The upcoming 2025 China Import and Export Fair, set to showcase advancements across various industry sectors, will highlight the growing significance of the Impregnation Machine For Ud Fabric. As the industry evolves, a recent report from MarketsandMarkets predicts that the global textile machinery market will reach USD 21 billion by 2025, driven by increasing demand for high-performance fabrics in sectors like automotive and aerospace.

Specifically, the impregnation process has become vital for enhancing the durability and performance of Ud fabrics, facilitating their application in innovative designs and multifunctional textiles. These machines not only improve production efficiency but also cater to the rising trends of sustainability and eco-friendliness in manufacturing practices. Therefore, the participation of leading manufacturers at the fair underscores the commitment to integrating cutting-edge technology and meeting the market's growing needs, setting the stage for future innovations in textile processing.

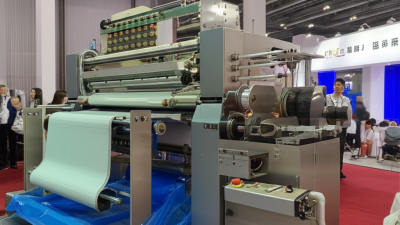

The 2025 China Import and Export Fair is set to showcase groundbreaking trends in impregnation technology specifically tailored for UD fabric. As the demand for lightweight yet durable materials continues to surge, manufacturers are innovating processes that enhance the performance of UD fabrics. Key advancements in chemical formulations and application techniques are expected to be unveiled, enabling more efficient impregnation processes that lead to better material properties such as reduced weight and increased strength.

Moreover, sustainability is becoming a focal point in the development of impregnation technologies. Companies are increasingly adopting eco-friendly materials and processes to minimize environmental impact while maintaining high-performance standards. At the fair, discussions will likely center around the integration of biodegradable resins and the development of water-based systems that reduce harmful emissions. These innovations not only cater to market demands but also align with the global push towards more sustainable manufacturing practices, making the event a pivotal platform for industry stakeholders to exchange knowledge and explore new opportunities.

The advent of innovative technologies is transforming the landscape of impregnating machines for UD fabric, particularly in preparation for the 2025 China Import and Export Fair. By focusing on enhancing the durability and performance of UD fabric, manufacturers are deploying advanced impregnation methods that improve resistance to environmental factors, mechanical stress, and wear over time. These innovations not only increase the lifespan of the fabric but also expand its application across various industries, including automotive and aerospace.

One effective approach is the integration of nanotechnology within the impregnation process. This allows for the creation of coatings that provide superior strength and flexibility while keeping the fabric lightweight. Furthermore, incorporating eco-friendly materials in the impregnation mixtures helps in not only achieving high-performance standards but also promoting sustainability in the textile industry.

Tips: When selecting an impregnation machine, consider features like temperature control and precision application to enhance the efficacy of the impregnation process. It's also advisable to stay informed about industry trends to ensure that your chosen equipment is aligned with the latest advancements. Finally, collaborating with suppliers who prioritize research and development can yield a competitive edge in producing high-quality UD fabrics.

The demand for impregnation machines in the textile industry is experiencing significant growth, driven by advancements in technology and increased consumer preferences for high-performance fabrics. According to a recent report by Technavio, the global market for impregnation machines is projected to grow at a CAGR of over 6% from 2021 to 2025. This surge is largely attributed to the rising demand for technical textiles, particularly in sectors such as automotive, aerospace, and sports apparel.

In the context of the 2025 China Import and Export Fair, the focus on impregnation machines specifically designed for UD (unidirectional) fabric highlights the industry's transition towards specialized machinery that enhances product features such as strength, durability, and water resistance. A report from Grand View Research indicates that the technical textiles market is expected to reach USD 225 billion by 2026, with a considerable portion of that being driven by innovations in impregnation technology. As manufacturers vie for a competitive edge, the integration of automation and smart technology in these machines will play a critical role in addressing market demands and improving manufacturing efficiency.

| Feature | 2023 Data | 2025 Projected Data | Growth Rate (%) |

|---|---|---|---|

| Market Size ($ Billion) | 2.5 | 4.0 | 60 |

| Annual Production Volume (Units) | 1200 | 1800 | 50 |

| Key End-users (Segment) | Apparel, Home Textiles | Apparel, Home Textiles, Automotive | N/A |

| Technological Innovations | Semi-automatic Machines | Fully Automated Systems | N/A |

| Major Regions | Asia, Europe | Asia, Europe, North America | N/A |

The development of impregnation machines for Ud fabric is witnessing a significant shift towards sustainable practices. Innovations in this area are focusing on reducing environmental impact while maximizing performance. For instance, the integration of advanced deposition technologies in the production of composite isogrid structures allows for efficient material application that not only lowers costs but also enhances durability. These processes ensure that the resulting isogrid structures meet the demands of various applications while adhering to eco-friendly standards.

Furthermore, the introduction of sustainable materials, such as nano-impregnated components in concrete, illustrates the broader trend of incorporating green technologies in manufacturing. By utilizing environmentally friendly resources, manufacturers can achieve a substantial reduction in both costs and carbon emissions. This approach aligns with the global push for sustainable development and highlights the importance of innovation in creating impregnated products that meet both market needs and environmental responsibilities. As the industry progresses toward the 2025 China Import and Export Fair, the emphasis on these sustainable practices is likely to shape the future landscape of impregnation technologies.

At the upcoming 2025 China Import and Export Fair, the spotlight will shine brightly on key players in the impregnation machine sector, particularly those focusing on UD (unidirectional) fabric technology. As competition intensifies within this niche market, various innovators are expected to showcase their latest advancements designed to enhance performance and efficiency in fabric treatments. Established brands will contend with emerging companies, each vying for recognition and market share in a landscape increasingly governed by consumer protection and regulatory scrutiny.

The recent antitrust investigations in China highlight the critical importance of fair competition, even in specialized sectors such as impregnation machinery. Stakeholders in this arena are urged to adopt transparent practices that align with evolving regulations. This focus on fairness not only fosters a healthier competitive environment but also encourages innovation, pushing companies to refine their technologies and production processes. As we approach the fair, it will be pivotal to observe how these dynamics unfold, influencing both strategic partnerships and consumer choices in the impregnation machine market.