In the competitive world of manufacturing, choosing the right PVC Coating Laminating Line is crucial. According to a recent report by the Global Plastics Industry, the demand for PVC coatings has grown by 15% annually. This highlights the increasing importance of these lines in various applications. Industry expert John Smith emphasizes, “Investing in the right equipment is key to maximizing efficiency and output.”

Selecting an ideal PVC Coating Laminating Line can be challenging. Numerous factors come into play, such as production capacity, energy consumption, and material compatibility. Each operation has specific needs, and failing to consider them may lead to inefficiencies. It’s essential to assess both current and future production requirements.

Many businesses overlook the potential for customization. A standardized approach may not fit all needs. Without a tailored solution, companies risk falling short of their production goals. Seeking expert guidance when exploring options can address these nuances and improve overall output. Careful consideration can pave the way for growth in a dynamic market.

PVC coating laminating lines play a crucial role in various industries. These machines are essential for enhancing the durability and aesthetic appeal of materials. Understanding their functionalities can help you make informed decisions.

When exploring PVC coating laminating lines, consider the specific needs of your production process. Look for features like coating speed, temperature control, and thickness adjustment. These factors can greatly affect the outcome of your project. Pay attention to the machinery’s adaptability to different materials. Versatility can be a double-edged sword; while it increases efficiency, it may also complicate operation.

Installation and maintenance should not be overlooked. Ensure that the line fits into your existing setup. Sometimes, configurations might not align well, leading to unexpected challenges. Regular maintenance is key to sustaining performance. Skipping this can result in decreased output quality. Engaging with the right technicians can help keep issues at bay.

When selecting a PVC coating laminating line, several key factors come into play. First, consider the line's production capacity. You need to assess your current and future production needs. Too small a line will restrict growth. However, choosing a line that is too large can lead to wasted resources.

Another crucial aspect is the technology used in the laminating process. Older machines may offer lower upfront costs but can lead to inefficiencies. Their maintenance might also become a burden over time. Modern lines typically feature automation that can minimize labor costs. Yet, they may require a steeper initial investment.

**Tips:** Always evaluate the energy consumption of the line. Energy-efficient models save costs in the long run. Inspect and compare the warranty and technical support options. A good warranty indicates the manufacturer’s confidence.

Lastly, consider scalability. Your business needs may change, and your laminating line should adapt to those changes. Investing in a flexible line may be wise, even if it’s pricier. Don't rush into a decision—take time to analyze all factors.

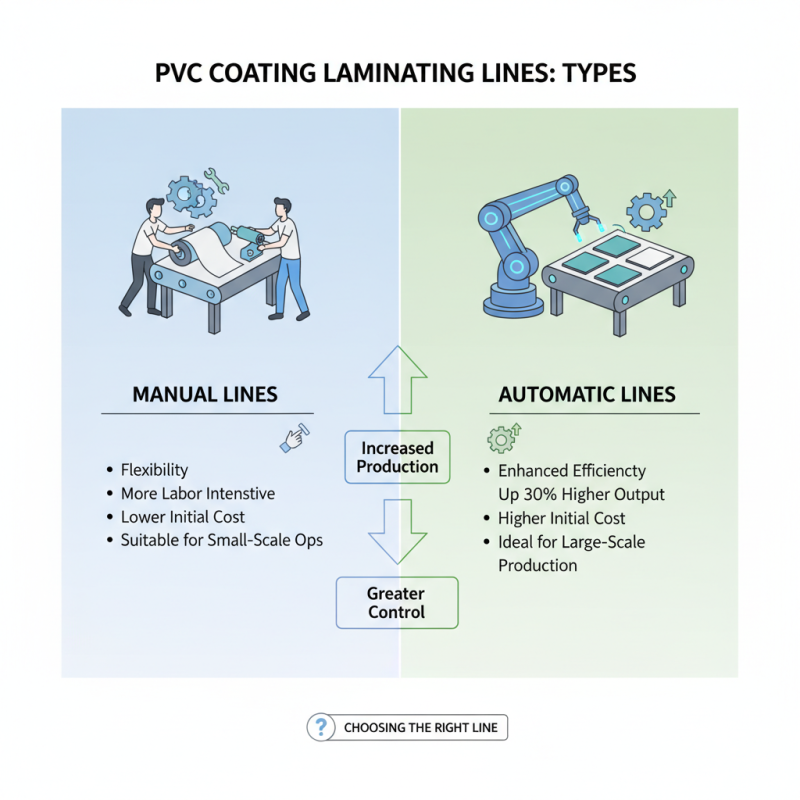

When selecting a PVC coating laminating line, understanding the types available is crucial. Typically, there are two main categories: manual and automatic lines. Manual lines offer flexibility but require more labor. Automatic lines enhance efficiency but come with a higher initial cost. According to industry reports, automated systems can increase production by up to 30%. However, they may not suit every small-scale operation.

