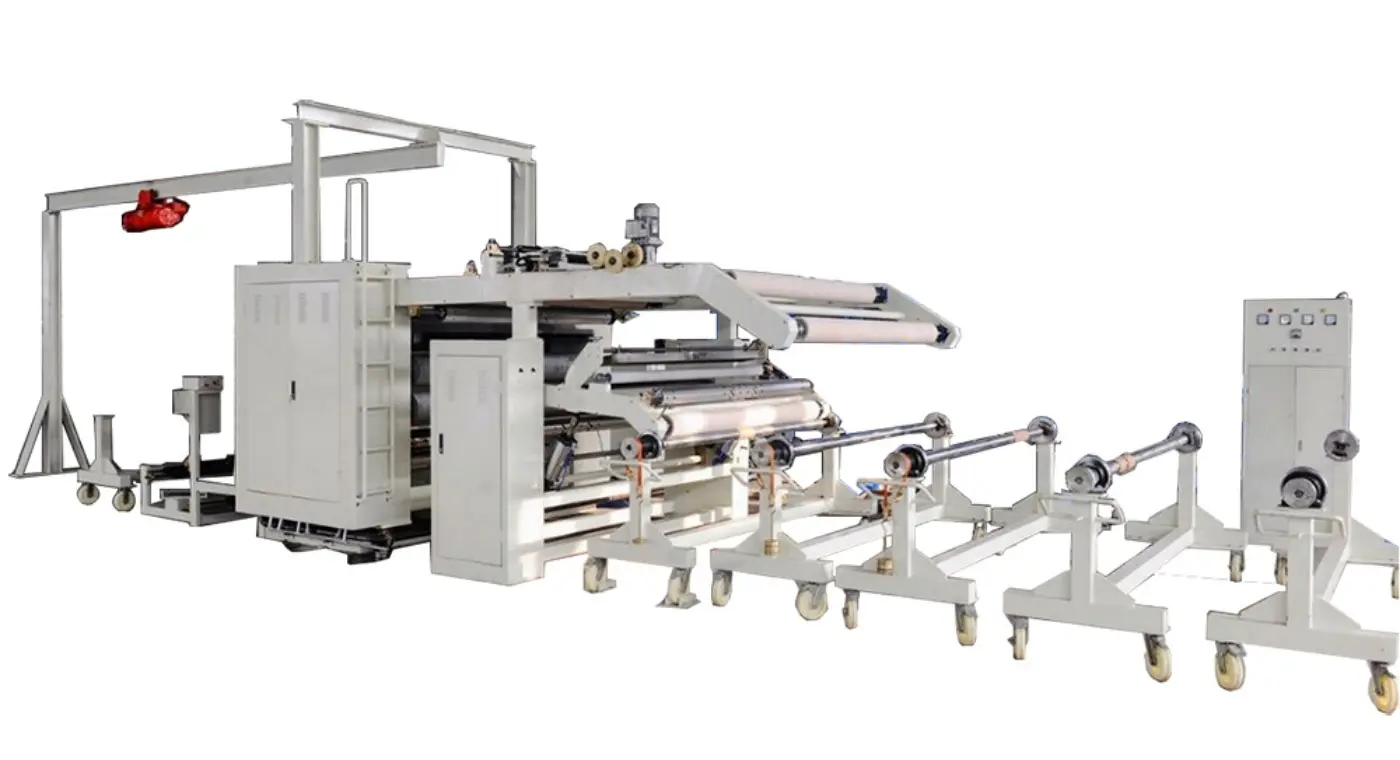

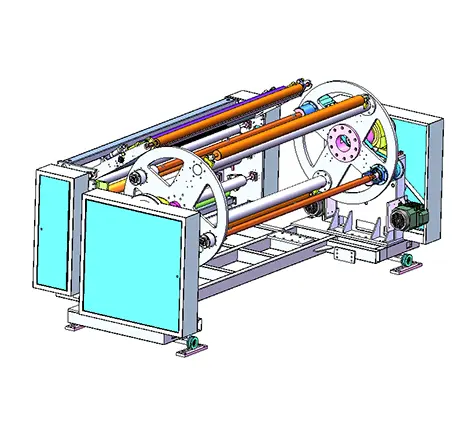

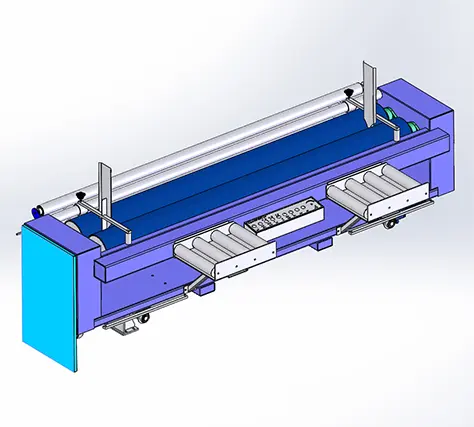

ptfe film bonding machine description

Kuntai Group

PTFE membrane is a microporous film produced by special processes such as pre mixing, extrusion, rolling, and biaxial stretching using polytetrafluoroethylene dispersed resin. It is divided into clothing membrane, PU micro waterproof membrane, filtration membrane, and purification membrane.

By utilizing this microporous structure, excellent waterproof and breathable functions can be achieved; In addition, due to the extremely small size and irregular vertical bending arrangement of the hole, wind cannot pass through, thus possessing characteristics such as wind resistance and warmth retention. After being laminated or bonded with other fabrics by PTFE film bonding machine, it is widely used in military clothing, medical clothing, casual clothing, special protective clothing for firefighting, anti-virus, immersion operations, outdoor sports clothing, shoes, hats, gloves and other accessories, as well as sleeping bags, tents, rain gear and other materials.

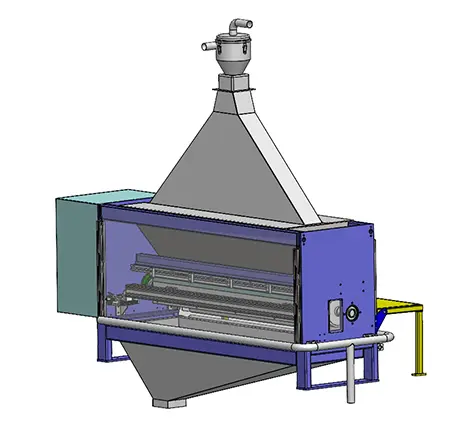

