prepreg machine description

Kuntai Group

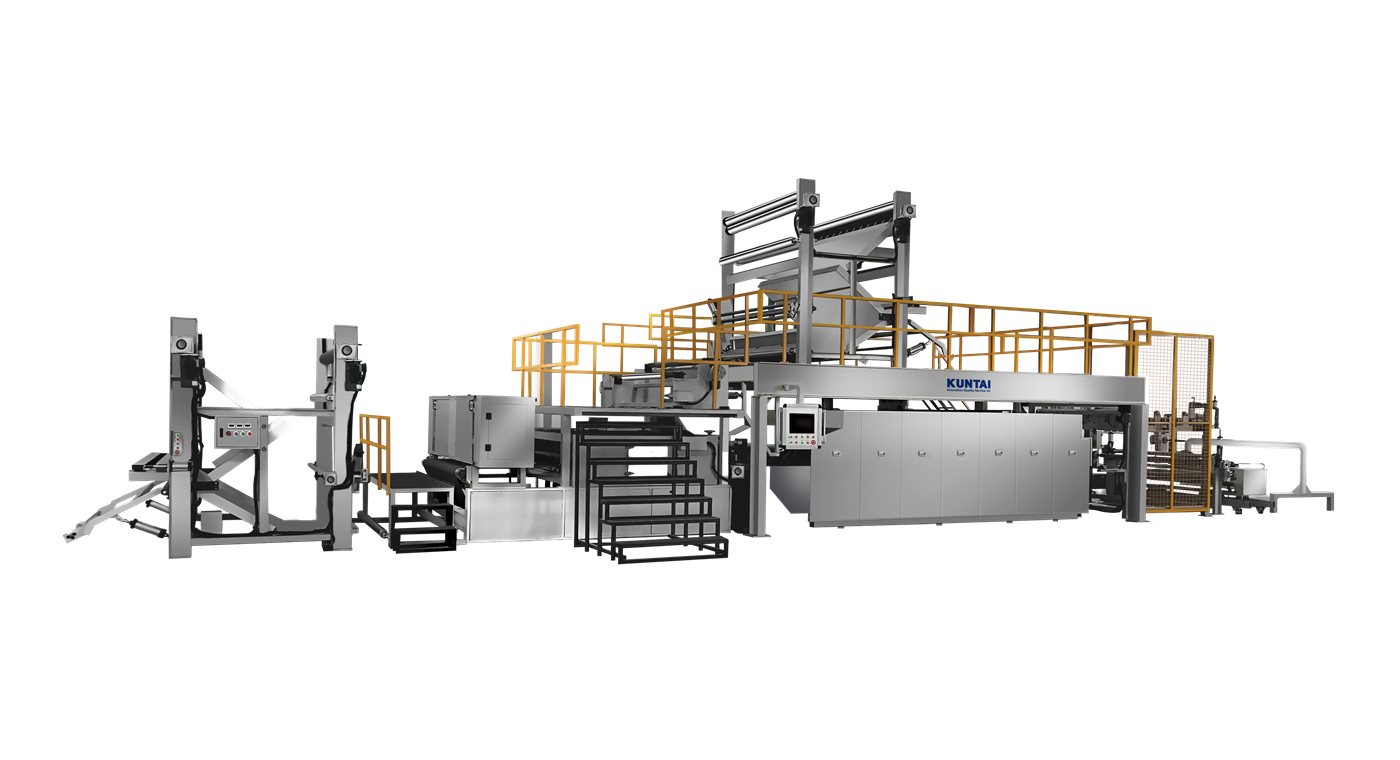

In modern industrial manufacturing, efficient and precise production lines are an important driving force for industry development. Kuntai UHMWPE Prepreg Machine, as a leader in this field, has become a recognized benchmark in the prepreg industry with its outstanding technical strength, advanced production technology, strict quality control, and good enterprise management.

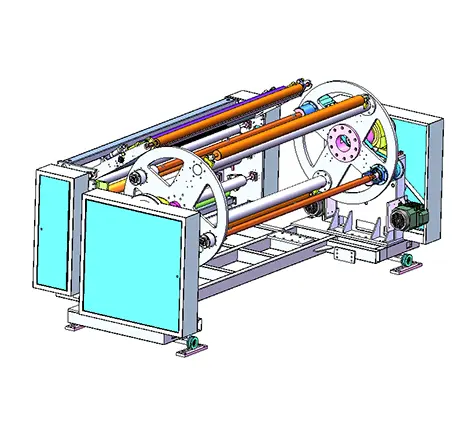

Kuntai UHMWPE prepreg machine integrates advanced automation equipment and intelligent management systems, achieving full automation production from UHMWPE to UD fabric. This highly automated UHMWPE prepreg method not only greatly improves production efficiency and reduces labor costs, but also ensures the stability and consistency of UD fabric quality. At the same time, the UHMWPE prepreg machine also has high flexibility and scalability, and can quickly adjust prepreg plans and UD fabric specifications according to market demand and customer needs.

