In the realm of advanced manufacturing, the optimization of processes is crucial for enhancing quality and efficiency. One such critical process is the "Thermohydraulic Coating Automatic Cutting," which plays a pivotal role in various industrial applications. This innovative technique combines the principles of thermohydraulic technology with automated cutting methods, resulting in precise and efficient material processing. As industries increasingly seek to improve productivity and reduce waste, understanding how to optimize this process becomes paramount.

The integration of automation in thermohydraulic cutting not only streamlines production but also ensures consistent quality and performance. By focusing on key factors such as cutting speed, temperature control, and material compatibility, manufacturers can achieve optimal results in their operations. Furthermore, continuous advancements in technology provide new opportunities for enhancing cutting precision and reducing operational downtime.

This article will explore effective strategies for optimizing Thermohydraulic Coating Automatic Cutting, delving into best practices, challenges, and emerging trends that influence this dynamic field. Through a thorough examination, we aim to equip industry professionals with valuable insights that will foster improved operational outcomes and drive innovation in manufacturing processes.

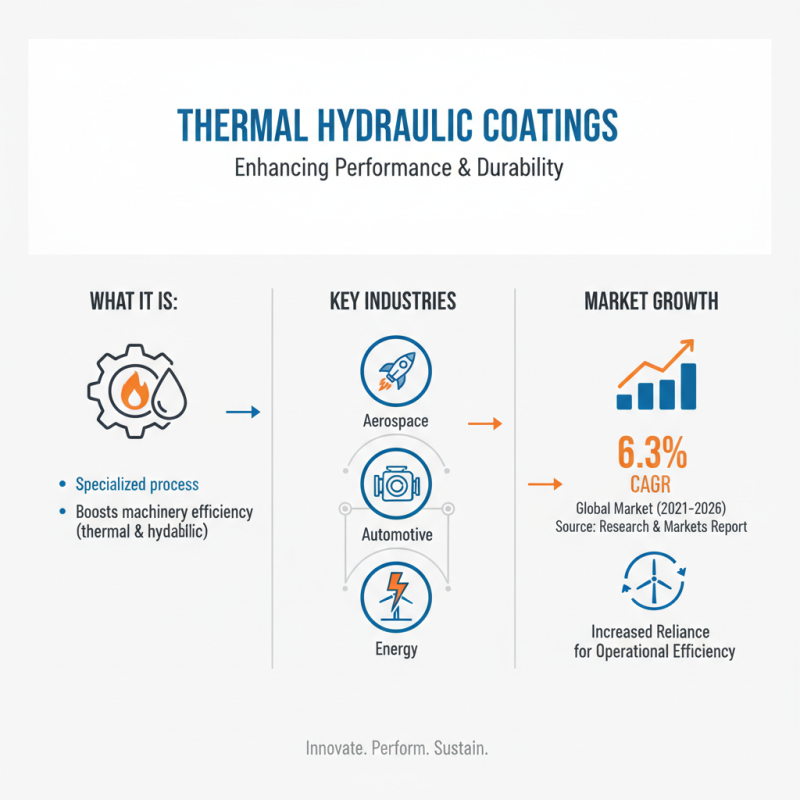

Thermohydraulic coating refers to a specialized process that enhances the thermal and hydraulic performance of machinery and components in various industries. This type of coating is essential in sectors such as aerospace, automotive, and energy, where thermal efficiency and durability are critical. According to a report by Research and Markets, the global market for thermal coatings is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2026, underscoring the increasing reliance on these materials for improved operational efficiency.

The significance of thermohydraulic coatings lies in their ability to withstand extreme temperatures and corrosive environments. For instance, in the aerospace industry, components coated with thermohydraulic materials can maintain their structural integrity even under conditions exceeding 1500 degrees Fahrenheit. This capability not only extends the lifespan of critical components but also reduces maintenance costs—a study by McKinsey & Company highlights that implementing advanced coatings can lead to a 15-20% reduction in lifetime operational costs for specific applications. As industries continue to focus on sustainability and efficiency, the adoption of thermohydraulic coatings will likely become a standard practice to meet performance demands while minimizing environmental impact.

