In the ever-evolving landscape of manufacturing, the importance of efficient production techniques cannot be overstated. Among these, Coating and Laminating Machines play a pivotal role in enhancing product durability and aesthetic appeal across various industries. As we move through 2023, the demand for advanced coating and laminating solutions continues to rise, driven by the need for high-quality finishes and effective material protection. Businesses are increasingly turning to these machines to streamline operations, reduce waste, and improve overall productivity.

This article highlights the top ten Coating and Laminating Machines that stand out for their innovative features, speed, and reliability. By examining these cutting-edge technologies, we aim to provide insights into how they can revolutionize production processes while meeting diverse industry needs. Whether in packaging, textiles, or automotive applications, selecting the right equipment is crucial for staying competitive in today’s market. Join us as we explore the best options available in 2023, setting the stage for more efficient and effective manufacturing practices.

When selecting coating and laminating machines, it's essential to consider several key features that can significantly impact production efficiency. According to a report by Smithers Pira, the global market for coating machines is expected to grow by 4.8% annually, indicating the increasing importance of technology in production environments. Key features to look for include machine speed, precision, and adaptability to various substrates. Modern machines often operate at speeds exceeding 200 meters per minute while maintaining high accuracy in coating thickness. These factors are crucial for meeting tight production schedules without compromising quality.

Another critical aspect is the machine's ability to handle different types of coatings and laminates. Flexibility is vital in today’s fast-paced markets where custom solutions are often required. The latest machines often come equipped with advanced technology that allows for easy adjustments between different materials and formulations, ensuring seamless transitions during production runs.

Furthermore, energy efficiency and automation capabilities are becoming increasingly important, as highlighted in Market Research Future's projections indicating that machines with integrated automation can reduce operational costs by up to 30%. Such features not only enhance productivity but also contribute to sustainability initiatives by minimizing waste and energy consumption in manufacturing processes.

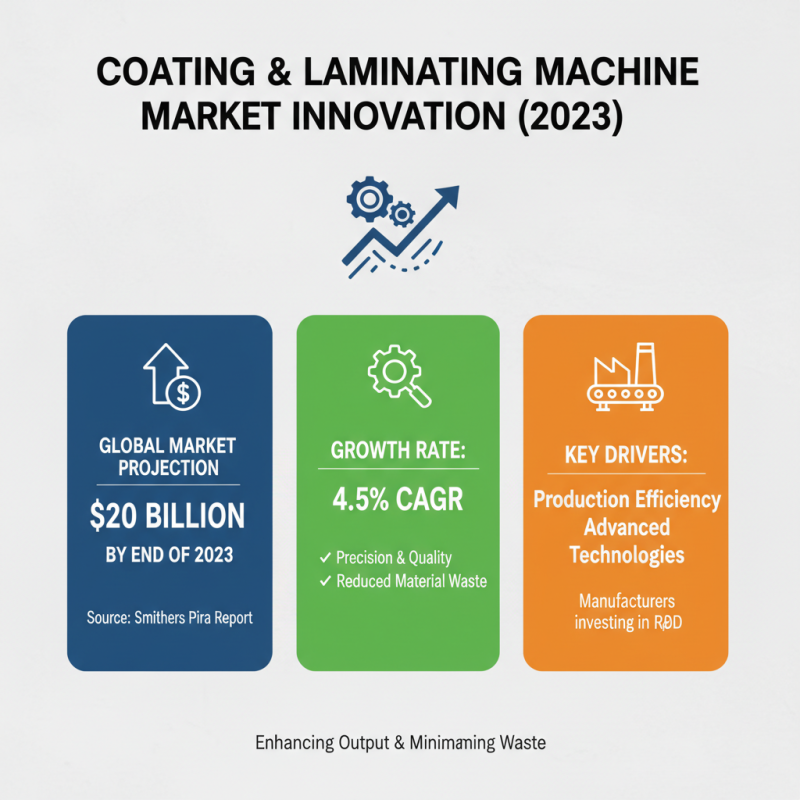

The coating and laminating machine market is witnessing significant innovation as manufacturers strive to enhance production efficiency in 2023. According to a recent industry report by Smithers Pira, the global market for coating and laminating technologies is projected to reach $20 billion by the end of this year, reflecting a compound annual growth rate of 4.5%. Companies are increasingly investing in advanced technologies that improve the precision and quality of coatings, thereby minimizing material waste and maximizing output.

Key features that distinguish top models in coating technology for 2023 include enhanced automation capabilities and smarter monitoring systems. These advancements not only streamline operations but also drive down labor costs and enable real-time quality control. In fact, studies show that automated machines can reduce the production time by up to 30%, making them a favored choice amongst manufacturers looking to optimize their operational workflows. The demand for eco-friendly coating solutions is also influencing machine design, with many top models now incorporating water-based or UV-curable coatings to meet stringent environmental regulations and consumer preferences.

Innovative technologies are profoundly influencing the coating and laminating industry, driving efficiency and enhancing production capabilities in 2023.

Advanced automation and smart manufacturing techniques are at the forefront, allowing for real-time monitoring and adjustments during the coating and laminating processes. This not only reduces error rates but also maximizes resource utilization, leading to significant cost savings. The integration of Industry 4.0 principles, such as the Internet of Things (IoT) and artificial intelligence, facilitates predictive maintenance and optimizes machine performance, ensuring continuous output and reduced downtime.

