with a hefty price tag. Reflect on your needs and budget. Sometimes, investing in a reliable model pays off in the long run. Regular maintenance is key to longevity, for any machine.

When evaluating PU coating laminating machines, the variety on the market can be overwhelming. These machines differ in technology and application. Some use roll-to-roll systems, while others operate with sheet-fed mechanisms. Each type has its pros and cons. For instance, roll-to-roll machines are known for high-speed production. However, they might struggle with thicker materials. According to a recent industry report, the global demand for PU coating solutions is projected to grow by 4.5% annually.

Another significant factor is the coat thickness. Some machines can apply a thickness ranging from 10 to 200 microns. This range may not suit all projects. If you’re working with delicate fabrics, a machine with better control over application may be necessary. Certain models might have limitations in precision. Many users report inconsistent results when pushing their machines to the limit.

Efficiency in energy use is also a key component. Some machines consume more power for increased output. However, this can lead to higher operational costs. A detailed analysis indicated that energy-efficient models could reduce electricity usage by up to 30%. Choosing the right machine involves balancing speed, quality, and energy consumption. It's crucial to align machine capabilities with production needs for optimal results.

When considering a PU coating laminating machine, evaluating the manufacturer's reputation is crucial. A reliable manufacturer ensures quality and consistency. According to recent industry reports, machines from reputable brands last longer and deliver better results. Users have reported a 25% increase in efficiency with machines from well-established manufacturers. This statistic highlights the importance of legacy and trust in machine selection.

Manufacturer support is another key factor. Technical assistance can save time and reduce downtime. A study found that 70% of companies faced delays due to insufficient support. Engaging with manufacturers that offer robust customer service can mitigate this risk. Look for companies that provide a thorough warranty and ongoing training. Even experienced users can struggle with new technology. Support should be readily available.

Research indicates that customer reviews often reflect real experiences. A significant number of users share that poor after-sales service led to ongoing issues. This feedback illustrates that a good product alone is not enough. It's the combination of quality machinery and dependable support that determines long-term success in operations. Make sure to analyze testimonials and seek out feedback, as these insights are invaluable.

When budgeting for a PU coating laminating machine, it’s vital to assess your needs carefully. The costs can vary significantly based on features and size. Consider how often you will use it. Is it for small projects or large production runs? Defining your usage can guide your budget effectively. A machine may seem affordable, but maintenance costs can add up.

Look into additional expenses. Supplies, such as PU films and adhesives, contribute to overall costs. These materials vary in price, so research suppliers. You might find cheaper alternatives, but ensure they meet your quality standards. Neglecting these details can lead to unexpected expenditures.

Reflect on your workspace. Do you have enough room for the machine? Installation costs might arise. Small workshops might need to make modifications to accommodate new equipment. Not considering this aspect can lead to unplanned expenses. Always, seek a balance between affordability and quality to make a wise investment.