In the rapidly evolving world of manufacturing, selecting the right Coating Lamination Machine is crucial for businesses that aim to enhance their product durability and visual appeal. According to industry expert Dr. James Whitman, a leading authority in coating technology, "The choice of a Coating Lamination Machine can significantly impact both production efficiency and product quality." His insights highlight the importance of making an informed decision based on specific operational needs.

When venturing into the selection process, businesses must evaluate various factors such as machine capabilities, production volume, and material compatibility. Each of these elements plays a vital role in how well the Coating Lamination Machine will perform in real-world applications. Understanding these requirements can help streamline operations and lead to better product outcomes, ultimately driving business growth and customer satisfaction.

Moreover, with advancements in technology, newer models of Coating Lamination Machines offer features that enhance precision and reduce waste, serving as a game-changer for modern manufacturers. As companies look to upgrade or invest in new equipment, they must consider not only current needs but also potential future demands to stay competitive in the market. Choosing wisely can pave the way for improved operational success and better product offerings.

Coating lamination machines serve a crucial role in various industries by providing a protective layer to products, enhancing both durability and aesthetics. These machines come in several types, each designed to meet specific needs. For instance, hot lamination machines utilize heat to bond layers together, making them ideal for applications requiring a tight seal and added strength.

Cold lamination machines, on the other hand, use pressure without heat, offering versatility for sensitive materials that may be damaged by high temperatures. Understanding these fundamental types is essential for selecting the right machine for your production requirements.

The functions of coating lamination machines extend beyond mere protection; they also improve the visual appeal of products. For example, glossy finishes can enhance color vibrancy, while matte coatings can lend a sophisticated touch to packaging. Some advanced machines are equipped with multiple rollers and adjustable settings, allowing operators to customize the thickness and type of lamination according to the material being processed.

Additionally, certain models feature built-in cutting mechanisms to streamline production by eliminating the need for separate finishing equipment. By understanding the different types and functions of coating lamination machines, businesses can make informed choices that align with their operational needs and product specifications.

When selecting a coating lamination machine, several key factors come into play that can significantly influence your decision. First, the type of materials you plan to process is critical. Different machines are designed to handle various substrates, such as paper, plastic, or metal. Therefore, assessing the compatibility of the machine with your materials ensures optimal performance and quality of the laminated product.

Another essential factor is the production volume and speed requirements. For businesses with high output demands, machines that offer quicker processing speeds and higher capacities are imperative. Additionally, flexibility in operations—such as the ability to accommodate various lamination thicknesses and finishes—can enhance productivity and adaptability to changing project needs. Finally, the ease of use and maintenance of the machine should not be overlooked, as user-friendly interfaces and straightforward servicing procedures contribute to efficient operation and lower downtime.

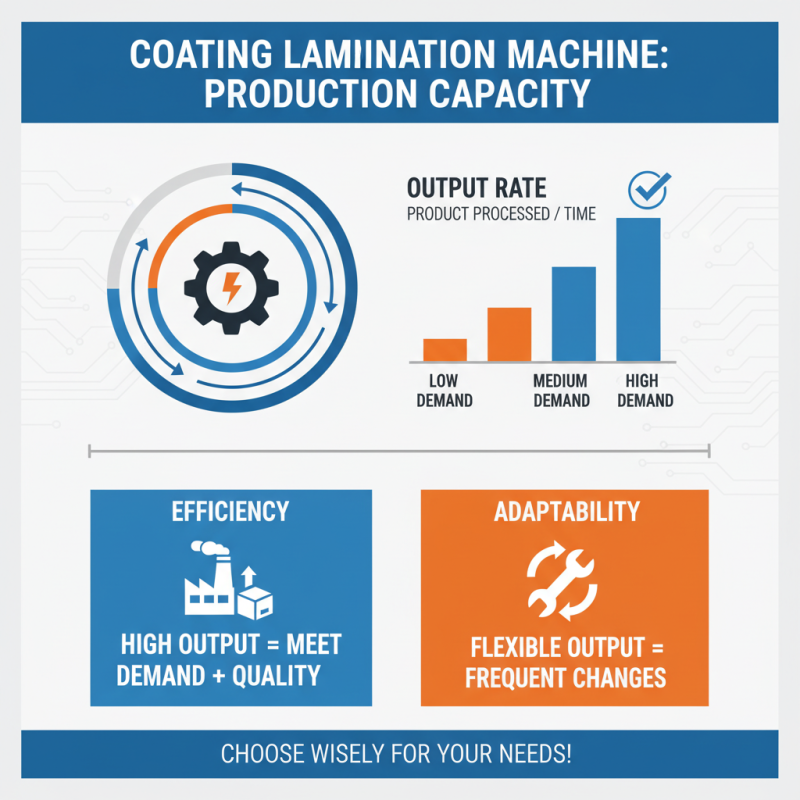

When selecting a coating lamination machine, evaluating production capacity is crucial. Output rates, or the amount of product processed per unit of time, provide a primary measure of a machine's efficiency. Ideally, a high output rate indicates that the machine can meet demands without compromising on quality. It is essential to consider your specific production needs; for instance, if your operation requires frequent changes in products or sizes, flexibility in output can significantly enhance overall efficiency.

