Automatic UD Tape Crossply Machine description

Kuntai Group

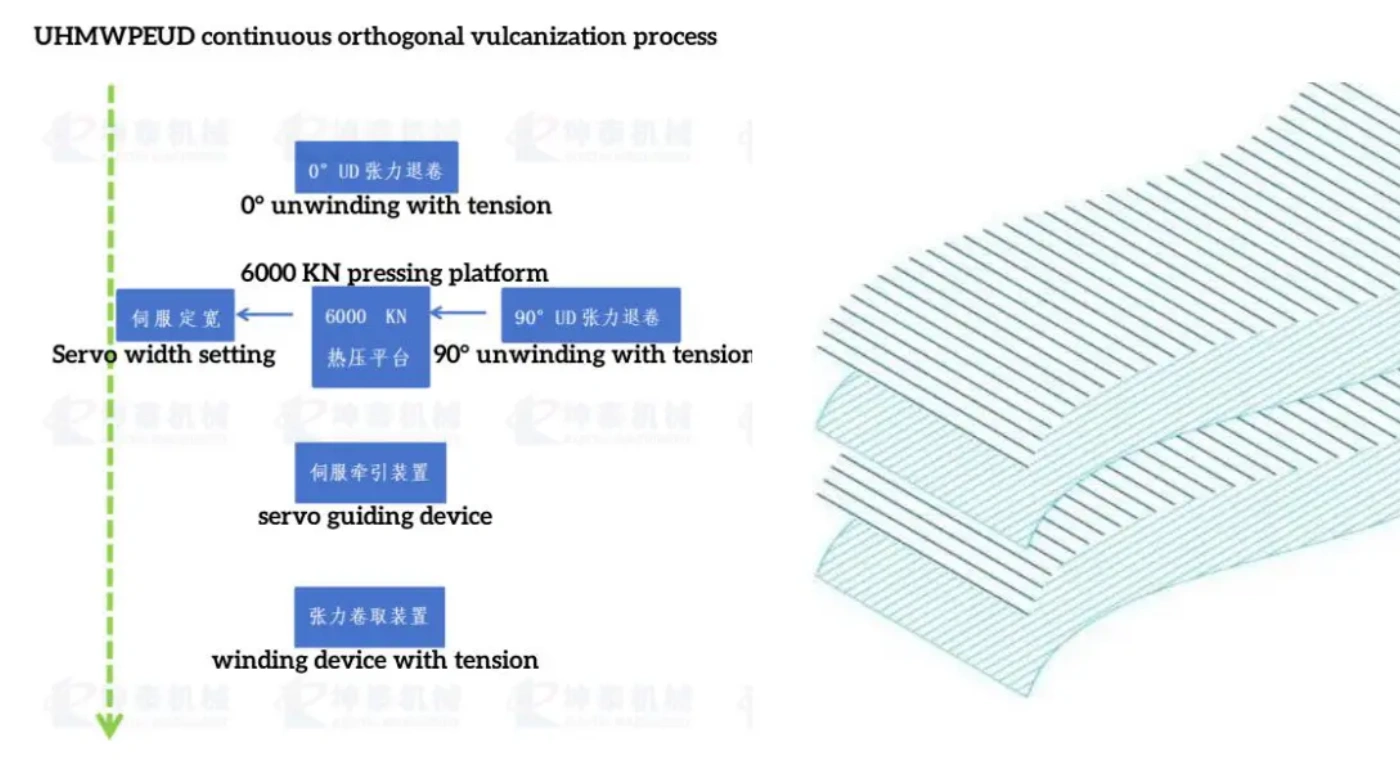

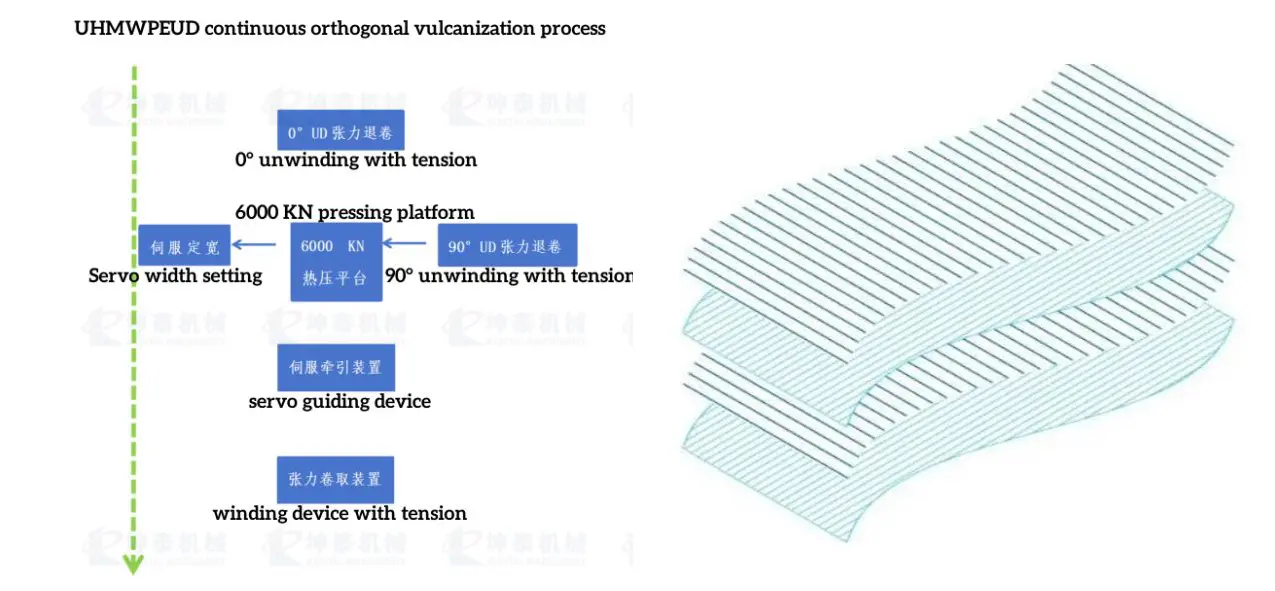

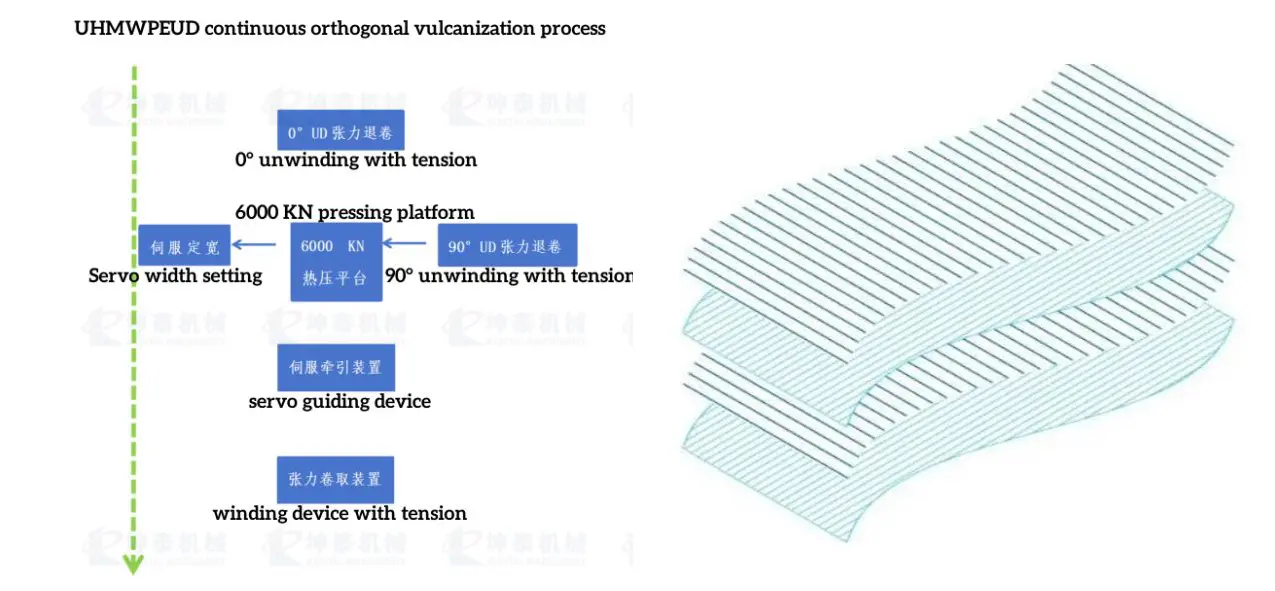

There are many types of machines which can orthogonally laminate 0 degree and 90 degree UD fabrics together. While as more and more people like automatic and labor saving methods, the Automatic UD Tape Crossply Machine is becoming more and more popular. This type of crossply machine can unwind 0 degree and 90 degree UD fabrics with proper tension, cut 90 degree UD fabrics into sheets and press and laminate 0 degree and 90 degree UD fabrics in one pass.

