composite machine description

Kuntai Group

Generally speaking, a composite machine refers to a type of compositing equipment used in home textiles, clothing, furniture, automotive interiors, advanced textiles,and other related industries. It is mainly used for the production process of two-layer or multi-layer lamination of various fabrics, leather, film, paper, sponge, fibre, etc. Specifically, it can be divided into adhesive composite machine and non adhesive composite machine. Adhesive composite machine can be further divided into water-based adhesive composite machine, PU oil adhesive composite machine, hot melt adhesive composite machine, etc. Non adhesive composite processes often involve direct hot pressing bonding or flame burning composite between materials..

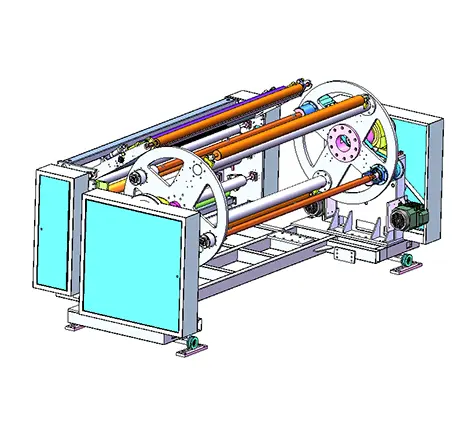

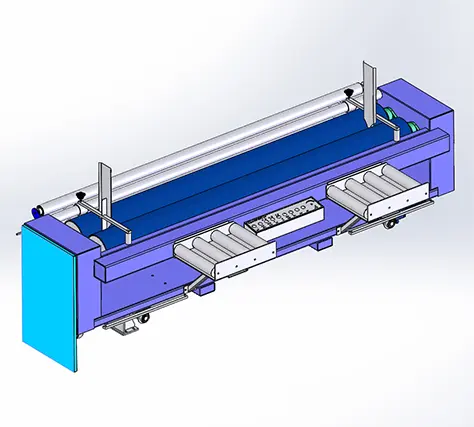

The working principle of a composite machine usually includes steps such as feeding, gluing, hot pressing, and cooling. During the operation, the materials of each layer enter through the feeding port of the composite machine, and then apply adhesive in the gluing unit. Then, they are bonded under high temperature and high pressure through the hot pressing unit, and finally cured through the cooling unit. Different models and applications of composite machines may vary, but their basic principles are the same.

When PTFE, PE, TPU and other functional waterproof and breathable films are used in laminating, water-proof and heat preserving, waterproof and protective, oil & water & gas filteration and many other different new materials will be created. The demands of garment industry, home textile industry, motor manufacturing, medical industry, environment protection industry will be met.

Kuntai's composite machine catagory covers a full range of the composite machines from water based glue composite machine to hot melt PUR glue composite machines, from composite machines for garment to composite machines to aircraft products.

Applicable adhesives

Kuntai Group

Hot melt PUR glue, Hot melt EVA glue, Water based glue, Solvent based glue, hot melt film, etc.

