Choosing the right Hot Melt Coating Machine is crucial for businesses looking to enhance their manufacturing processes and product quality. With a myriad of options available on the market, it can be overwhelming to determine which machine best suits your specific needs. This guide aims to provide valuable insights into the key considerations when selecting a Hot Melt Coating Machine, ensuring that your investment aligns with your operational requirements and goals.

Understanding the various features and capabilities of Hot Melt Coating Machines is essential in making an informed decision. Factors such as production volume, application type, and material compatibility play a significant role in selecting the most suitable machine. Additionally, assessing the machine's ease of use, maintenance requirements, and available support can further influence your choice. By focusing on these critical elements, you can identify a Hot Melt Coating Machine that not only meets your immediate demands but also supports your business's long-term growth and efficiency.

Hot melt coating machines play a crucial role in various manufacturing processes, primarily designed to apply a layer of adhesive or coating material onto substrates. These machines utilize thermoplastic materials that, when heated, transform into a liquid form, allowing for a uniform application across different surfaces. Upon cooling, the adhesive solidifies, forming a durable bond that withstands various environmental conditions. Understanding the basic functions of hot melt coating machines not only helps businesses enhance product quality but also streamlines their production workflows.

The core functionality of these machines involves precision heating and controlled application, which can significantly affect the performance of the coating. Most machines are equipped with advanced temperature control systems to ensure the adhesive reaches the optimal viscosity for effective application. Additionally, some machines offer adjustable speed and pressure settings, allowing them to meet diverse application needs across different industries, from packaging to textiles. By mastering the basics of these machines, business owners can better select the right equipment that aligns with their specific operational requirements, resulting in improved productivity and product consistency.

When selecting a hot melt coating machine, several key features should be taken into account to ensure it meets your business needs. First and foremost, consider the machine's output capacity, as this will directly impact your production efficiency. It is essential to evaluate the machine's application speed and consistency; a reliable machine should provide uniform coatings while maintaining rapid output to keep up with demand. Moreover, look for models that offer adjustable temperature controls and a variety of nozzle options, enabling flexibility for different coating materials and thicknesses.

Another important feature to assess is the machine's ease of use and maintenance. An intuitive control panel simplifies operation, allowing for quick adjustments and minimizing downtime. Additionally, machines that are designed for easy cleaning and have accessible parts can significantly reduce maintenance efforts. You should also take into account the machine's durability and build quality; a robust construction can withstand high-volume production environments. Lastly, consider the availability of technical support and training resources from the manufacturer, as this can greatly assist in maximizing the performance of your hot melt coating machine.

| Feature | Description | Importance |

|---|---|---|

| Coating Thickness Control | Ability to adjust coating thickness for different applications. | High |

| Application Speed | Rate at which the machine can apply coating. | Medium |

| Temperature Control | Precision in heating and maintaining molten adhesive. | High |

| Ease of Maintenance | Simplicity of access to components for cleaning and servicing. | Medium |

| Versatility | Ability to handle various substrates and coating materials. | High |

| Control Systems | Advanced control systems for automation and precision. | High |

| Energy Efficiency | How much energy the machine consumes during operation. | Medium |

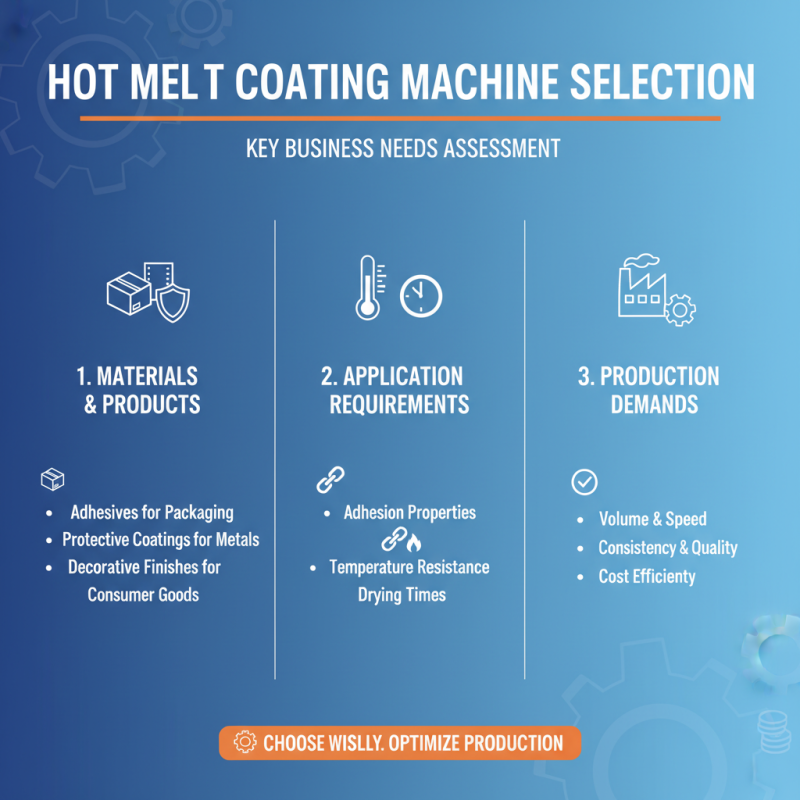

When evaluating your business needs for coating applications, it is essential to first assess the types of materials and products you are working with. Different industries require different coating solutions, such as adhesives for packaging, protective coatings for metals, or decorative finishes for consumer products. Understanding the specific requirements of your applications, such as adhesion properties, temperature resistance, and drying times, will help narrow down your options for hot melt coating machines. A thorough analysis of these factors will ensure you select a machine that can effectively meet your production demands.

