The manufacturing industry is continually evolving, with advancements in technology playing a pivotal role in enhancing production efficiency and product quality. Among the revolutionary innovations, the Ud Impregnation Machine stands out as an essential tool for various industrial applications. According to market research reports, the global market for impregnation machines is projected to grow significantly, driven by the increasing demand for high-performance materials in sectors such as automotive, aerospace, and construction. This growth is largely attributed to the superior properties imparted to products treated with vacuum impregnation processes.

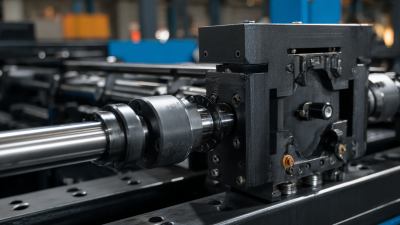

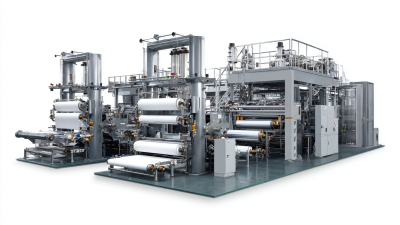

The Ud Impregnation Machine is designed to optimize the impregnation process, ensuring even distribution of resin and reducing production time while enhancing durability and performance of the end products. Industry analysts highlight that the adoption of advanced impregnation technology can increase the longevity and reliability of components, with studies showing that parts treated with Ud Impregnation Machines exhibit up to a 30% increase in lifespan compared to untreated materials. As industries seek to maintain competitive advantages, integrating such sophisticated machinery not only meets quality standards but also provides significant cost savings in the long run. The following sections will delve into the top ten benefits of utilizing Ud Impregnation Machines, demonstrating their crucial role in modern industrial applications.

Ud impregnation techniques have revolutionized material processing across various industrial applications by significantly enhancing material strength. These advanced methods improve the density and structural integrity of materials, allowing them to withstand higher stress and load conditions. The impregnation process, which involves filling the porous spaces within materials with a resin or adhesive, not only fills voids but also binds fibers more effectively. This leads to composites that exhibit superior strength, durability, and resistance to wear and tear.

Moreover, the enhanced strength achieved through Ud impregnation techniques directly translates to improved performance in demanding environments. Industries such as aerospace, automotive, and construction benefit from components that can endure extreme conditions without compromising safety or functionality. With the ability to customize the impregnation process for specific material types and application needs, manufacturers can create tailored solutions that maximize efficiency and longevity, positioning their products to outperform traditional materials under similar conditions. This not only reduces the frequency of repairs and replacements but also contributes to more sustainable industrial practices.

| Benefit | Description | Impact on Material Strength |

|---|---|---|

| Increased Durability | Ud impregnation improves the overall durability of materials against wear and tear. | Extends lifespan of components. |

| Enhanced Corrosion Resistance | Protects materials against corrosive environments and fluids. | Reduces deterioration rate. |

| Improved Mechanical Strength | Increases tensile strength and fracture toughness. | Allows for the use of lighter materials without compromising strength. |

| Reduced Porosity | Fills voids and gaps in materials, resulting in denser components. | Enhances load-bearing capacity. |

| Thermal Stability | Improves performance in high-temperature applications. | Increases resistance to thermal degradation. |

| Cost Efficiency | Reduces maintenance costs and extends intervals between replacements. | Contributes to overall operational savings. |

| Enhanced Performance | Optimizes the performance of components under load. | Prevents premature material failure. |

| Versatility | Can be applied to various materials including metals and composites. | Broadens application possibilities. |

| Environmentally Friendly | Utilizes sustainable practices and materials. | Minimizes environmental impact. |

| Innovation | Incorporates advanced technologies leading to better results. | Keeps pace with evolving industry standards. |

The reduction in porosity levels is a significant benefit of using Ud impregnation machines, particularly in industrial applications. Porosity can lead to weakness in materials, allowing for the degradation of product integrity over time. By employing impregnation techniques, manufacturers can effectively fill voids and micro-cracks within materials, resulting in a denser, more uniform structure. This minimizes the likelihood of faults developing during operation, thus enhancing the overall performance of the product.

Moreover, the improvement in product lifespan directly correlates with decreased porosity. In many industrial applications, components are subject to various stresses and environmental factors that can exacerbate any existing porosity issues. Ud impregnation machines ensure that materials are treated to resist corrosion, chemical damage, and thermal shocks, significantly extending their usable life. As a result, industries can benefit from reduced maintenance costs and fewer replacements, leading to substantial savings over time. This makes investing in impregnation technology a strategic decision for manufacturers aiming to enhance product quality and durability.

In today's competitive manufacturing landscape, the cost efficiency of processes plays a crucial role in the success of industrial applications. Ud impregnation machines have emerged as a game-changer, significantly reducing production time and associated costs. According to a recent report by Smith Industries, companies that implemented Ud impregnation machines reported a 30% decrease in production time, allowing for a quicker turnaround on orders and enhanced responsiveness to market demands.

The rapid production times enabled by Ud impregnation technology not only streamline manufacturing processes but also lead to a substantial reduction in labor costs. With the increased efficiency, companies are able to minimize downtime and waste. For instance, a study conducted by the Industrial Efficiency Association found that manufacturers utilizing these machines realized savings of up to 20% in labor expenses. This cost efficiency enables firms to allocate resources more effectively, ultimately boosting their overall profitability and competitiveness within the industry.

Furthermore, the integration of Ud impregnation machines allows for higher output without compromising on quality, vital in today’s demand-heavy environment. As companies look to improve their production capabilities, these machines present a clear path to achieving substantial cost efficiencies that can drive long-term growth and sustainability.

The use of Ud impregnation machines in industrial applications brings significant environmental benefits, particularly in terms of reducing chemical waste and emissions. According to a report by the Environmental Protection Agency (EPA), industrial processes account for nearly 50% of total chemical waste generated in the United States. By adopting advanced impregnation technologies, companies can achieve a notable reduction in chemical usage—by as much as 30%—which directly translates to decreased waste production.

Furthermore, emissions related to solvent use can significantly impact air quality and contribute to greenhouse gas accumulation. The implementation of Ud impregnation machines allows industries to utilize more sustainable materials and processes. A study by the International Journal of Industrial Engineering highlighted that such technologies can reduce volatile organic compound (VOC) emissions by 40%, leading to a healthier workplace and a reduced environmental footprint. This not only helps in compliance with stringent regulations but also enhances the overall sustainability profile of manufacturing operations, positioning businesses as leaders in environmental responsibility.

Ud impregnation machines have gained prominence across a range of industries, particularly in aerospace and automotive applications. Their versatility allows for the efficient impregnation of porous materials, ensuring superior performance and longevity. In aerospace, for example, these machines enhance the durability of composite materials used in aircraft, leading to increased safety and reliability. Similarly, in the automotive sector, Ud impregnation machines improve the structural integrity of components, enabling manufacturers to meet stringent safety standards while optimizing material use.

When considering the implementation of Ud impregnation machines, it is essential to assess your specific operational needs. Tip: Ensure to evaluate the compatibility of impregnation materials with existing production processes to achieve seamless integration. Moreover, training personnel in the optimal use of these machines can significantly affect outcome quality. Tip: Invest in regular training sessions to keep your team updated on the latest techniques and maintenance practices. By leveraging these machines and focusing on continuous improvement, industries can enjoy enhanced product performance and significant cost savings over time.