Kuntai UHMWPE prepreg machine focuses on technological innovation and research and development, continuously introducing advanced prepreg technologies and equipment from home and abroad, actively absorbing and drawing on advanced experience in the industry. By establishing close cooperative relationships with universities, research institutions, and leading enterprises in the industry, Kuntai continuously innovates and develops a series of new products, technologies, and processes with independent intellectual property rights. These innovative achievements not only enhance the core competitiveness of Kuntai UHMWPE prepreg machine, but also make positive contributions to promoting the development of PE UD and Aramid UD fabric.

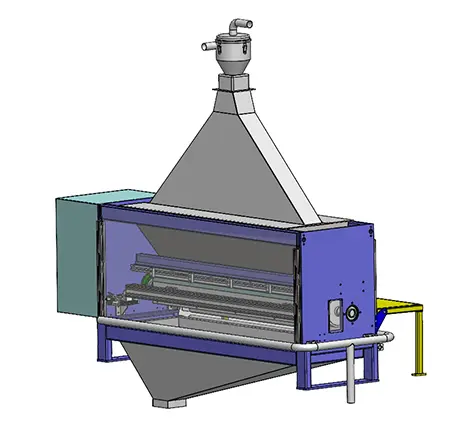

In the manufacturing process, Kuntai aramid UD UHMWPE prepreg machine first pretreats the high-performance fibers to make their surfaces clean and sticky, and then impregnates the fibers in organic resin to fully penetrate into the fibers. Next, the production line weaves or stacks the impregnated fibers to form the desired shape and thickness, and finally undergoes high-temperature curing treatment to tightly bond the organic resin with the fibers, forming high-strength and high rigidity composite materials.

Applicable adhesives

Kuntai Group

Resin, hot melt film, water based glue, etc.

AccessoriesOption

01020304050607080910

prepreg Machine Features

Kuntai Group

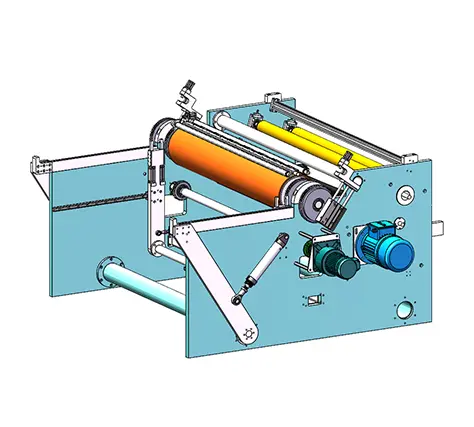

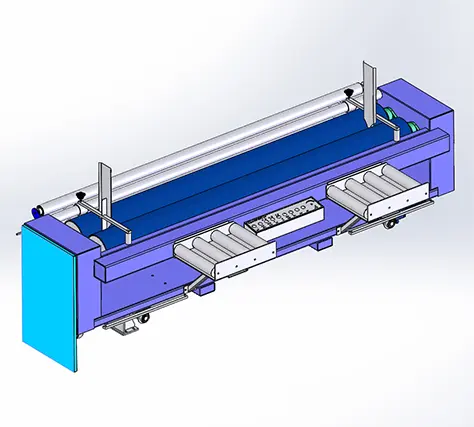

1. The UHMWPE UD and aramid UD prepreg machine adopts stable mechanical operation rollers and special-shaped devices to spread the fibre uniformly, impregnate with resin glue and lamination with the carrier PE film, dry and solidify, and then go through the 0/90º orthogonal lamination in the back. The product has excellent properties such as low density, abrasion resistance, impact resistance, and strong cutting resistance.