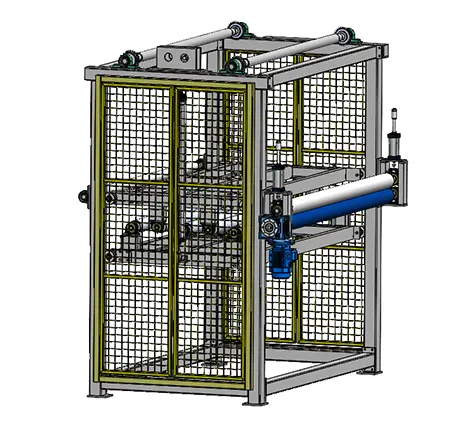

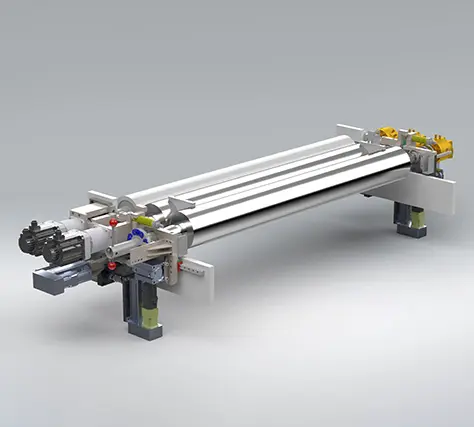

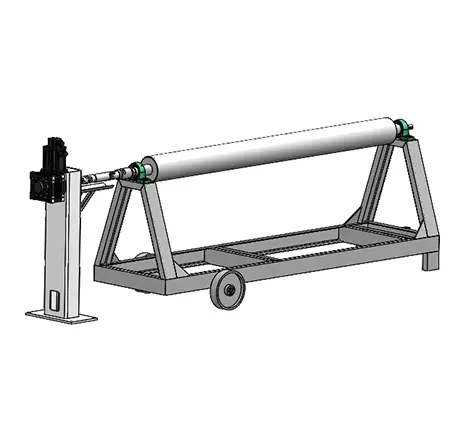

AccessoriesOption

01020304050607080910

composite Machine Features

Kuntai Group

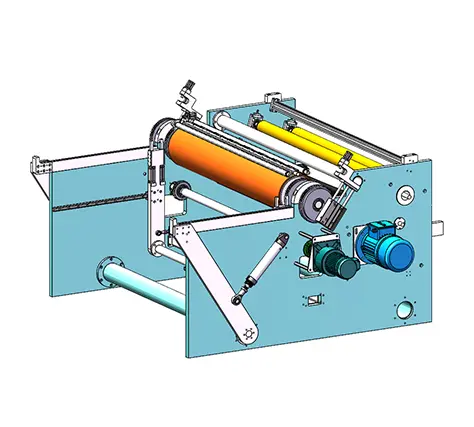

● Uniformly applying various types of glue onto textiles, nonwoven materials, foam, film/membrane, fibre,etc.

● Hot melt adhesive makes possible environmental friendly products and realizes no pollution during the whole process of lamination. Solvent based adhesive offers strong bonding and relatively lower production cost. Water based glue makes economical bonding possible. Various types of adhesive or bonding media have their own unique features and advantages.

● Various adjusting methods can be applied for gluing gap and lamination gap adjustment.

● Controlled by Programmable Logic Controller system with touch screen and modular designed structure, this machine can be easily and simply operated. Remote control plays a gread role in machine maintenance and aftersales service.

● Siemens, Schneider, Yaskawa, Omron, Keyence and many other international famous brands parts can be used in Kuntai composite machines.

● Different composite materials requires different tension control and feeding methods. Kuntai customizes the machine parts as per each base materials requirements and final product performance requirements.

● Various fabric and film and fibres spreaders,openers and width control devices feed materials smoothly and flatly.

● For different fabric, different fabric conveyor and expanding devices are available for choice. High productivity, high efficiency, high flexibility.

● Low maintenance cost and less running noise and more user friendly.

● When using functional waterproof moisture permeable films such as PTFE,PE and TPU, more materials which are waterproofing and insulated, waterproof and protective will even be invented by means of composite machines.

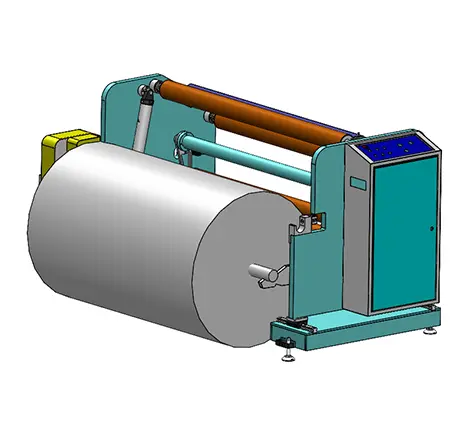

● For different application, different rewinding devices can be produced by Kuntai as per user requirements.

