Choosing the right Hydraulic Cutting Press can be daunting. With many options available, industry experts warn of the critical decisions ahead. Mike Anderson, a leading expert in the hydraulic press industry, once stated, "Selecting the right machine is half the battle." This highlights the importance of making an informed choice.

When considering a Hydraulic Cutting Press, it’s vital to assess your specific needs. Different models serve various purposes. For example, some machines excel in speed, while others focus on precision. You might find yourself torn between capabilities. Evaluating material types, thicknesses, and project requirements will guide your choice.

Yet, the journey isn't without challenges. Many buyers make impulse decisions. They might overlook essential factors, leading to regrets later. A well-chosen Hydraulic Cutting Press should not just meet current demands but adapt to future ones as well. Understanding your choices can save time and effort in the long run.

Hydraulic cutting presses are vital in many industries. They use hydraulic pressure to cut through various materials, from metals to plastics. Understanding their operation is essential for optimal usage. A recent report indicates that hydraulic cutting presses can achieve cutting forces up to 300 tons. This immense power allows for precise cuts, which is crucial in manufacturing.

When selecting a hydraulic cutting press, consider the material thickness and cutting speed. Many operators overlook these factors. An inefficient press can slow down production. According to industry studies, a poorly chosen machine can reduce productivity by 25%. This is significant for companies aiming for efficiency.

Calibration is another area needing attention. Machines must be calibrated to maintain accuracy. Inaccurate settings lead to waste and rework. The industry sees a staggering 30% of material wasted due to improper calibration. This highlights the importance of understanding basic principles. A well-informed choice can enhance performance while minimizing unnecessary costs. Instead of just focusing on power, think about overall effectiveness.

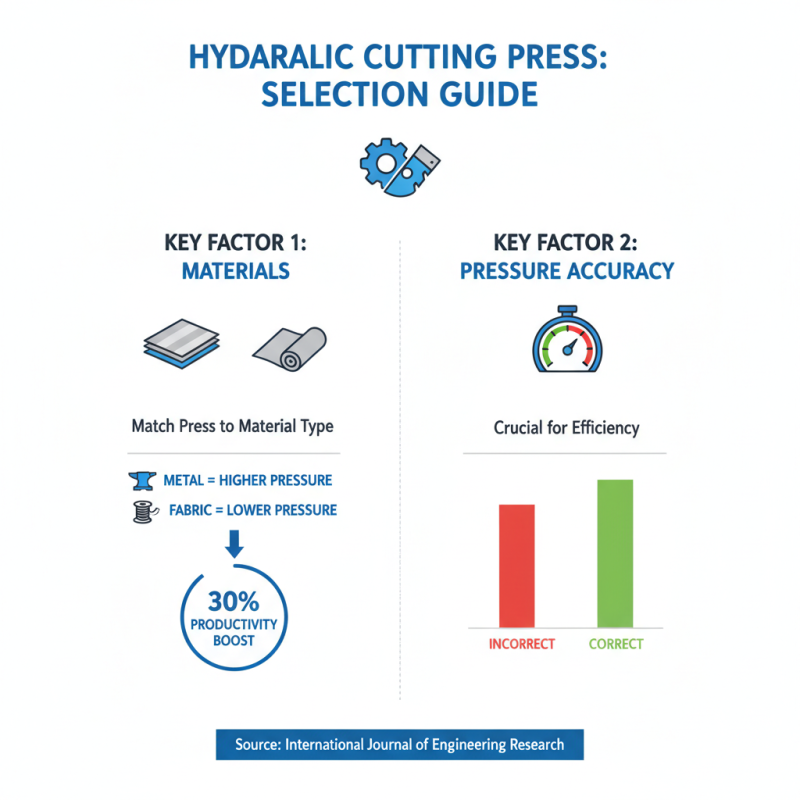

When selecting a hydraulic cutting press, understanding the key factors is crucial. First, consider the materials you will be cutting. Different materials require various pressure levels. For instance, cutting metal often needs higher pressure than fabric. A report from the International Journal of Engineering Research indicates that accurate pressure is vital for efficiency. Users reported a 30% increase in productivity when matching press specifications to materials correctly.