2. The UHMWPE prepreg machine uses resin adhesives to produce PE UD or aramid UD fabrics.

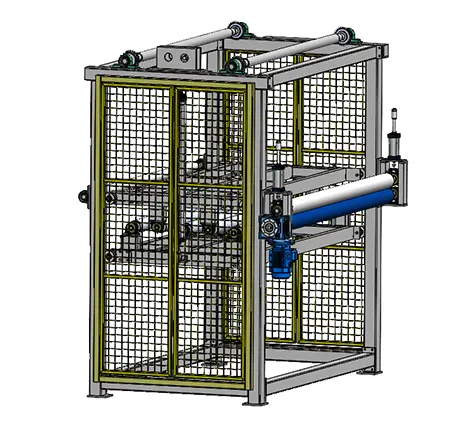

3. Adopt HMI+PLC control system, easy operation, high production efficiency, and reduce the tedious operation.

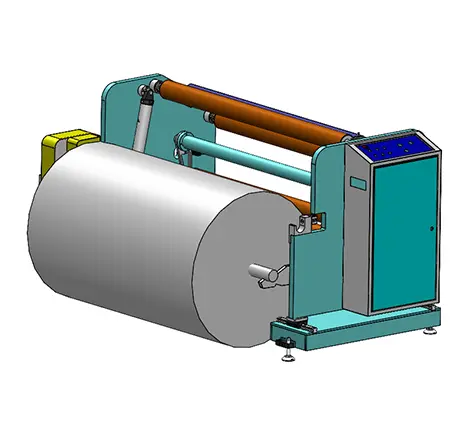

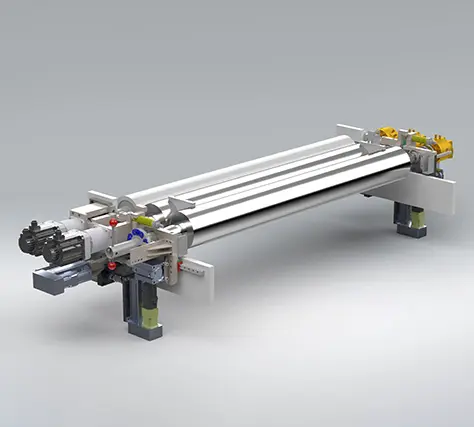

4. The mirror surface processing rollers are used for fibre pulling and fibre laying to ensure that the damage to the fiber performance is reduced to the greatest extent during the operation.

5. The machine adopts gear transmission, which has strong torque transmission and stability.

6. Kuntai UHMWPE prepreg machine has dual function of prepreging and also coating. User can choose to use prepreging or coating depends on the actual production need.

7. One of the key features of Kuntai UHMWPE prepreg machine is the stable tension control of fibre, which maximizing the preservation of fiber original performance.

prepreg machine Technical Parameters (Customizable)

Kuntai Group

| Machine roller width | 1800mm |

| Max material width | 1650mm |

| Gluing method | Prepreg glue, Imprepreg |

| Spreading method | Mechanical multi-roller+special shaped |

| Control mode | HMI+PLC |

| Drive control | Variable frequency drive |

| Heat source mode | Oil heater |

| Temperature control method | Module |

| Roller surface treatment | Mirror surface of the friction roller of the whole machine |

| Dynamic balance | Mirror roller heating roller of the whole machine |

| Total power | 90kw |

| Lamination speed | 3-11m/min |

| PLC Brand | Mitsubishi |

| Main Motor Brand | Siemens |

| Inverter Brand | Yaskawa |

| Electrical Parts Brand | Schneider/Omron |

| Temperature Control Brand | Fuji |

prepreg machine Application

Kuntai Group

Application and Usage of UHMWPE Prepreg Machine

- Space and Air craft (aerospace): aircraft fuselage, wings, vertical tail and other components

- Blades for wind turbines

- Automotive parts and components, such as body and chassis

- Recreational sports equipment

- Industrial structure and parts

- Military, defense industry

- Civil and Building Reinforcement

Packaging And Shipping

Kuntai Group

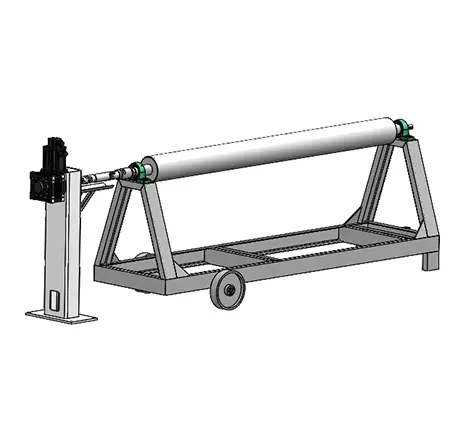

UHMWPE Prepreg Machine Inner Package: Protective Film, etc .

UHMWPE Prepreg Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88