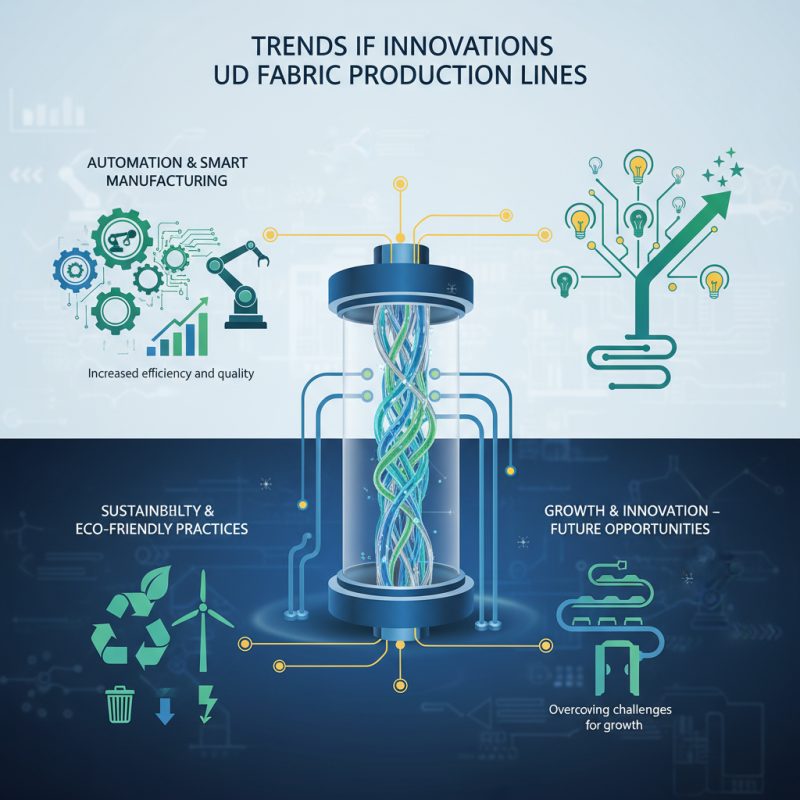

As the demand for high-performance materials increases, the Ud Fabric Production Line is evolving rapidly. Innovations in this sector are not only about efficiency but also sustainability. Manufacturers are experimenting with new technologies, aiming to enhance production capabilities.

In 2026, we expect to see notable trends shaping this industry. Automation and smart manufacturing techniques are gaining traction. These developments could improve output and quality. However, challenges remain. Companies must adapt their existing systems to integrate these advancements seamlessly.

Moreover, a focus on eco-friendly practices is emerging. Brands are pressured to reduce waste and energy consumption. While some are leading this change, others struggle to keep up. This discrepancy highlights the need for continuous improvement within the Ud Fabric Production Line. The path forward is fraught with obstacles but offers exciting opportunities for growth and innovation.

Sustainable practices are reshaping the landscape of Ud fabric production lines. Manufacturers are increasingly aware of their environmental impact. Innovations in this sector focus on eco-friendly materials and processes. The emergence of recycling and upcycling methods is notable. Many industries are seeking ways to reduce waste and energy consumption.

Tips for adopting sustainable practices include evaluating raw materials. Consider using organic fibers or recycled textiles. This approach not only reduces environmental harm but can also enhance brand reputation. Implementing energy-efficient technologies is another crucial step. It's essential to regularly assess production lines for efficiency.

However, challenges remain. Some manufacturers hesitate to make the switch due to costs. They worry about potential losses during the transition. Ensuring employee training on new practices is vital too. Workers need to adapt to these innovations to succeed. Embracing change takes time, but fostering a culture of sustainability can lead to significant long-term benefits.

The integration of smart technology into fabric manufacturing processes is reshaping the industry. According to a recent report by the International Textile Manufacturers Federation, smart textiles are projected to reach a market value of $3.7 billion by 2026. This significant growth highlights an increasing interest in automating and optimizing production techniques.

Utilizing IoT sensors, manufacturers can monitor processes in real time. This allows for quick adjustments and reduces waste. However, the implementation of smart systems isn't always smooth. Companies face challenges in training staff and managing data overload. Even with advanced technology, the human element remains critical.