By utilizing the unique characteristics of polytetrafluoroethylene microporous membrane, such as node fibrillation, smooth surface, chemical resistance, air permeability, high air permeability, flame retardancy, high temperature resistance, strong acid and alkali resistance, and non toxicity, it can be used for atmospheric dust removal, air purification, etc. The product made of this membrane has a high filtration efficiency, reaching 99.99%, and nearly zero emissions; Low operating resistance and fast filtration speed; Long service life, reusable, thereby reducing operating costs. Mainly used for flue gas filtration in various industrial furnaces such as chemical, steel, metallurgy, carbon black, power generation, cement, and waste incineration. Polytetrafluoroethylene filtration membrane, the pore size of the membrane can be controlled between 0.2 and 15 μ m, and the porosity can reach over 85%. Because of this, Kuntai PTFE film bonding machine bonds PTFE film with fabric for filter products.

Though PTFE film cost is a bit higher than those of other films/membranes such as TPU, PU, PTFE film is widely used in various sectors of our life and industrial applications. Thus, PTFE film bonding machine is more and more popular as time goes on.

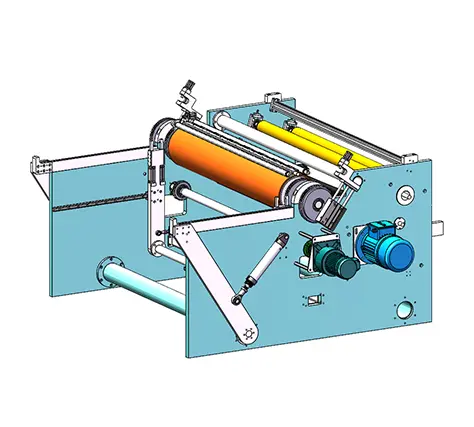

Currently, PTFE film bonding machine is generally divided into below catagories: thermal press bonding machine and glue bonding machine.

