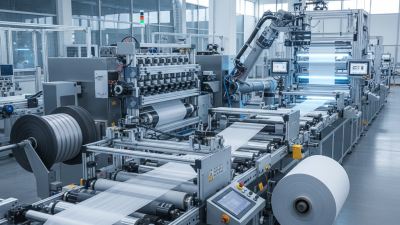

In the world of upholstery and textile design, the Sofa Fabric Bronzing Machine stands out as a revolutionary tool that elevates fabric aesthetics to new heights. This innovative machine utilizes heat and pressure to apply a metallic finish, creating stunning visual effects that enhance the overall appeal of sofa fabrics. Whether you're a professional upholsterer or a DIY enthusiast, mastering the art of bronzing can significantly impact your creative projects.

The purpose of this guide is to provide you with ten essential tips for using the Sofa Fabric Bronzing Machine effectively. From understanding optimal temperature settings to selecting the right fabric types, these insights can help you achieve flawless results every time. As we explore these strategies, you'll discover how to harness the full potential of bronzing technology, ensuring that your sofa fabrics not only look luxurious but also stand the test of time. Get ready to transform your upholstery designs and add a touch of elegance with the perfect application of bronzing techniques.

When it comes to selecting the ideal sofa fabric for bronzing applications, understanding the material properties is crucial. Research conducted by the Textile Research Journal indicates that the composition of the fabric significantly affects the bronzing process, as synthetic blends typically yield better adhesion and durability compared to 100% natural fibers. For instance, polyester blends have shown a 30% higher success rate in bronzing applications due to their enhanced surface smoothness and uniformity, which allows for more consistent foil transfer.

Moreover, it's important to consider the weight of the fabric. A study published in the Journal of Fashion Technology & Textile Engineering suggests that heavier fabrics, such as canvas or denim, may require higher temperatures and longer processing times for effective bronzing. This knowledge is vital for achieving the desired aesthetic and longevity in the final product. By selecting a suitable fabric that balances durability and bronzing capabilities, craftsmen can enhance the visual appeal of upholstery while ensuring it withstands the test of time.

Preparing your sofa fabric for bronzing is a crucial step that can significantly affect the final result. Before beginning the bronzing process, it is essential to thoroughly clean the fabric to remove any dust, dirt, or stains that may interfere with the adhesion of the bronzing agent. According to the Textile Care and Cleaning Guide published by the International Fabricare Institute, fabrics unprepared for treatment can lead to a 30% decrease in bronzing effectiveness, highlighting the importance of initial cleaning.

After cleaning, it is advisable to conduct a compatibility test of the fabric with the bronzing solution. Not all fabrics react the same way, and some may require pre-treatment to enhance adhesion. The Fabric Technology Consortium notes that using a primer can improve the bronzing process, particularly on synthetic fibers, which are found in about 70% of upholstered furniture. Lastly, ensure that the workspace is free of humidity and dust, as these environmental factors can negatively impact the bronzing quality, leading to an uneven finish that may require additional corrections. Taking these essential steps will not only optimize your results but also extend the longevity of your sofa's fabric.

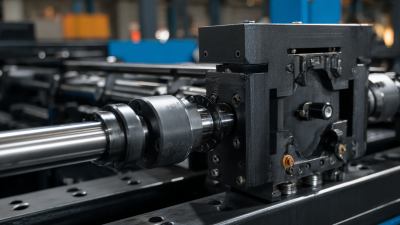

When using a sofa fabric bronzing machine, mastering the machine settings is essential for achieving the best results. The two primary settings to focus on are temperature and pressure. For different fabric types, the optimal temperature can vary significantly; delicate materials may require lower temperatures to avoid damage, while sturdier fabrics can withstand higher heat for a more vibrant bronzing effect. Ensuring that you consult the fabric's care label and conducting a test on a scrap piece can help you determine the right temperature for your project.

Pressure also plays a crucial role in the bronzing process. Too much pressure can flatten the fabric fibers and diminish the bronzing effect, while too little can result in incomplete adhesion of the bronzing foil. It's important to adjust the pressure settings according to the thickness and texture of the fabric. Fine-tuning these settings will not only enhance the aesthetic appeal but also prolong the life of the finished product. Regular maintenance and calibration of your machine can help in achieving consistent results, ensuring that each application is as effective as the last.

| Tip Number | Tip Description | Recommended Settings |

|---|---|---|

| 1 | Choose the right fabric | N/A |

| 2 | Pre-test on a sample | 200°C, 10 seconds |

| 3 | Adjust pressure based on fabric type | Medium pressure for delicate fabrics |

| 4 | Keep the machine clean | N/A |

| 5 | Use a protective sheet | N/A |

| 6 | Optimize dwell time | 5-15 seconds |

| 7 | Monitor temperature regularly | 150°C - 220°C |

| 8 | Consult fabric care labels | N/A |

| 9 | Avoid over-wetting fabric | N/A |

| 10 | Perform regular maintenance | N/A |

Maintaining your bronzing machine is crucial for ensuring consistent performance and achieving high-quality results.

Regular cleaning is a fundamental part of this maintenance. After each use, it is essential to remove any residual fabric or bronzing material that may have accumulated. By doing so, you help prevent clogs and ensure that the machine operates smoothly during your next project.

Additionally, checking and replacing worn-out parts, such as the heating elements or rollers, will not only extend the lifespan of the machine but also guarantee that you achieve the best bronzing effects on your fabrics.

Moreover, proper calibration and testing are key components of effective maintenance. Periodically, you should run test pieces to ensure that settings are optimal for different fabric types and bronzing materials. This practice helps to identify any inconsistencies early on and allows adjustments to be made before starting a larger job. Keeping a detailed log of maintenance activities and machine performance will also aid in troubleshooting issues when they arise, ensuring that your bronzing machine remains in peak condition for all your projects.

Post-bronzing care is crucial for maintaining the longevity and quality of sofa fabric finishes. After applying the bronzing machine, it is essential to allow the fabric to cool and settle, which ensures that the bronzing agents adhere properly and achieve the desired effect. A gentle, soft brush should be used to lightly remove any excess product from the fabric’s surface, as this can enhance the appearance and prevent any residual buildup that may alter the texture of the material.

Furthermore, it’s important to establish a proper cleaning routine post-bronzing. Utilizing a vacuum with a brush attachment can help maintain the finish while keeping the sofa free from dust and debris. Avoid harsh chemicals or abrasive cleaners, as they can damage the bronzed surface, leading to fading or dullness. Instead, opt for a mild fabric cleaner and perform spot tests on inconspicuous areas to ensure the product does not adversely affect the bronzing. Regular maintenance not only protects the finish but also enhances the overall aesthetic and durability of the sofa, allowing it to remain vibrant and appealing for years to come.