product description

Kuntai Group

With the development of textile technology, the materials and processes of mattress protector have gradually diversified. For example, foam yarn is used for cool summer styles due to its three-dimensional structure, and the tufting process introduces synthetic fibers such as acrylic and polypropylene. Modern mattress protector design emphasizes coordination with spatial color tones, and selection should consider texture, size, and seasonal adaptability, forming styles such as flat, curtain skirt, and floor standing. As an important category in the home textile industry, its production follows the national standard FZ/T 43036-2016, covering physical properties, color fastness, and safety specifications. The industry positioning has also shifted from a single function to an overall design component for bedroom spaces.

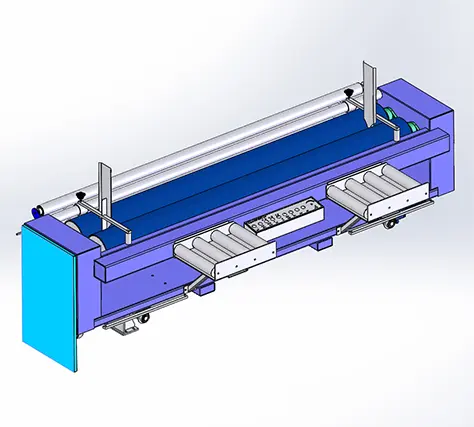

Among above deveopments in mattress protector, the most popular one is laminating mattress fabric with TPU film or PTFE film. Because of its waterproof and breathable capacity, TPU film is widely used in mattress protector lamination machine. Some high-end market targetted customers choose to use more soft PTFE film for better mattress protector.

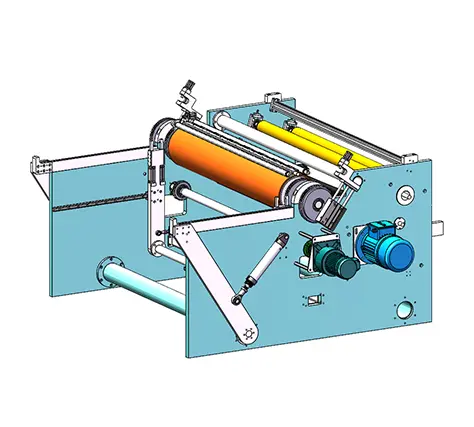

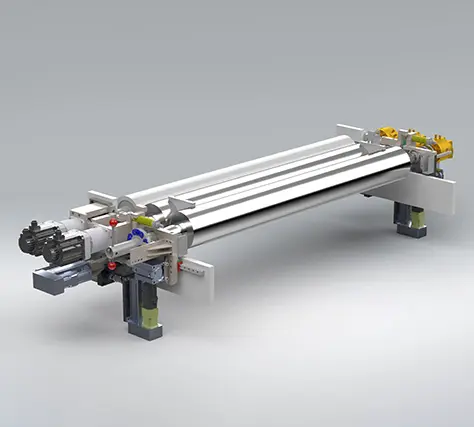

Due to the softness requirements and production cost control requirements, mattress protector lamination machine should do a very good job in controlling the glue quantity. Kuntai has designed and manufactured a series precise and glue saving gluing transfer devices.

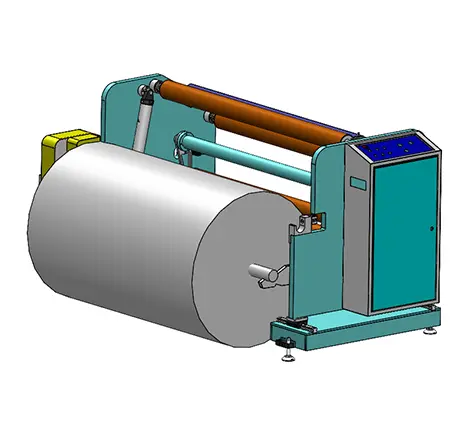

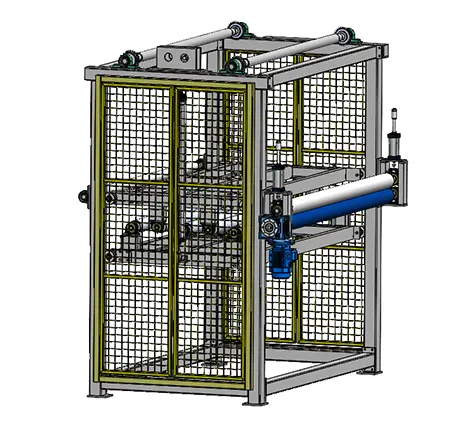

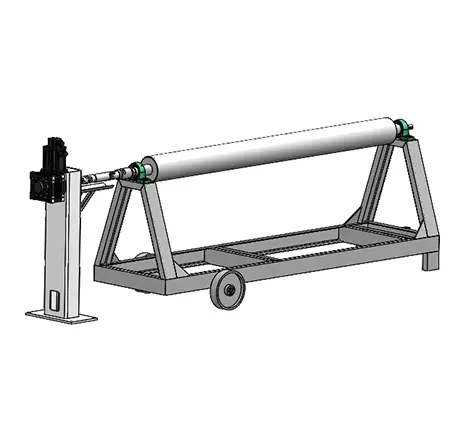

In order to reduce the mattress protector weight, thin TPU or PTFE film is widely used in mattress protector lamination machines. Thus the lamination machine should unwind and feed the film properly without breakage or bubbles or wrinkles.