When optimizing the automatic cutting process in thermohydraulic coating, several key factors play a significant role in achieving the best results. The efficiency of the cutting equipment, such as slicers and specialized cutting systems, is crucial for high-volume operations across various industries. These machines must be regularly maintained to ensure they operate at their peak efficiency, thereby reducing downtime and increasing productivity.

Tips: Regular calibration of the cutting machinery can help in maintaining precision and consistency in cuts. Additionally, investing in higher quality materials can significantly reduce wear and tear on equipment, leading to longer service life and better overall performance.

Another important factor to consider is the proper setup of cutting parameters. Adjusting the speed, pressure, and tooling of the automatic cutting systems can greatly impact the quality of the thermohydraulic coatings. Understanding the specific requirements of the material being cut will help in fine-tuning these parameters for optimal results.

Tips: Conducting regular training sessions for operators can enhance their understanding of system adjustments, ensuring that they can respond to material variances promptly. Implementing a feedback loop to gather insights from the cutting process will also help in continuously improving setup accuracy and efficiency.

Optimizing thermohydraulic coating automatic cutting techniques can significantly enhance productivity and product quality. To start, it’s essential to assess the cutting equipment and its settings. According to the *Optimized Cutting Techniques Report 2022*, the appropriate selection of cutting speed and feed rate can increase cutting efficiency by as much as 30%. Conducting thorough tests to determine the optimal parameters based on the specific material properties of the thermohydraulic coating is critical to ensuring a smooth cutting process.

The next step involves the implementation of real-time monitoring systems. Utilizing advanced software and sensors can facilitate immediate adjustments during cutting operations. A study published in the *Journal of Manufacturing Science* highlighted that integrating monitoring technologies reduced waste by 25% and improved overall accuracy in coating applications. Training operators to interpret data from these systems effectively is equally important to maximize their potential, ensuring adjustments can be made swiftly to maintain optimal conditions. By refining these cutting techniques systematically, companies can achieve superior results in their thermohydraulic coating applications.

| Cutting Technique | Optimal Speed (m/min) | Cut Quality Rating (1-10) | Material Thickness (mm) | Temperature (°C) |

|---|---|---|---|---|

| Laser Cutting | 10 | 9 | 5 | 100 |

| Plasma Cutting | 8 | 8 | 8 | 120 |

| Water Jet Cutting | 5 | 10 | 10 | Ambient |

| Oxy-Fuel Cutting | 6 | 7 | 15 | 200 |

| Traditional Cutting | 3 | 5 | 20 | Variable |

Thermohydraulic coating cutting presents various challenges that can impede efficiency and quality. One common issue is inconsistent cutting speeds, which can lead to uneven edges and increased material waste. To mitigate this, it's essential to calibrate the cutting equipment regularly and employ advanced sensors that monitor real-time performance. Utilizing programmable systems can help maintain uniform speeds across different materials, ensuring precision in every cut.

Another significant challenge is the accumulation of heat during the cutting process, which can affect the integrity of the thermohydraulic coating. To address this, integrating effective cooling systems or adopting techniques like water-mist cutting can significantly lower temperatures and reduce the risk of material degradation. Additionally, training personnel on best practices for machine operation can enhance cutting performance and extend the lifespan of the tools used. By proactively addressing these challenges, manufacturers can optimize their thermohydraulic coating cutting processes for superior results.

When optimizing thermohydraulic coating automatic cutting, measuring and evaluating results is crucial for achieving optimal performance. Accurate measurements help in understanding the efficacy of the cutting process, ensuring that the settings are perfectly tuned to handle the specific materials and thicknesses involved. Using calibrated instruments to assess thickness and cut quality will provide quantitative data that can identify areas for improvement.

Tips: Regularly check the calibration of your measuring tools to maintain precision. Implement a feedback loop where operators can report discrepancies in cut quality, aiding in continuous improvement initiatives.

Additionally, it's essential to evaluate the cutting parameters, such as speed and pressure, to establish a baseline for performance. Analyzing the data collected over time will reveal patterns that can inform adjustments to improve efficiency and reduce waste. The combined efforts of measurement and evaluation create a robust system, allowing for fine-tuning of the cutting process to meet the desired quality standards.

Tips: Utilize software that can analyze cutting data and provide insights into trends, enabling proactive adjustments. Encourage cross-departmental collaboration for a comprehensive evaluation of the cutting process, incorporating perspectives from production, quality control, and maintenance teams.