AccessoriesOption

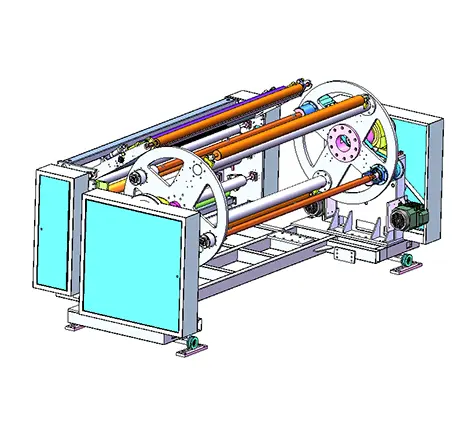

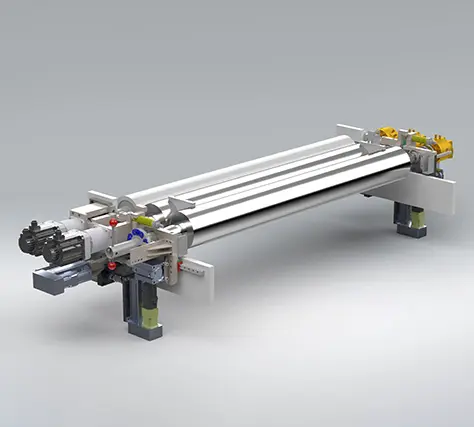

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

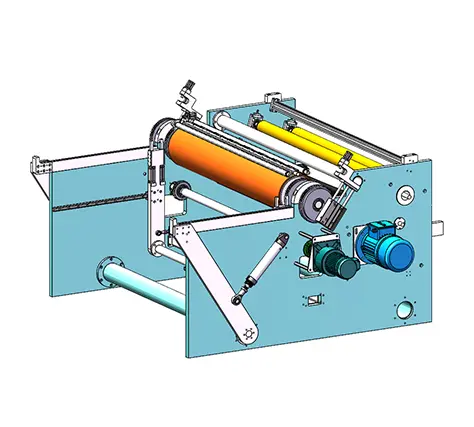

| Gap Adjustment | Servo Motor Control |

| Heating Method | Oil Heater |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 42-60kw, Customizable |