Most of the mattress protectors use knitted fabric or cotton fabric, so mattress protector lamination machine should be equipped with a series of tension control device, feeding device and width control device, etc.

Applicable adhesives

Kuntai Group

Hot melt PUR glue, Hot melt EVA glue, Water based glue, Solvent based glue, hot melt film, etc.

AccessoriesOption

01020304050607080910

Machine Features

Kuntai Group

● Uniformly apply glue onto TPU film or PTFE film surface and make sure the least quantity glue is used to save glue cost and maintain the lightness and softness of mattress protector.

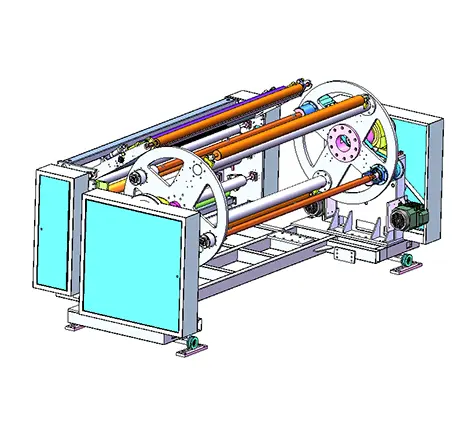

● For different mattress fabric, different unwinding devices, feeding devices, tension control devices, etc can be available for choosing the suitable mattress protector lamination machines.

● Precise and easy gluing gap and lamination gap adjustment is the key to laminate thin film/ membrane.

● PLC control and touch screen operation facilitates the lamination of mattress protector lamination machine.

● Siemens, Schneider, Yaskawa, Omron, Keyence and many other international famous brands parts can be used in Kuntai mattress protector lamination machines.

● Mattress fabrics related spreaders,openers and width control devices feed fabric smoothly and flatly, so that final product does not have bubble or wrinkle.

● Kuntai mattress protector lamination machine brings you continuous, protective and mass production

● Low maintenance cost and quiet operation process and healthier lamination work.

● When using advanced functional fabrics, products of advanced application can be produced in Kuntai mattress protector lamination machine.

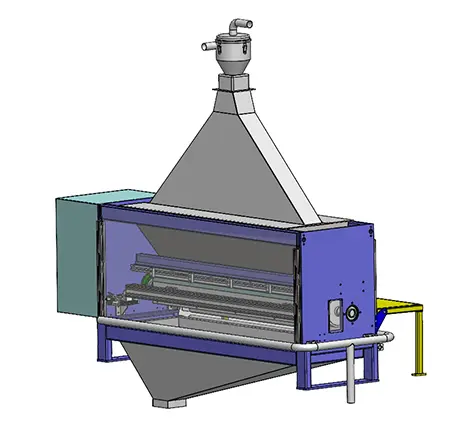

● Oil heater heating, electrical heating,electromagnetic induction heating and many other heating methods are available.

Technical Parameters (Customizable)

Kuntai Group

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

| Gap Adjustment | Servo Motor Control or Mechanical Control available for choice |

| Heating Method | Oil Heating, Natural Gas Heating, Electromagnetic Induction Heating, Electrical Heating Available for Customization |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 45-80kw, Customizable |

| Voltage | 220v, 380v, 415v, 440v, as per user's factory nearby power supply |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

Application

Kuntai Group

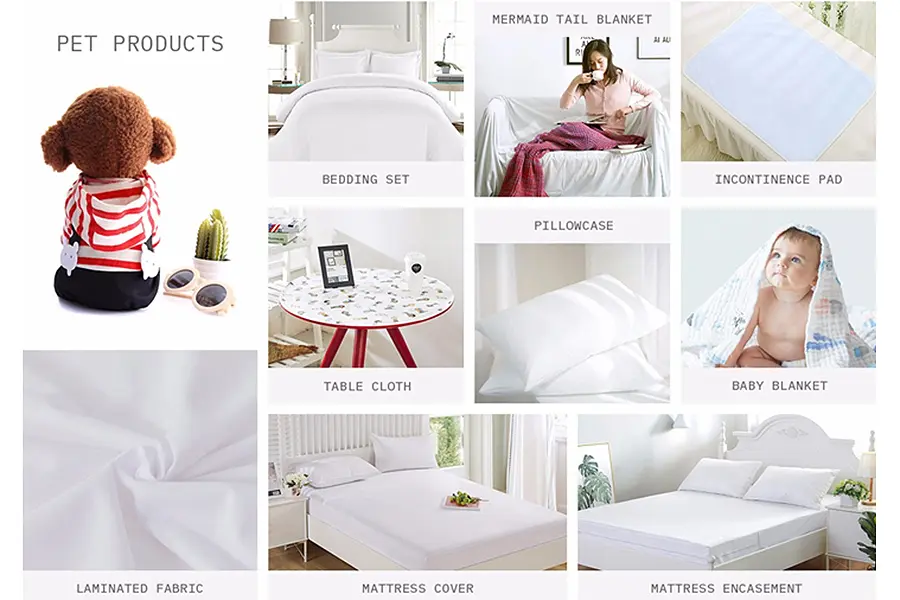

Mattress Protector lamination machine is widely used in middle and high home textile industries and it can also laminate the following items:

✓ Nonwoven+TPU for medical protection suits

✓ PVC + table fabric for table covers

✓ Fabric with foam or other materials for pets mat

✓ Cotton fabrics for babies wearings

Packaging And Shipping

Kuntai Group

Mattress Protector Lamination Machine Inner Package: Protective Film, etc .

Mattress Protector Lamination Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88