Additionally, consider the scale of your operations and your production volume. Are your coating needs consistent or do they fluctuate seasonally? Identifying the throughput capabilities you require will guide you in choosing a machine that aligns with your operational efficiency goals. It is also important to think about ease of maintenance and support, as these can significantly impact your long-term productivity. By clearly defining your business needs, you can make informed decisions that will optimize your coating processes and enhance your overall manufacturing effectiveness.

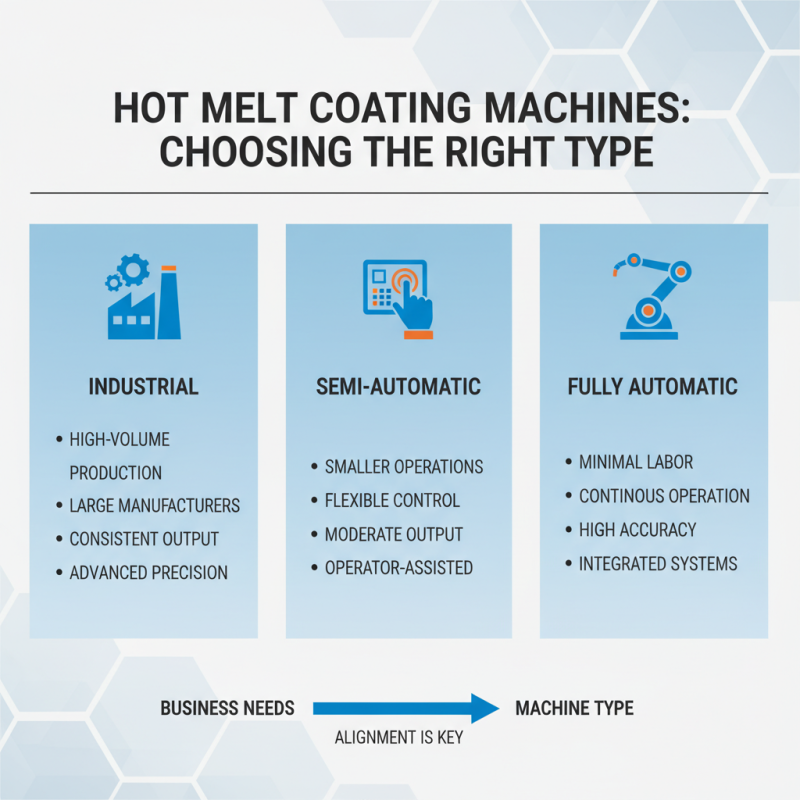

When selecting a hot melt coating machine, it's crucial to understand the different types available and how they align with your business needs. Hot melt coating machines can generally be categorized into industrial, semi-automatic, and fully automatic models. Industrial machines are designed for high-volume production, making them suitable for large manufacturers. They offer consistent output and advanced features for precision coating. On the other hand, semi-automatic machines provide flexibility for smaller operations, allowing operators to control various settings while still achieving a significant output.

Tips: Before making a decision, consider the scale of your operations and the specific applications you'll be using the machine for. Different types may have varying capabilities, such as speed, precision, and material compatibility. If your business requires versatility in coating different materials, a semi-automatic model might be more advantageous, as it can accommodate various applications.

Furthermore, evaluating the machine's technology is essential. Some hot melt coating machines deploy advanced methods like slot die coating, while others use roll coating techniques. Each method has its benefits and drawbacks depending on the intended outcome and materials. Conducting thorough research and assessing product specifications will help you choose a machine that meets your workflow and quality standards effectively.

When selecting a hot melt coating machine, budgeting and maintenance considerations play a crucial role in ensuring the longevity and efficiency of the equipment. The initial investment in a hot melt coating system can vary significantly; industry reports indicate that entry-level machines may start at approximately $10,000, while high-performance models can reach upwards of $50,000. Companies must evaluate their production needs and frequency of use to allocate an appropriate budget. Additionally, operational costs should be factored in, including energy consumption, adhesive materials, and labor associated with running the machine.

Maintenance is equally critical in maximizing the return on investment for hot melt coating machines. Regular maintenance tasks, such as cleaning, inspection of the adhesive application systems, and monitoring temperature controls, can help prevent costly breakdowns. According to a 2022 report from the Adhesive and Sealant Council, businesses that implement routine maintenance can extend the operational lifespan of their machinery by up to 30%. Furthermore, it is essential to train personnel on proper operational techniques to minimize wear and tear, ultimately reducing the frequency of repairs and replacements. Balancing these budgeting and maintenance considerations will empower businesses to choose the most suitable hot melt coating machine for their specific production needs.