Moreover, the development of eco-friendly materials and processes has become a pivotal focus in the industry. The shift towards sustainable practices is evident in the increasing use of water-based coatings and recyclable laminating films, which minimize environmental impact without compromising product quality. Furthermore, advancements in application technologies, such as digital printing combined with coating, are enabling manufacturers to produce customized solutions with shorter lead times. These innovative approaches are not only redefining operational efficiency but also meeting the growing consumer demand for environmentally responsible and high-performance products.

When evaluating coating and laminating machines for your business, cost efficiency and return on investment (ROI) are paramount considerations. The initial cost of the machinery, while significant, should be viewed in the context of long-term savings and production capabilities. A machine that may seem expensive upfront could provide enhanced durability, lower maintenance costs, and improved throughput, ultimately leading to greater overall savings.

In addition to direct costs, businesses should consider the impact of efficient production on their operational workflow. High-performing coating machines often reduce the need for rework and waste while improving product quality. This results in better customer satisfaction and potentially higher market share. Investing in the right technology can streamline processes, cut down on labor costs, and optimize material usage, making it a strategic move for any company looking to enhance their competitiveness in the market. Therefore, a thorough analysis of both the financial and operational aspects will be crucial in ensuring that the investment pays off and aligns with the business's growth objectives.

This bar chart illustrates the cost efficiency (measured in ROI) of the top 10 coating and laminating machines in 2023, showcasing their return on investment for businesses looking to enhance production efficiency.

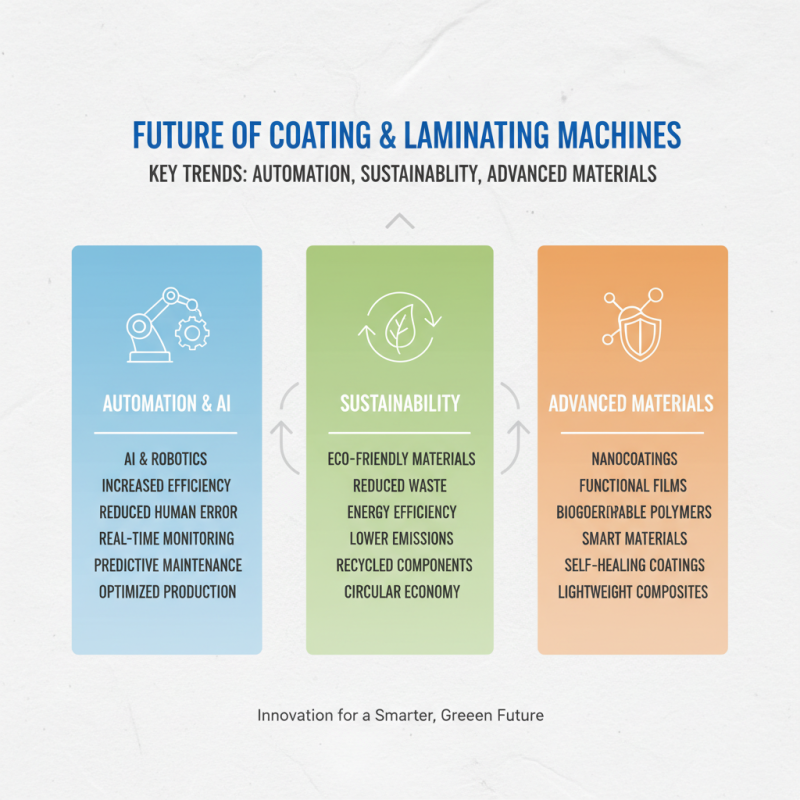

The future of coating and laminating machines is poised to be shaped by several key trends that emphasize automation, sustainability, and advanced materials. As manufacturing processes evolve, the incorporation of automation technologies, such as AI and robotics, is becoming paramount. These innovations enable machines to operate more efficiently, reduce human error, and optimize production lines. Manufacturers are increasingly adopting intelligent systems that can monitor performance in real-time, allowing for predictive maintenance and minimizing downtime. This shift not only enhances productivity but also contributes to a more streamlined operational workflow.

Sustainability also plays a crucial role in the development of next-generation coating and laminating machines. With growing awareness around environmental impacts, manufacturers are exploring eco-friendly materials and processes. This includes using water-based coatings and recyclable films, which significantly reduce the ecological footprint of production. Additionally, energy-efficient machines are being designed to lower energy consumption during operation, further supporting sustainability goals. The integration of such technologies aligns with industry demands for greener solutions while maintaining high-performance standards for production efficiency.

Moreover, advancements in materials science are driving innovation in this space. The emergence of smart materials that can respond to environmental stimuli opens new possibilities for coatings and laminates, offering enhanced functionality and performance. These materials can change properties based on temperature or humidity, providing added value to end products. As research continues to lead to the development of advanced coating technologies, manufacturers are set to benefit from enhanced capabilities and new market opportunities. With these trends shaping the future, the coating and laminating industries are on the cusp of groundbreaking advancements that align with modern production needs.