2026-01-11

Advantages: This process, due to its high precision control of equipment, can reduce the damage to PTFE film caused by high-temperature hot pressing. The permeability and service life of the products are both superior to those of the filter materials laminated by adhesive method.

Method: In the initial process of the high-temperature hot-press laminating film technology, it is necessary to modify the PTFE film or perform special treatment on the base fabric to ensure the laminating effect of the high-temperature hot-press laminating process. Currently, the surface modification methods for PTFE films mainly include chemical solution modification and plasma modification; while the treatment of the base fabric mainly involves surface modification with PTFE emulsion.

Currently, our company manufacturers a type of hot pressing lamination machine, which through a high-temperature hot pressing process, combined with the heating electromagnetic/induction rollers , taking advantage of their uniform temperature feature, produces a PTFE film-laminated filter with uniform air permeability, strong film adhesion, and no easy peeling even at high temperatures.

How PTFE Film Laminated Filter Materials are made?

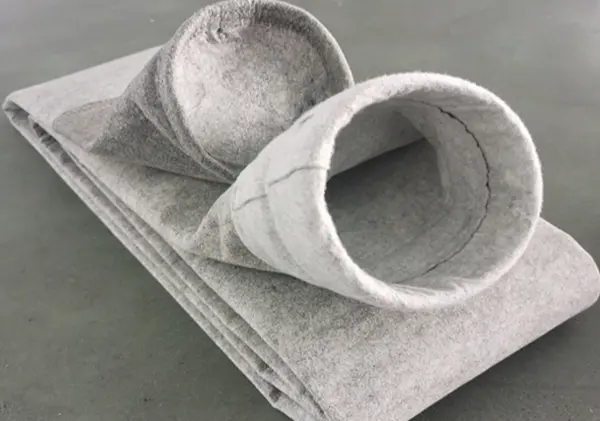

PTFE film laminated filter material is a new type of filter material formed by laminating a layer of polytetrafluoroethylene (PTFE) film on the surface of ordinary filter material. At present, the main PTFE laminating processes in the market are: adhesive method and high-temperature hot pressing process. The PTFE film laminated filter material used in the bag-type dust removal industry can achieve nearly zero emissions. Moreover, due to the non-adhesive property and low friction coefficient of the film, the powder cake will automatically fall off, ensuring the long-term stability of the equipment resistance. Thus, it fully demonstrates the superiority of the bag-type dust collector and is an ideal choice for filter materials.

Method: Currently, the adhesives developed and researched that can directly laminate low surface energy fluorine-containing materials mainly include solvent-based adhesives with organic amine complexes as initiators, hot melt adhesives containing thermoplastic fluorine-containing polymers, and water-based adhesives. Through different coating processes, a layer of adhesive is applied onto the base fabric, and the PTFE film is laminated to the base fabric.

Disadvantages: During the PTFE film laminating process, there are always issues such as whether the adhesive is evenly applied on the base fabric and whether the adhesive is prone to carbonization at high temperatures. Because the adhesive will clog the micro-porous structure of the PTFE film, it will cause a decrease in the breathability of the laminated filter material. Moreover, under high-temperature usage conditions, the adhesive will melt and even carbonize, further causing the micro-pores of the PTFE film to be blocked and resulting in the filter material detaching from the PTFE film, thereby affecting the service life of the laminated filter material.

2. High-temperature hot pressing process The high-temperature hot-press laminating process involves first subjecting the base fabric or PTFE film to a special surface treatment, and then, under certain pressure and temperature conditions, laminating the PTFE film and the base fabric together.

Disadvantages: During the PTFE film laminating process, there are always issues such as whether the adhesive is evenly applied on the base fabric and whether the adhesive is prone to carbonization at high temperatures. Because the adhesive will clog the micro-porous structure of the PTFE film, it will cause a decrease in the breathability of the laminated filter material. Moreover, under high-temperature usage conditions, the adhesive will melt and even carbonize, further causing the micro-pores of the PTFE film to be blocked and resulting in the filter material detaching from the PTFE film, thereby affecting the service life of the laminated filter material.

2. High-temperature hot pressing process The high-temperature hot-press laminating process involves first subjecting the base fabric or PTFE film to a special surface treatment, and then, under certain pressure and temperature conditions, laminating the PTFE film and the base fabric together.

Wechat: ANNIELV88

Wechat: ANNIELV88