The textile industry is undergoing a significant transformation, driven by technological advancements and sustainability imperatives. At the forefront of this evolution is the Ud Fabric Production Line, which exemplifies innovation in fabric manufacturing. According to a report from the Global Textile Industry Outlook, the global market for technical textiles is projected to reach $210 billion by 2025, growing at a CAGR of 4.5%. This growth is largely fueled by increasing demand for high-performance fabrics in various sectors, including automotive, healthcare, and fashion. The upcoming 2025 China Import and Export Fair, or "第 138 届广交会", serves as a key platform to showcase the latest developments in textile technology, particularly the Ud Fabric Production Line, which integrates automation and eco-friendly practices to enhance production efficiency and reduce environmental impact. By restructuring traditional manufacturing methods, the Ud Fabric Production Line positions itself as a pioneering solution to meet the evolving needs of a rapidly changing market.

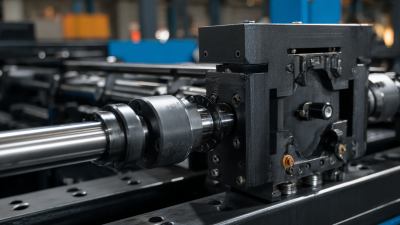

At the 2025 China Import and Export Fair, the textile industry is poised for a transformative leap, particularly in Ud fabric production. Innovative technologies are playing a pivotal role in this evolution. Among these advancements, the incorporation of thermoplastic prepregs and nonwoven multiaxial non-crimp fabrics stand out, ushering in a new era of high-performance textiles. Reports indicate that the market for technical textiles, including these innovative solutions, is projected to grow significantly, driven by demand across various sectors including aerospace and automotive.

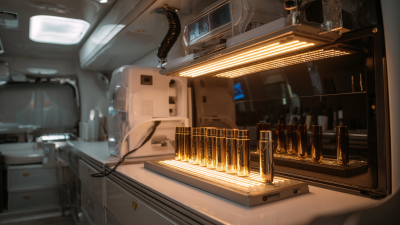

Furthermore, the establishment of open-access Innovation Centres by leading machine builders exemplifies the industry's commitment to fostering creativity and collaboration. Such initiatives allow for the exploration of pioneering techniques in Ud fabric production, which is essential for applications like ballistic protection and lightweight composite materials. The focus on bio-based materials and enhanced production techniques reflects a broader trend towards sustainability and efficiency within the textile sector. As companies continue to invest in research and development, the potential for groundbreaking advancements in Ud fabric production seems limitless, ultimately ensuring a robust future for the textile industry.

| Dimension | Data |

|---|---|

| Production Capacity (tons/year) | 5000 |

| Number of Production Lines | 10 |

| Percentage of Automation | 80% |

| Renewable Energy Usage (%) | 40% |

| Average Production Time per Batch (hours) | 24 |

| Waste Reduction Rate (%) | 30% |

| Employee Training Hours per Year | 1500 |

| R&D Investment (% of Revenue) | 5% |

| Current Trends in Fabric Design | Sustainable Fashion |

| Market Growth Rate (%) | 15% |

At the 2025 China Import and Export Fair, sustainability in the textile sector emerged as a pivotal theme, highlighting innovative practices that are transforming production lines and setting new industry standards. With increasing global pressure to address environmental concerns, many manufacturers showcased their commitment to sustainable practices, including the use of eco-friendly materials and water-saving technologies. These advancements not only reduce the environmental footprint of textile production but also appeal to an increasingly conscientious consumer base.

Moreover, the fair featured discussions on circular economy principles, where textile producers are exploring ways to recycle fibers and reduce waste. Brands are collaborating with suppliers to ensure that their entire supply chain adheres to ethical and sustainable standards. As the industry moves toward more sustainable models, the insights gathered from this year's fair will likely influence future practices, prompting a more responsible approach to textile manufacturing. This shift not only addresses ecological challenges but also opens up new market opportunities for businesses that prioritize sustainability.

The 138th Canton Fair showcased significant advancements in the production of Ud fabrics, highlighting the evolving landscape of the textile industry. Key players in this sector, including renowned manufacturers and innovative startups, demonstrated their latest technologies and sustainable practices. These participants are not only focused on enhancing fabric quality but also on reducing environmental impact through the use of eco-friendly materials and energy-efficient production methods.

Emerging trends in Ud fabric manufacturing emphasize customization and versatility, catering to the diverse needs of the global market. Companies are incorporating digital solutions for better design precision and quicker production cycles. Furthermore, the rise of smart textiles, equipped with functionalities like moisture management and temperature regulation, signals a shift towards high-tech applications in fashion and activewear. As the textile industry continues to evolve, collaboration among key players at events like the Canton Fair will be crucial in driving innovation and shaping the future of Ud fabric production.

As the textile industry continues to evolve, the Ud fabric production line has quickly gained prominence, particularly showcased at the 2025 China Import and Export Fair. However, despite the burgeoning market potential, Ud fabric producers are faced with various challenges in a competitive global landscape. According to a report by Technavio, the global technical textiles market is projected to grow by over $30 billion from 2021 to 2025, indicating an increasing demand for innovative fabrics like Ud. This demand offers significant opportunities for producers to cater to diverse industries, from automotive to medical textiles.

To successfully navigate these market dynamics, Ud fabric producers must adopt agile supply chain practices and invest in sustainable production methods. A key challenge lies in balancing cost efficiency with environmental sustainability, as consumers increasingly prioritize eco-friendly products. As noted in a McKinsey report, companies that commit to sustainability initiatives can enhance their marketability by up to 20%.

**Tips:**

1. Invest in R&D to drive innovation and enhance product offerings.

2. Collaborate with local manufacturers to streamline supply chains and reduce costs.

3. Focus on building strong online presence and digital marketing strategies to reach a broader audience.

The textile industry is poised for a transformative future as demonstrated at the 2025 China Import and Export Fair. With the introduction of innovative technologies and sustainable practices, manufacturers are learning valuable lessons that could redefine production lines. A significant focus is placed on automation and smart textiles, leading to enhanced efficiency and reduced waste. Attendees observed how these advancements not only meet the growing consumer demand for eco-friendly products but also streamline operations.

Tips for manufacturers looking to adapt include investing in research and development to integrate smart technology into production. Collaboration with tech companies can also yield breakthroughs in sustainable materials and processes. Engaging with trade exhibitions will provide valuable insights into emerging trends and consumer preferences, allowing brands to remain competitive in a fast-evolving market.

Moreover, sustainability initiatives are key. Implementing circular economy principles helps reduce environmental impact while meeting regulatory demands. Attending trade fairs can also facilitate networking with like-minded businesses, fostering partnerships that drive innovation. Brands that embrace these future directions will position themselves at the forefront of the textile industry’s evolution.