Efficiency standards further refine your choice by assessing energy consumption, speed variability, and material waste during the lamination process. Machines that offer lower energy consumption while maintaining high output can lead to substantial cost savings over time. Additionally, understanding how a machine manages different substrates and adhesives can help in determining its overall suitability for your intended applications. Prioritizing both output rates and efficiency standards will ensure that you invest in a machine that not only meets your current production needs but also enhances your operational capabilities for the future.

When selecting a lamination machine, material compatibility is a critical factor that can influence the overall effectiveness and quality of the finished product. Different lamination materials, such as polyester, polypropylene, or vinyl, offer distinct advantages depending on the specific application. According to industry reports, over 60% of businesses that invest in lamination technology prioritize material compatibility as a key selection criterion, ensuring their machine can handle diverse substrates efficiently.

Understanding the properties of each type of lamination material is essential. For instance, polyester lamination is known for its durability and resistance to moisture, making it ideal for items that require long-term preservation, such as ID cards and menus. Meanwhile, polypropylene, with its lower melting point and ease of processing, suits applications where flexibility and surface finish are paramount. Industry analysts predict that as demand for customized packaging continues to rise, the lamination market will experience a 4.5% CAGR over the next five years, reflecting the importance of choosing the right laminating material for commercial success.

It is also vital to consider the thickness of the material you intend to laminate, as this can greatly affect the type of machine needed. Reports suggest that machines capable of handling thicker materials are increasingly in demand, with a projected increase in sales for robust models expected to rise by nearly 25% within the next year. Therefore, businesses must carefully align the specifications of their lamination machines with the materials they will primarily use to maximize production efficiency and product quality.

| Material Type | Recommended Coating Type | Thickness Range (mm) | Ideal Application |

|---|---|---|---|

| Paper | Thermal Lamination | 0.05 - 0.5 | Books, Magazines |

| Cardboard | Liquid Lamination | 0.8 - 2.5 | Packaging, Displays |

| Plastic | Cold Lamination | 0.1 - 1.0 | Banners, ID Cards |

| Vinyl | Pressure-Sensitive Lamination | 0.2 - 1.5 | Signage, Stickers |

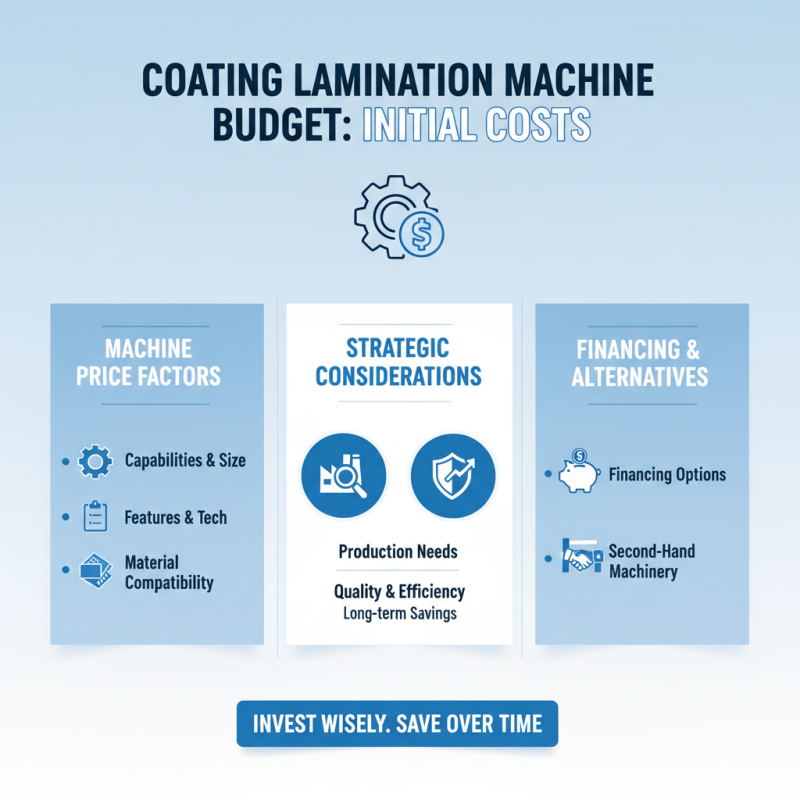

When budgeting for the purchase and maintenance of a coating lamination machine, understanding the initial costs is crucial. The price of the machinery can vary significantly based on its capabilities, size, and features. It's essential to consider your specific production needs and the materials you will be working with, as these factors will influence the type of machine you will require. Investing in a higher-quality lamination machine may lead to better efficiency and durability, ultimately saving costs over time. Additionally, evaluating potential financing options or second-hand machinery can ease the financial burden.

Maintenance costs are another critical aspect to consider when calculating your budget. Regular maintenance is vital to ensure optimal performance and longevity of the machine. This includes routine inspections, parts replacements, and servicing by professionals, which can add up over time. It's important to factor these costs into your overall budget. Furthermore, training your staff to operate and maintain the machine can help prevent costly errors and downtime, leading to a more efficient production process. Ensuring that you have a comprehensive understanding of both the initial purchase and ongoing maintenance expenses will help you make a well-informed decision tailored to your business needs.