Next, evaluate the cutting size and capacity. The dimensions of the press should accommodate your largest workpiece. Oversized jobs lead to wasted time and resources. According to industry statistics, about 20% of companies experience delays due to inadequate press size. Lastly, look at the operation type. Some presses are manual, while others are fully automated. Automation can reduce labor costs but might involve a steeper learning curve. Flexibility in operation is necessary, as new tasks may arise that your current setup cannot handle.

Be aware that choosing a hydraulic cutting press is not always straightforward. Sometimes, cost constraints affect decisions. Cheaper presses may not offer the required power or precision. Also, maintenance needs can be underestimated, leading to unexpected downtime. Reflecting on these factors can aid in making a better-informed choice.

When selecting a hydraulic cutting press, assessing material compatibility is crucial. Different materials require tailored cutting forces and techniques. According to industry reports, materials like stainless steel and aluminum have distinct properties that influence cutting efficiency. For instance, stainless steel can require nearly twice the cutting force compared to softer alloys. Understanding these differences is vital for workflows involving diverse materials.

Additionally, thickness is a key factor. Hydraulic cutting presses work best within specified ranges. A report from a leading manufacturing association cites that presses should generally not exceed a thickness limit, or they risk damaging the tool or material. Operators often underestimate how material thickness impacts the cutting process.

Moreover, it’s essential to consider the lubricating properties of the material. Some materials may generate excess heat during cutting. Heat can warp components or cause tool wear. Evaluating this factor ensures smoother operations. Many users neglect this aspect and end up with lower efficiency and more operational errors. Reflecting on these details can lead to better decisions in purchasing hydraulic cutting presses.

| Material Type | Tensile Strength (MPa) | Recommended Pressure (MPa) | Cutting Speed (mm/s) | Suitability Rating |

|---|---|---|---|---|

| Aluminum | 70 | 8 | 20 | High |

| Carbon Steel | 400 | 15 | 10 | Medium |

| Stainless Steel | 500 | 20 | 5 | Low |

| Acrylic | 60 | 5 | 30 | High |

| Wood | 40 | 4 | 25 | Medium |

Choosing the right hydraulic cutting press requires careful evaluation of press capacity and specifications. The capacity you need largely depends on the material types and thicknesses you will work with. For example, a press with a capacity of 50 tons may handle materials up to 0.5 inches thick. However, pushing materials beyond their limits could lead to equipment failure and inefficiency.

It’s important to consider tonnage ratings carefully. According to industry reports, a hydraulic press can typically provide between 10 to 200 tons of force. That range should be matched with your specific application. For manufacturers working with metal, higher tonnage may be necessary due to material density.

**Tip:** Always calculate the expected load in real-world conditions. Many overlook the importance of this task.

Another critical specification is the stroke length. A longer stroke allows for deeper cuts and larger materials. However, a lengthy stroke can slow down the operation. According to recent findings, standard stroke lengths range from 4 to 12 inches. You need to balance between depth and speed based on production requirements.

**Tip:** Monitor productivity closely. Sometimes the ideal specs lead to unforeseen slowdowns. Keep a checklist for specifications and adjust as needed.

When selecting a hydraulic cutting press, maintenance and safety features are paramount. A well-maintained press ensures consistent performance. Look for machines with easy access to components, allowing for straightforward cleaning and repairs. Routine inspections should be simple, as this reduces downtime and enhances efficiency.

Safety features cannot be overlooked. Emergency stop buttons and safety guards should be standard. These features protect operators from accidental injuries. Furthermore, consider the locking mechanisms that prevent unauthorized access while machines are operational. Pay attention to user training programs as well. Proper training minimizes accidents and improper use.

Consider how often maintenance is required. Some presses need frequent check-ups, while others allow longer intervals. Think about your operation's workload. A busy environment might necessitate a more robust maintenance plan. Reflect on the potential costs associated with downtime. Balancing efficiency and safety is critical. You might realize that the perfect balance doesn’t exist and requires revisiting after purchase.