| Voltage | 220v, 380v, Customizable |

| Control system | Touch screen, PLC, servo motor |

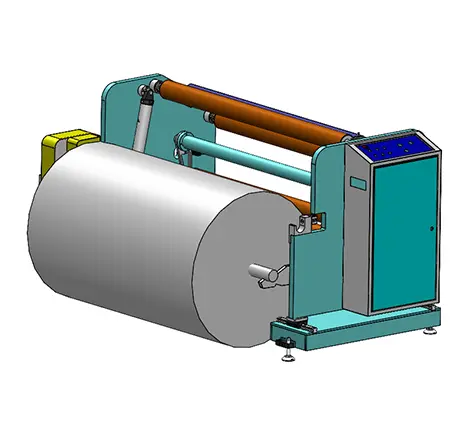

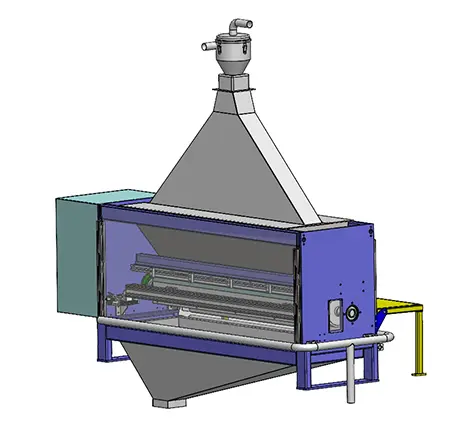

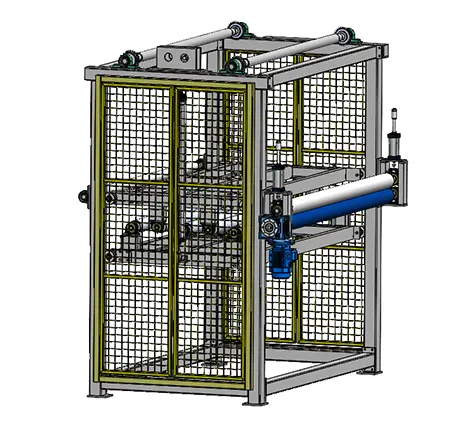

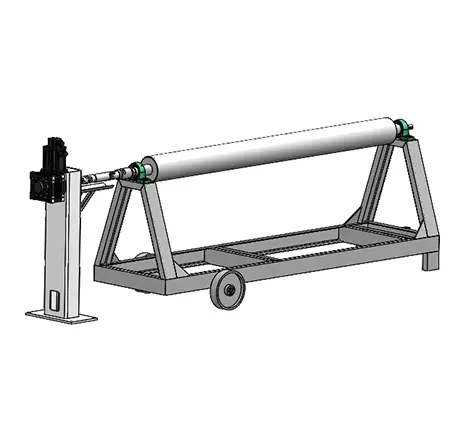

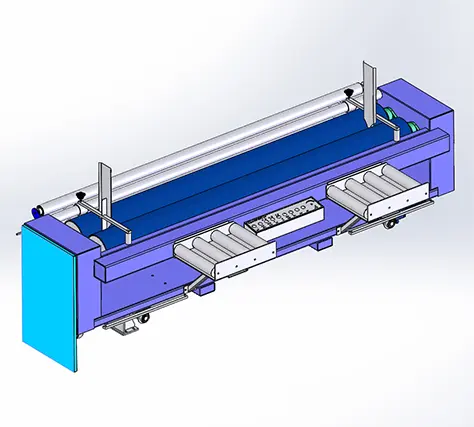

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

2)Tell us pls what are the raw materials you want to laminate together? Velvet, fleece, film, EVA, leather, sponge, nonwoven or other?

3)Tell us your raw materials max width. Materials in rolls or in sheets?

4)Tell us about your special or customized requirements for the laminating machine.

With cooperation with world’s leading technological German and Italian engineers and over 40 years experience, Kuntai develops new technology in both laminating machines and cutting machines every year, providing solutions to wordwide machine users and enhancing good long term relationship with old customers.

Excellent Machining Centers and Equipment

Kuntai believes that to make good machines needs good machining equipment, this is why, every year Kuntai adds new machining equipment to improve productivity and precision. With the addition of advanced equipment and ever growing sales orders, Kuntai has expanded greatly these years and Kuntai’s new plant will be ready in 2026.

Customization Service

Kuntai sales team and aftersales service team always listen to customers’ requirements and feedback and Kuntai research and development team work out solutions to meet users’ real site laminating machine and cutting machine application need. With joint efforts, we can provide satisfactory customization service to customers with latest laminating cutting technology.

Strict and Systematic Quality Control

With over 40 years’ professional experience, Kuntai quality control department has profound knowledge and advanced tools to control laminating machine and cutting machine quality. CE and ISO certificates and Kuntai internal quality control policies and also cooperating experience with world’s leading companies guide machine quality inspectors every day.

1. Are you a trading company or a manufacturer?

We are a manufacturer with more than 40 years of manufacturing and R&D experience.

2. Where is your factory?

We are located in Yancheng, three and a half hours drive away from Shanghai, China. If by train, it only takes about 1hour 40mins to 2 hours.

3. Do you have a professional R & D department?

Yes we have. We have established our Kuntai R&D center with famous university Padova,Italy in Europe. Jiangsu Kuntai Machinery Co., Ltd as a professional manufacturer with more than 40 years experience in various Laminating Machine&Cutting Machine and other finishing machines.We always believe in technology- and market-oriented research. Every year, we develop a series of solutions to actual field application problems and develop new machines for our customers such as Tesla, Toyota, BMW of Germany, KIA of South Korea, 3M company and so on.

We can also provide customized machine services according to the actual needs of customers.

Our goal is to solve every field problem with customers, achieve better material finishing / processing results, and become customers' think tank.If you have any new ideas for our machines, please feel free to contact us!

4. How do I trust your quality?

We have a strict and scientific quality control management system, and we have passed the strict CE and ISO international certifications inspections. We have professional quality control personnel. For each step of our machine production, a set of quality control teams will be responsible for checking. The following steps can not be performed before the item passes all inspections. At the end of the machine assembly, a series of tests will be performed. We will not deliver it until the machine passes all tests. We provide a one-year warranty for our machines. Generally, our customers have used our machines for at least 5 years, 8 years or even 10 years. Throughout the life of our machines, spare parts will be replaced at cost.

5. How to operate the machine?

We have never used such a machine before. We just want to expand our business and start a new business. Do not worry! When buying our first machine, almost the majority of overseas customers were in the same situation. We have skilled and experienced follow-up service staff who have developed a complete solution to meet the needs of customers like you. In addition, we have a team of professional engineers with rich experience in installation and commissioning, which can perform installation, testing and operation guidance of machines overseas.

Wechat: ANNIELV88

Wechat: ANNIELV88