Kuntai UD Tape Crossply Machine is one kind of laminating machine which laminates UD fabrics or other materials feeding in two directions. It is widely used in 2UD/4UD/6UD production process and also other processes involving pressing and laminating of materials feeding in 0 degree and 90 degree.

If your 90 degree UD fabrics are already cut in sheets, you can use this UD tape crossply machine manually in feeding the 90 degree UD fabric sheets. It is versatile and can be adapted to your own UD fabric processing process, either for soft products or for hard products.

Automatic UD Tape Crossply Machine configuration

Kuntai Group

1.Structural summary

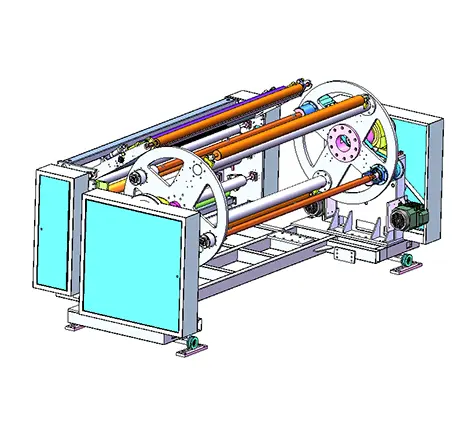

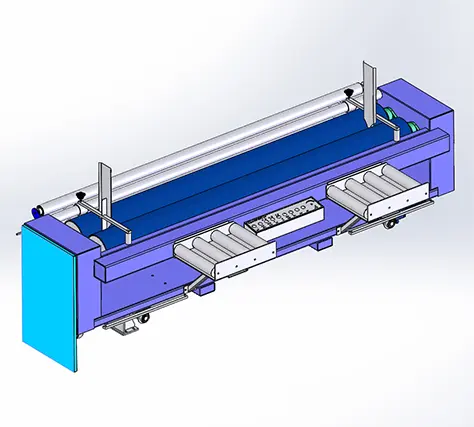

1) This type of UD Tape Crossply Machine consists of a tension unwinding frame, hydraulic device, thermal conductivity device, servo drive, linear transmission device, and traction winding;

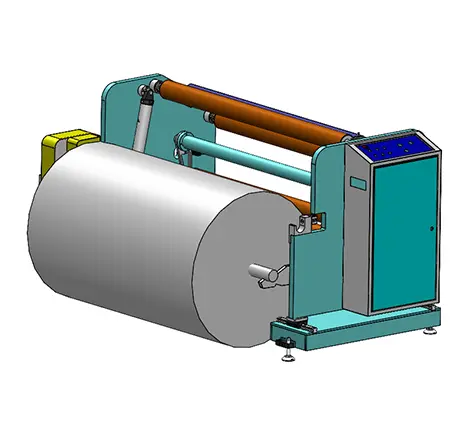

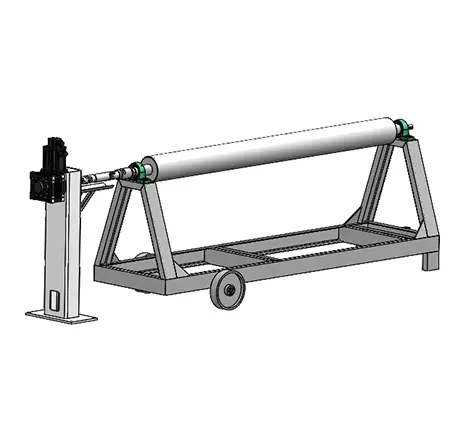

2) 0° UD 3-axis tension reel, capable of carrying 3 rolls of UD material for tension unwinding;

3) 90° UD fabric feeding device with tension control and sheet cutting device.