Tips: Assess your production volume before choosing. If you produce in smaller batches, a manual line may save costs. For larger outputs, automation could prove beneficial over time.

Choosing the right fit also depends on the type of PVC you plan to coat. Different laminating processes apply varying adhesive techniques. If you're starting out, consider both surface quality and durability. Reports show that not all PVC coatings adhere well, leading to potential product failures. Ensure you test small batches before committing to larger orders.

Tips: Think about your long-term needs. Invest in equipment that offers adaptability to different projects. It can prevent frustrations down the line.

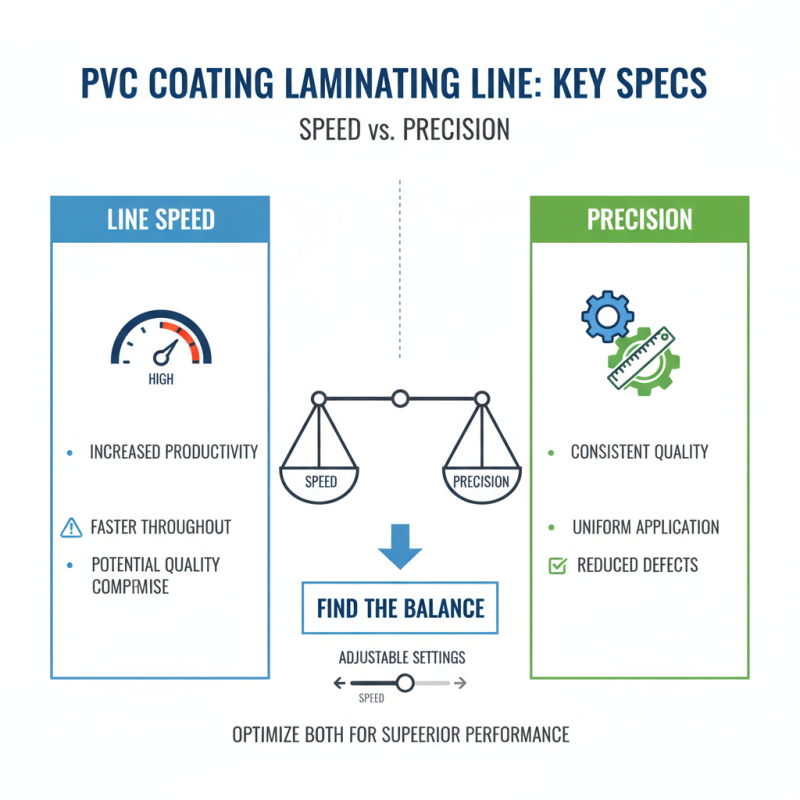

When choosing a PVC coating laminating line, technical specifications play a crucial role. A key factor is the speed of the line. Faster lines can increase productivity, but the quality must not suffer. It's important to consider the balance between speed and precision. Some machines may offer high speed but compromise on consistency. Look for adjustable settings to optimize both factors.

Another critical element is the heating method used in the laminating line. Hot air, infrared, or contact heating methods each have their pros and cons. Hot air units are efficient but may not penetrate thicker materials effectively. Infrared units provide even heating but can be less adaptable. Evaluate your material thickness and type before making a decision.

Material compatibility is often overlooked but vital. Not all lines are suitable for every type of PVC film or substrate. Failing to match these could result in defects. Moreover, consider maintenance requirements and ease of operation. A complex setup may lead to downtime. The best choice aligns with your specific needs and real-world conditions.

When considering a PVC coating laminating line, budgeting is key. Each system comes with different costs, from installation to maintenance. Decide on your budget early in the process. It helps narrow down your options. Some machines may appear cheaper but require more upkeep. Hidden costs can add up quickly.

Analyze your production needs. A high-capacity line may be tempting, but it can strain finances. Assess the volume and type of PVC products you plan to produce. If demand fluctuates, investing in a smaller line might be wise. Consider future growth but stay realistic about your current needs.

Don't overlook the potential for extra features. Automation can boost efficiency but increase the price. Weigh the benefits against the cost. A more complex line may not be the best choice for a startup. Reflect on the long-term implications of your investment. Choose wisely for sustainable growth.