Applicable adhesives

Kuntai Group

Hot melt PUR glue, Hot melt EVA glue, Water based glue, Solvent based glue, hot melt film, etc.

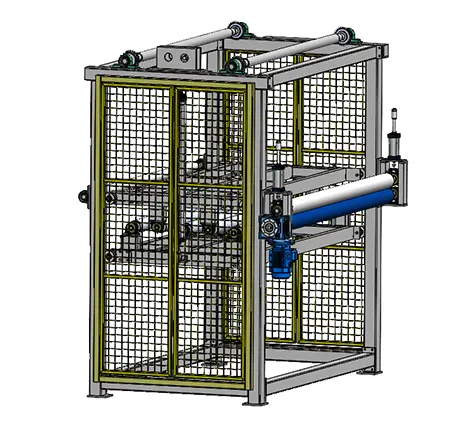

AccessoriesOption

01020304050607080910

PTFE Film bonding Machine Features

Kuntai Group

● Uniformly apply glue onto PTFE film surface and make sure the glue will not reduce the film itself breathability and other features and performance.

● For different application situations, different types of glue or bonding media or bonding method can be used in PTFE film bonding machine.

● Precise and easy gluing gap and lamination gap adjustment is very important to keep PTFE film flatness during bonding/lamination process.

● PLC control can record and save the gap, speed, other data of PTFE film bonding, so that the operators only need to read the previous preset data to recall the relavant operation for each product.

● Siemens, Schneider, Yaskawa, Omron, Keyence and many other international famous brands parts can be used in Kuntai PTFE film bonding machines.

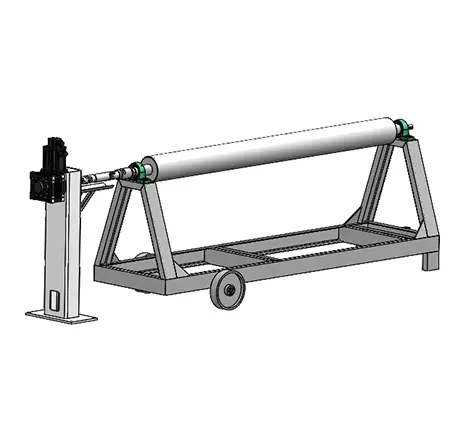

● PTFE film/membrane related spreaders,openers and width control devices feed PTFE film/membrane smoothly and flatly, so that final product does not have bubble or wrinkle.

● Fast speed, easy operation, good tension control better preserve PTFE film features in PTFE film bonding machine.

● Low maintenance cost, less labor required and more quiet running and more user friendly.

● Different types of glue and bonding media and heating methods are applicable in PTFE film bonding machines.

● Oil heater heating, electrical heating,electromagnetic induction heating and many other heating methods are available.

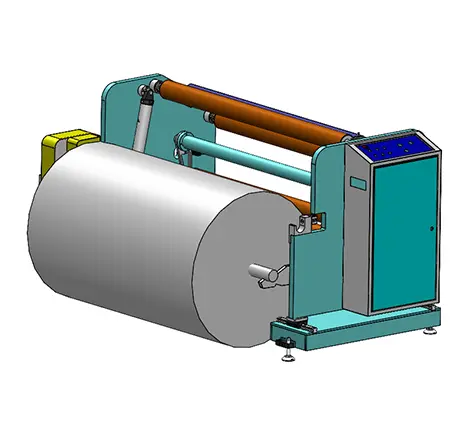

PTFE FILM BONDING MACHINE Technical Parameters (Customizable)