Furthermore, data analytics enable predictive maintenance of machines. This can reduce downtime by up to 20%. Yet, many companies struggle to capture actionable insights from their data. A mismatch between technology and human expertise often leads to inefficiencies. As the industry moves forward, finding a balance between innovation and practical application is essential.

In recent years, the demand for eco-friendly materials in Ud fabric production has surged. Manufacturers are increasingly exploring sustainable options. Natural fibers like organic cotton and hemp are becoming popular choices. These alternatives not only reduce environmental impact but also enhance the fabric's comfort and breathability.

The push for innovation is evident in the creation of bio-based materials. Researchers are developing fabrics derived from renewable resources such as algae and corn. This trend highlights a growing awareness of ecological footprints. However, the transition to these materials is not without challenges. There are still issues related to scalability and cost-effectiveness that need addressing.

To truly embrace sustainability, the industry must focus on better production processes. Many factories still rely on outdated techniques that waste resources. Improving energy efficiency and reducing water use is essential. It's a complex journey, but a necessary one for the future of Ud fabric production. The shift to eco-friendly materials is promising but requires ongoing commitment and innovation.

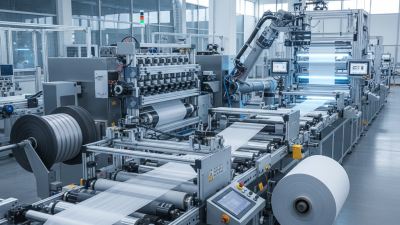

Automation is transforming the UD fabric manufacturing landscape. In recent years, companies have increasingly adopted advanced robotics and AI technologies. This shift aims to improve efficiency and reduce labor costs. For example, a report from the International Textile Manufacturing Association reveals that automation can increase production speed by up to 50%. This data highlights the positive impact of automation on manufacturing processes.

However, the transition to automation is not without challenges. Many manufacturers struggle with data integration between new robotic systems and existing processes. Additionally, workforce retraining can be costly and time-consuming. A survey by the Global Fabric Producers Association found that 30% of companies report difficulties in upskilling their employees for automated tasks. This aspect underscores the need for strategic planning in adopting automation technologies.

Moreover, the trend towards automation might lead to future skill gaps. As machines take over repetitive tasks, workers may find it difficult to adapt. Enhanced training programs are essential to address these challenges. Companies must ensure their workforce can thrive alongside new technologies. Despite the hurdles, the benefits of automation in improving operational efficiency are substantial. The industry must reflect on both the opportunities and the potential pitfalls of this evolution.

Innovative design techniques are reshaping the future of UD fabrics. As designers explore new methods, the focus is on sustainability and functionality. Many techniques use recycled materials, minimizing waste. This approach not only supports the environment but also meets consumer demands for eco-friendly products.

3D knitting is gaining popularity. It allows for complex designs without extra fabric waste. Designers create unique textures and patterns through this technique. While it offers opportunities, it also presents challenges. Precision in machinery is crucial, and errors can lead to significant material loss. Finding the right balance is vital for success.

Another trend is smart fabrics. These materials can adapt based on environmental conditions. For example, some can change color or temperature in response to light and heat. However, developing these fabrics requires extensive research and testing. The path to widespread use is still uncertain, as technological hurdles remain. Reflecting on these innovations, we see both potential and obstacles in fabric production.

| Trend/Innovation | Description | Impact on Production | Sustainability Aspect |

|---|---|---|---|

| Automated Weaving Technology | Integration of AI and robotics in the weaving process to enhance efficiency. | Reduces production time and increases output quality. | Lower energy consumption compared to traditional methods. |

| Smart Fabric Technology | Development of fabrics with integrated sensors for real-time monitoring. | Enhances product functionality while maintaining fabric comfort. | Promotes reduced waste through better usage tracking. |

| Circular Economy Practices | Focus on recycling materials and using biodegradable options. | Helps in reducing raw material costs and environmental footprint. | Significantly enhances sustainability efforts in fabric production. |

| Advanced Dyeing Techniques | Utilization of waterless dyeing methods and non-toxic dyes. | Accelerates dyeing process and minimizes resource usage. | Reduces wastewater generation significantly. |

| Blockchain for Transparency | Implementation of blockchain for tracking supply chain transparency. | Enhances trust and credibility in fabric sourcing and production. | Encourages ethical sourcing through accountability measures. |