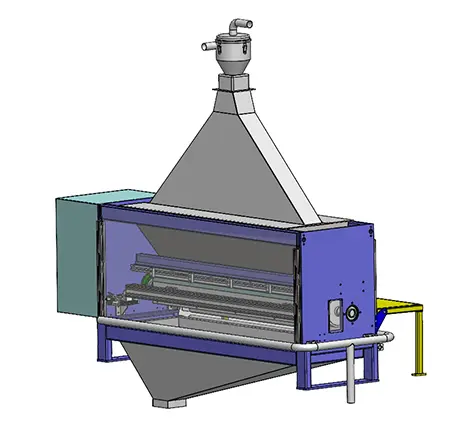

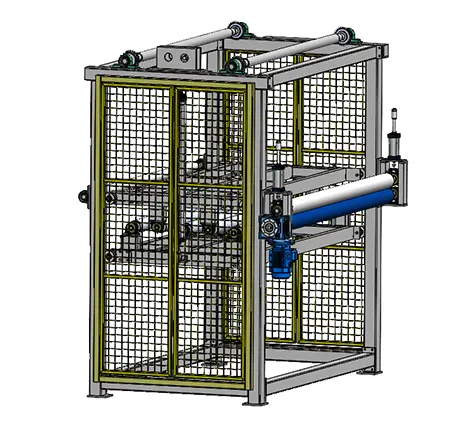

2.Pressing part

1)The 6000KN four cylinder hydraulic power acts on the 1700 * 1700mm lamination crossply tabletop, combined with HMI+PLC to control pressure, acceleration, pressure holding and other functions.

2)The heat source medium required for the UD Tape Crossply Machine is thermal oil, equipped with a dual external circulating mold oil heater.

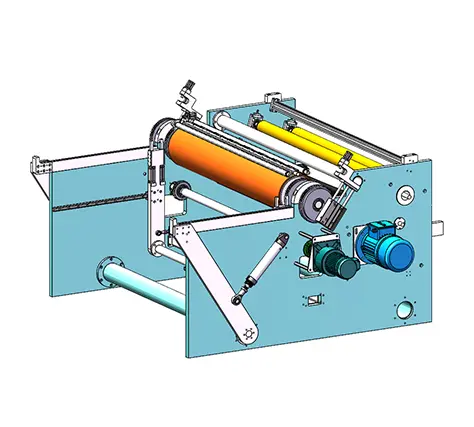

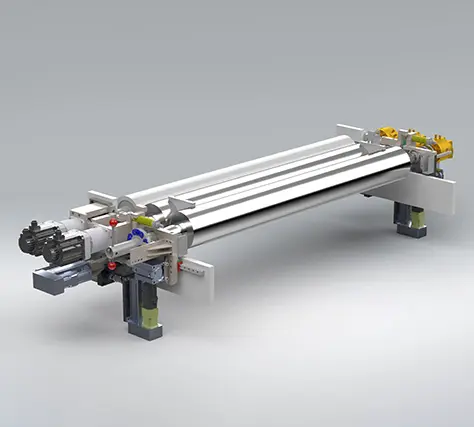

3.Guiding and winding

The laminated product is pulled by servo rollers to achieve longitudinal specification improvement each time, and combined with tension coiling to achieve UD composite product winding.

4.Electrical part

1).The main control cabinet of this type of UD Tape Crossply Machine is installed on the middle right side of the machine (to be determined by the purchaser on site);

2).The on-site installation materials and construction of the equipment to the electrical cabinet shall be completed by the purchaser, and the servo motor encoder signal line shall be provided by the supplier;

3).The control mode of the AC motor is circuit breaker+contactor+thermal protector+motor;

4). All outputs of PLC are controlled by intermediate relays to execute components;

5). All accessory circuits are protected by circuit breakers or fuses;

6). The architecture of the electrical control system adopts the "HMI+PLC" structure. Various information of equipment and electrical control components, such as operation, operating status, errors, auxiliary contacts, protection relay contacts, limits, safety protection switches, etc., are connected to the PLC, and all control logic and process calculations are completed by the PLC.