Kuntai Group

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

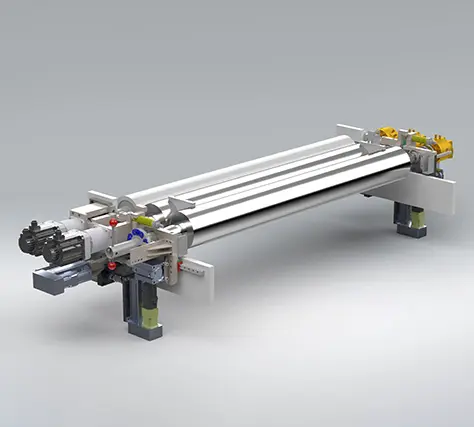

| Gap Adjustment | Servo Motor Control or Mechanical Control available for choice |

| Heating Method | Oil Heating, Natural Gas Heating, Electromagnetic Induction Heating, Electrical Heating Available for Customization |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 45-80kw, Customizable |

| Voltage | 220v, 380v, 415v, 440v, as per user's factory nearby power supply |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

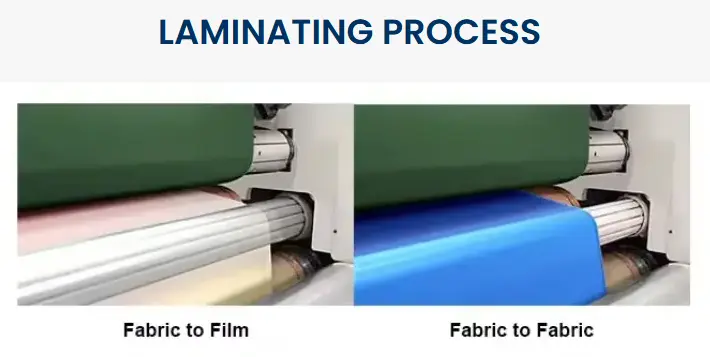

PTFE Film bonding process

Kuntai Group

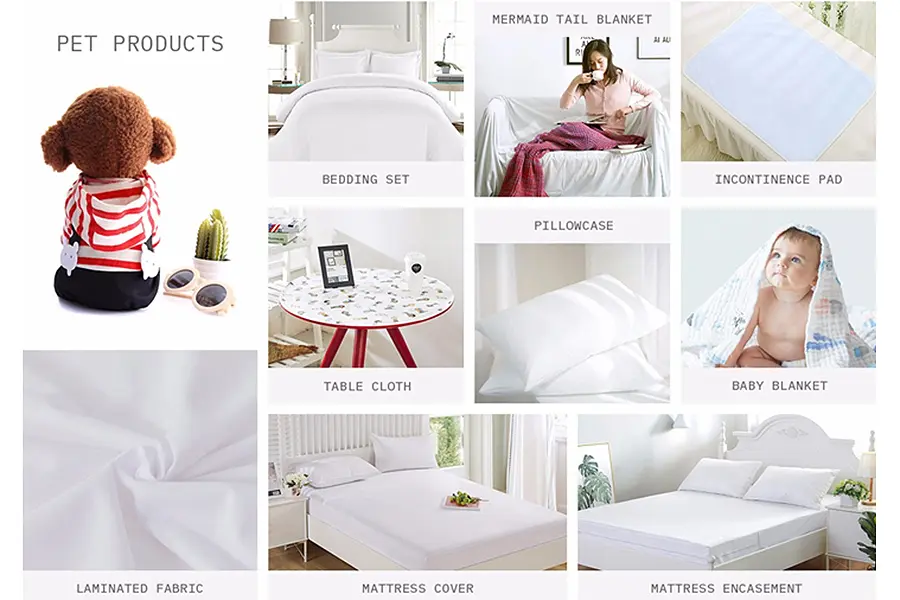

Application

Kuntai Group

PTFE film bonding machine is widely used in various industries, such as outdoor clothing, functional and protective clothing, auto interiors, home textiles and decoration, medical industry, advanced textiles, footwear, packaging and many other industries. PTFE film bonding machine can bond/laminate below materials:

✓ Glassfibre+PTFE Film

✓ Nonwoven+PTFE Film

✓ Knitted Fabric+PTFE Film

✓ Cotton Fabric+PTFE Film

Packaging And Shipping

Kuntai Group

PTFE Film Bonding Machine Inner Package: Protective Film, etc .

PTFE Film Bonding Machine Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88