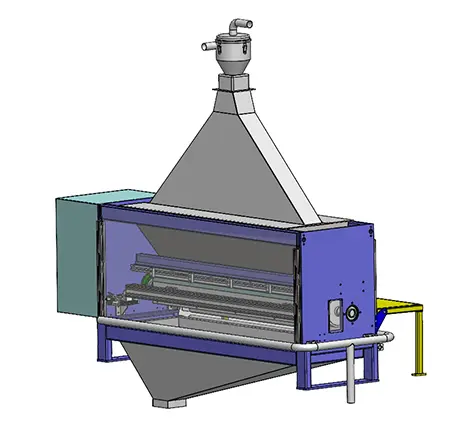

● Oil heater heating, electrical heating,electromagnetic induction heating and many other heating methods are available.

composite machine Technical Parameters (Customizable)

Kuntai Group

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

| Gap Adjustment | Servo Motor Control |

| Heating Method | Oil Heating, Natural Gas Heating, Electromagnetic Induction Heating, Electrical Heating Available for Customization |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 45-80kw, Customizable |

| Voltage | 220v, 380v, 415v, 440v, as per user's factory nearby power supply |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

composite machine Application

Kuntai Group

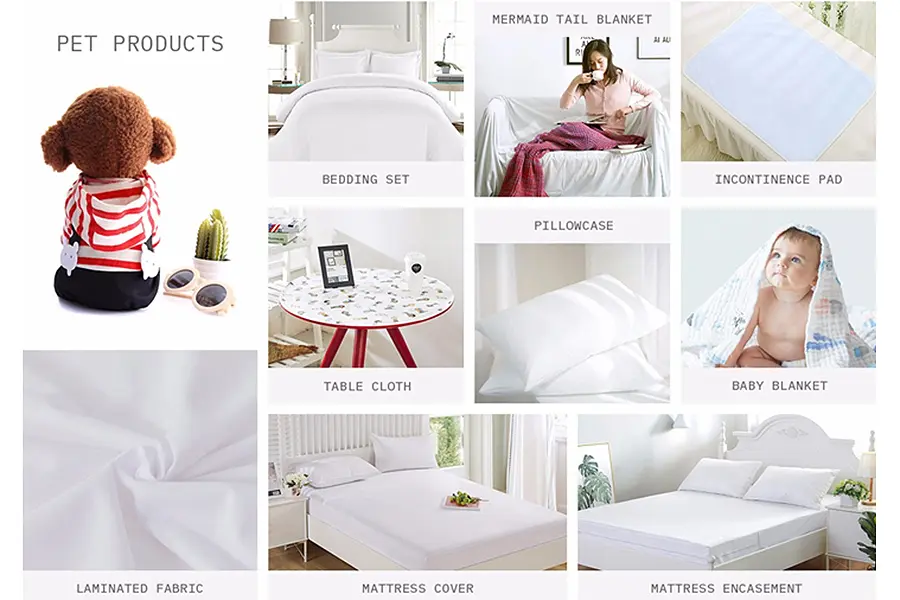

Composite machine is widely used in various industries, such as outdoor clothing, functional and protective clothing, auto interiors, home textiles and decoration, advanced textiles, footwear, packaging and many other industries. Composite machine can laminate below materials:

✓ EVA + PVC, PU or artificial leather

✓ EVA + fabric (For shoe materials, etc.)

✓ Neoprene + fabric (For diving fabrics, diving suits, etc.)

✓ PU foam + fabric (For bras, car interior seats, etc.)

✓ TPU film + fabric. (Used in mountaineering clothes, camouflage clothes, etc.)

✓ Breathable membrane + non-woven fabric. (For medical protective clothing supplies, etc.)

✓ Fabric + fabric: textile, jersey fabric, wool, nylon, velvet, terry cloth, suede, etc.

✓ Fabric + film, such as PU film, TPU film, PE film, PVC film, PTFE film, etc.

Packaging And Shipping

Kuntai Group

Composite Machine Inner Package: Protective Film, etc .

Composite Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88