1) This type of UD Tape Crossply Machine consists of a tension unwinding frame, hydraulic device, thermal conductivity device, servo drive, linear transmission device, and traction winding;

2) 0° UD 3-axis tension reel, capable of carrying 3 rolls of UD material for tension unwinding;

3) 90° UD fabric feeding device with tension control and sheet cutting device.

2.Pressing part

1)The 6000KN four cylinder hydraulic power acts on the 1700 * 1700mm lamination crossply tabletop, combined with HMI+PLC to control pressure, acceleration, pressure holding and other functions.

2)The heat source medium required for the UD Tape Crossply Machine is thermal oil, equipped with a dual external circulating mold oil heater.

3.Guiding and winding

The laminated product is pulled by servo rollers to achieve longitudinal specification improvement each time, and combined with tension coiling to achieve UD composite product winding.

4.Electrical part

1).The main control cabinet of this type of UD Tape Crossply Machine is installed on the middle right side of the machine (to be determined by the purchaser on site);

2).The on-site installation materials and construction of the equipment to the electrical cabinet shall be completed by the purchaser, and the servo motor encoder signal line shall be provided by the supplier;

3).The control mode of the AC motor is circuit breaker+contactor+thermal protector+motor;

4). All outputs of PLC are controlled by intermediate relays to execute components;

5). All accessory circuits are protected by circuit breakers or fuses;

6). The architecture of the electrical control system adopts the "HMI+PLC" structure. Various information of equipment and electrical control components, such as operation, operating status, errors, auxiliary contacts, protection relay contacts, limits, safety protection switches, etc., are connected to the PLC, and all control logic and process calculations are completed by the PLC.

AccessoriesOption

01020304050607080910

automatic ud tape crossply Machine Features

Kuntai Group

1. The UD Tape Crossply Machine uses PLC control and touch screen operation. Feeding distance, pressing time, etc can be input and adjusted easily by the operator. It is user friendly.

2. Servo motor drives the feeding and pulling process, which makes the UD Tape Crossply Machine precise and highly efficient.

3. Unwinding with magnetic powder brake and rewinding with magnetic powder clutch, providing proper tension in the whole crossply process.

4. Unwinding and rewinding all use safety stirrup, which ensures operation safety.

5. Kuntai unique oil cylinder design and pressure system guarantee stable operation throughout the whole crossply procedures.

6. External oil boiler provides suitable heating for the pressing laminating process of the UD Tape crossplying.

7. High frequency quenching and hard chromium plating treatment are carried out on the surface of the moving track to ensure nondeformation during the long service life of the UD Tape crossply machine.

automatic ud tape crossply machine Technical Parameters (Customizable)

Kuntai Group

| Machine table size | 1700x1700mm |

| Max material width | 1650mm |

| Max pressing force | 600ton, 800ton, customizable |

| Control mode | HMI+PLC |

| Drive control | Servo motor |

| Heat source mode | Oil heater |

| Temperature control method | Module |

| Pressing method | Hydraulic |

| Total power | 110kw |

| PLC Brand | Mitsubishi |

| Servo Motor Brand | Mitsubishi |

| Electrical Parts Brand | Schneider/Omron |

| Temperature Control Brand | Fuji |

automatic ud tape crossply machine Application

Kuntai Group

Application and Usage of UD Prepregs

- Space and Air craft (aerospace) structure and parts

- Blades for wind turbines

- Automotive parts and components

- Recreational sports equipment

- Industrial structure and parts

- Military (2UD/4UD/6UD/8UD)

- Civil and Building Reinforcement

Packaging And Shipping

Kuntai Group

Automatic UD Tape Crossply Machine Inner Package: Protective Film, Plywood Case, etc .

Automatic UD Tape Crossply Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: 008615862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88