The Swing Arm Cutting Press has emerged as a game-changer in the realm of material handling and processing, enhancing efficiency and precision across various industries. According to recent industry reports, the global market for cutting machinery is projected to reach $12 billion by 2025, driven by innovations in equipment design and increased demand for automated solutions. The Swing Arm Cutting Press stands out due to its unique design that optimizes operator ergonomics and minimizes material wastage. By enabling quick adjustments and precise cuts, this equipment not only streamlines production but also significantly reduces operational costs. As manufacturers continue to seek out ways to increase productivity while maintaining high-quality standards, understanding the benefits of the Swing Arm Cutting Press becomes essential for staying competitive in today's fast-paced market.

The garment industry is undergoing significant transformations as automation and advanced technologies reshape traditional processes. One crucial tool in this evolution is the swing arm cutting press, which plays a vital role in streamlining material handling. The design of the swing arm allows for greater precision and control, enabling manufacturers to cut fabric with exceptional accuracy. This precision not only minimizes waste but also enhances the quality of the finished products.

Moreover, the swing arm cutting press facilitates faster production cycles. By automating the cutting process, it reduces the time spent on manual cutting, allowing workers to focus on other critical tasks within the manufacturing workflow. This efficiency translates to quicker turnaround times, which is essential in meeting the demands of a rapidly changing market. As the garment industry embraces these technological advancements, the adoption of swing arm cutting presses will undoubtedly play a crucial role in improving productivity and maintaining competitive advantage.

The swing arm cutting press is revolutionizing the way material is cut and handled in various industries. By leveraging its advanced features, this tool enhances precision significantly during the cutting process. The unique design allows for easy maneuverability, ensuring that cuts are not only accurate but also efficiently completed. This level of precision reduces material waste and ensures that each piece meets the required specifications, which is particularly beneficial in fields like garment manufacturing and crafting.

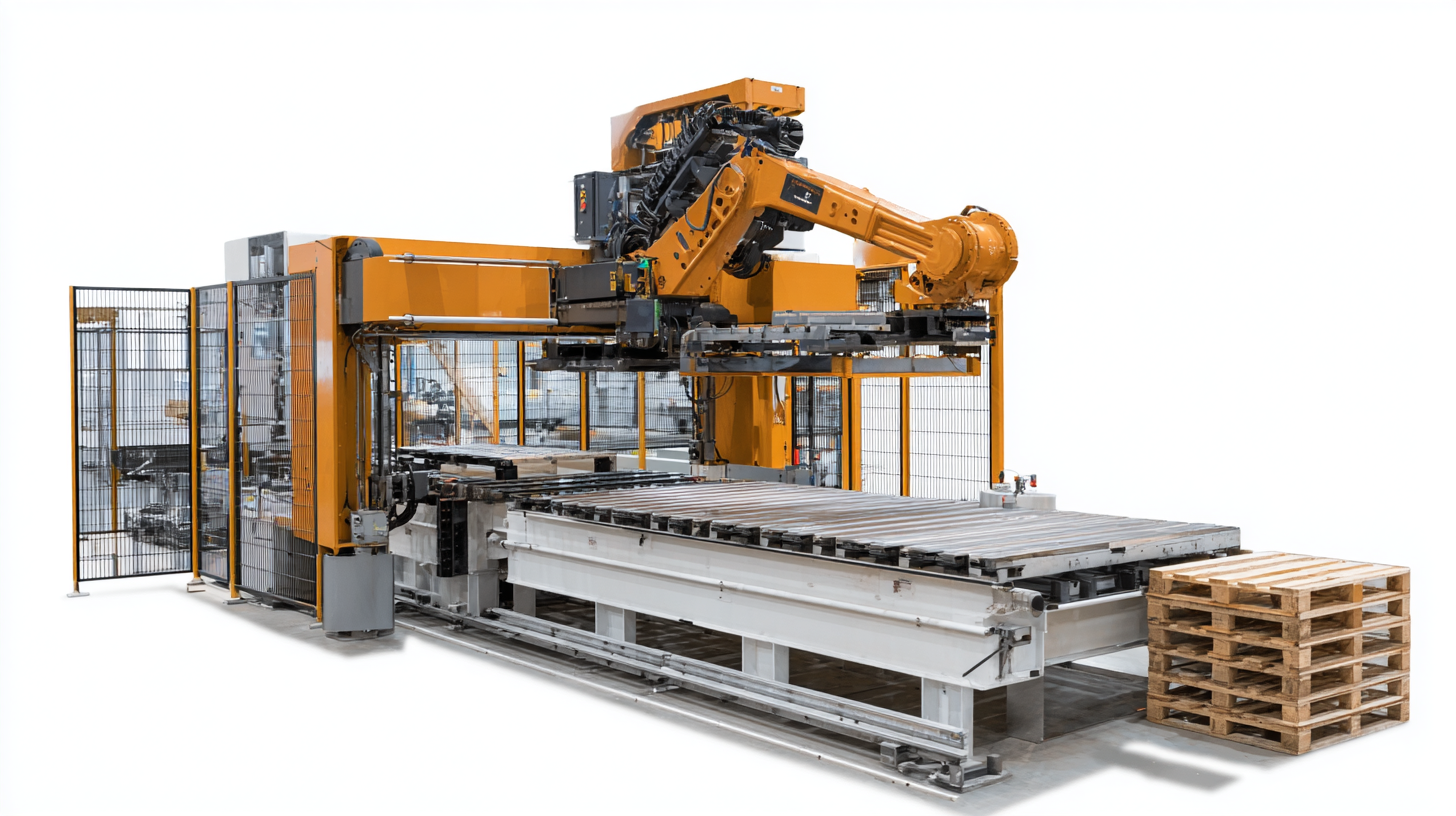

Furthermore, the integration of automated systems in swing arm cutting presses has further elevated their capabilities. These advancements allow for consistent performance, maintaining quality across all cuts, regardless of the workload. As industries adapt to modern automation trends, the swing arm cutting press stands out as a reliable solution that not only improves efficiency but also meets the increasing demands for accuracy in material handling. This transformative tool is paving the way for a more streamlined production process, reflecting the broader shifts observed in today's automated environments.

The swing arm cutting press is a game-changer for the garment industry, especially in terms of cost-effectiveness. As manufacturers strive to reduce waste and labor expenses, this technology offers a practical solution. By streamlining the cutting process, the swing arm design minimizes fabric loss, allowing for more efficient use of materials. This not only lowers costs but also enhances productivity, making it easier for businesses to adapt to the fast-paced demands of the market.

Tips for optimizing the use of a swing arm cutting press include proper training for operators to ensure they understand the machine's capabilities fully. Regular maintenance is crucial to keep the equipment in optimal condition, leading to consistent performance and reliability. Additionally, integrating automated systems with the cutting press can further enhance efficiency, aligning with the broader trend of advancements in automation and artificial intelligence in the garment industry. By maximizing these elements, businesses can maintain a competitive edge and better meet consumer demands.

This chart illustrates the estimated benefits of using a Swing Arm Cutting Press in material handling, showing significant potential savings and efficiency improvements across various operational dimensions.

The implementation of swing arm cutting presses has shown remarkable productivity gains in various industries. Recent industry statistics indicate that businesses utilizing this equipment have experienced an average increase in efficiency by up to 30%. This improvement can be attributed to the precise cutting process and the enhanced speed at which materials are handled, allowing manufacturers to streamline their operations and achieve higher output levels.

Moreover, companies that have adopted swing arm cutting presses report a significant reduction in material waste, with some studies suggesting reductions of approximately 20%. This is primarily due to the accurate cutting capabilities of these machines, which ensure minimal errors in material handling. As a result, not only do businesses benefit from increased productivity, but they also enjoy cost savings associated with decreased waste and enhanced operational efficiency. The transition to swing arm technology represents a forward-thinking step in modern manufacturing practices.

| Industry Sector | Average Productivity Gain (%) | Reduction in Material Waste (%) | Time Saved per Job (minutes) | Return on Investment (ROI) (%) |

|---|---|---|---|---|

| Apparel Manufacturing | 25 | 15 | 10 | 150 |

| Furniture Production | 30 | 20 | 15 | 180 |

| Automotive Parts | 20 | 10 | 8 | 120 |

| Leather Goods | 28 | 12 | 9 | 160 |

| Textile Industry | 22 | 18 | 11 | 140 |

The comparative analysis of swing arm cutting presses versus traditional cutting methods reveals substantial advantages in material handling. According to industry reports, swing arm cutting presses enhance processing speed by up to 40% compared to conventional methods. This increased efficiency not only shortens production cycles but also reduces labor costs, as fewer operators are required to achieve higher output levels. Additionally, the precision of swing arm presses allows for minimized waste, further optimizing material usage and operational costs.

Recent studies underline the significance of innovative technologies in cutting aggregate materials, paralleling advancements seen in tunneling machinery. For instance, the integration of active vibration cutting systems demonstrates improved performance in challenging conditions, such as deep mining. Employing cutting-edge rock-breaking technologies complements the advantages provided by swing arm cutting presses, which adeptly handle various materials with unmatched efficiency. As industries continue to evolve, the shift toward these advanced systems is likely to redefine best practices in material handling and overall production capabilities.