In the realm of modern manufacturing, the significance of a Cutting Machine cannot be overstated. As industries strive for increased efficiency and precision, the role of cutting machines has evolved to meet the demands of contemporary production lines. These machines are essential for achieving high-quality cuts in a variety of materials, including metals, plastics, and textiles, which directly influences the overall quality of the final product. Additionally, advancements in cutting technologies have streamlined production processes, reduced material waste, and improved safety for operators. Understanding how to effectively incorporate cutting machines into manufacturing operations is crucial for businesses aiming to enhance productivity and remain competitive in a fast-paced market. This article will explore the essential aspects of cutting machines, their applications, and the best practices for utilizing them effectively in modern manufacturing environments.

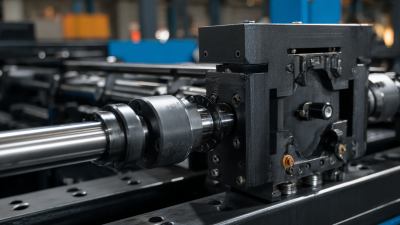

Cutting machines play a pivotal role in enhancing precision manufacturing by ensuring high levels of accuracy and consistency in production processes. These machines utilize advanced technologies such as laser cutting, waterjet cutting, and CNC machining, which allow manufacturers to create intricate designs and components with minimal margin for error. The precision achieved through these methods not only improves the quality of the final products but also optimizes material usage, reducing waste and lowering production costs.

Moreover, the integration of cutting machines in manufacturing workflows streamlines operations and increases efficiency. Automated cutting processes can operate continuously, significantly speeding up production times while maintaining high precision. This reliability is particularly beneficial in industries where tight tolerances are critical, such as aerospace, automotive, and medical device manufacturing. By enabling faster turnaround times and superior quality control, cutting machines have become indispensable tools in the modern manufacturing landscape.

Cutting machines play a vital role in modern manufacturing by significantly enhancing precision and efficiency. This chart illustrates the impact levels of various key factors influenced by cutting machines, highlighting their importance in the overall manufacturing process.

In modern manufacturing, advanced cutting technologies have become pivotal in streamlining production processes. According to a report by Technavio, the global cutting machine market is expected to grow by over 5% annually from 2021 to 2025, driven by the increasing demand for precision and efficiency. These machines are designed to provide superior cutting accuracy while minimizing material waste, which is crucial in a competitive landscape where manufacturers are under pressure to reduce costs and improve sustainability.

Furthermore, cutting machines equipped with automation features are enabling manufacturers to enhance productivity significantly. Industry data from Market Research Future indicates that automation in manufacturing can lead to an increase in output by up to 30% while reducing the operational costs by approximately 15%. Technologies such as CNC (Computer Numerical Control) and laser cutting systems allow for faster turnaround times and greater design flexibility, thereby supporting complex production requirements. As manufacturers continue to adopt these advanced cutting technologies, it becomes essential to recognize their role in not only improving operational efficiency but also in facilitating innovation across various sectors.

| Dimension | Description | Impact on Manufacturing |

|---|---|---|

| Precision | Ability to cut materials with high accuracy | Reduces waste and improves product quality |

| Speed | Faster cutting speeds compared to manual processes | Increases throughput and lowers production time |

| Material Versatility | Capability to cut various materials such as metal, wood, plastic | Expands product range and design possibilities |

| Automation | Integration with CNC and robotic systems | Reduces labor costs and enhances consistency |

| Safety | Advanced safety features in cutting machines | Minimizes workplace accidents and injuries |

| Cost Efficiency | Reduced scrap and optimized material usage | Lower operational costs and improved profitability |

In modern manufacturing, particularly within the textiles and apparel industries, cutting machines are vital for enhancing cost efficiency by reducing waste and labor costs. These machines employ advanced technologies such as laser cutting, which not only deliver high-speed and precise cuts but also minimize fabric waste. According to a recent review on sustainable machining, integrating technologies for optimized cutting processes can decrease operational waste by up to 30%, significantly contributing to environmental sustainability while enhancing profitability.

Moreover, the adoption of smart waste management systems in conjunction with cutting machines allows manufacturers to streamline their production lines. A case study highlights that implementing AI-driven technologies can reduce labor costs by automating routine tasks, resulting in up to 25% savings on labor expenditures. As the fashion industry pivot towards more sustainable practices, leveraging these cutting machines not only aligns with environmental goals but also addresses economic aspects by optimizing resource use and cutting down on unnecessary waste. With the potential to improve both sustainability and cost efficiency, cutting machines are integral to the future of modern manufacturing in textiles.

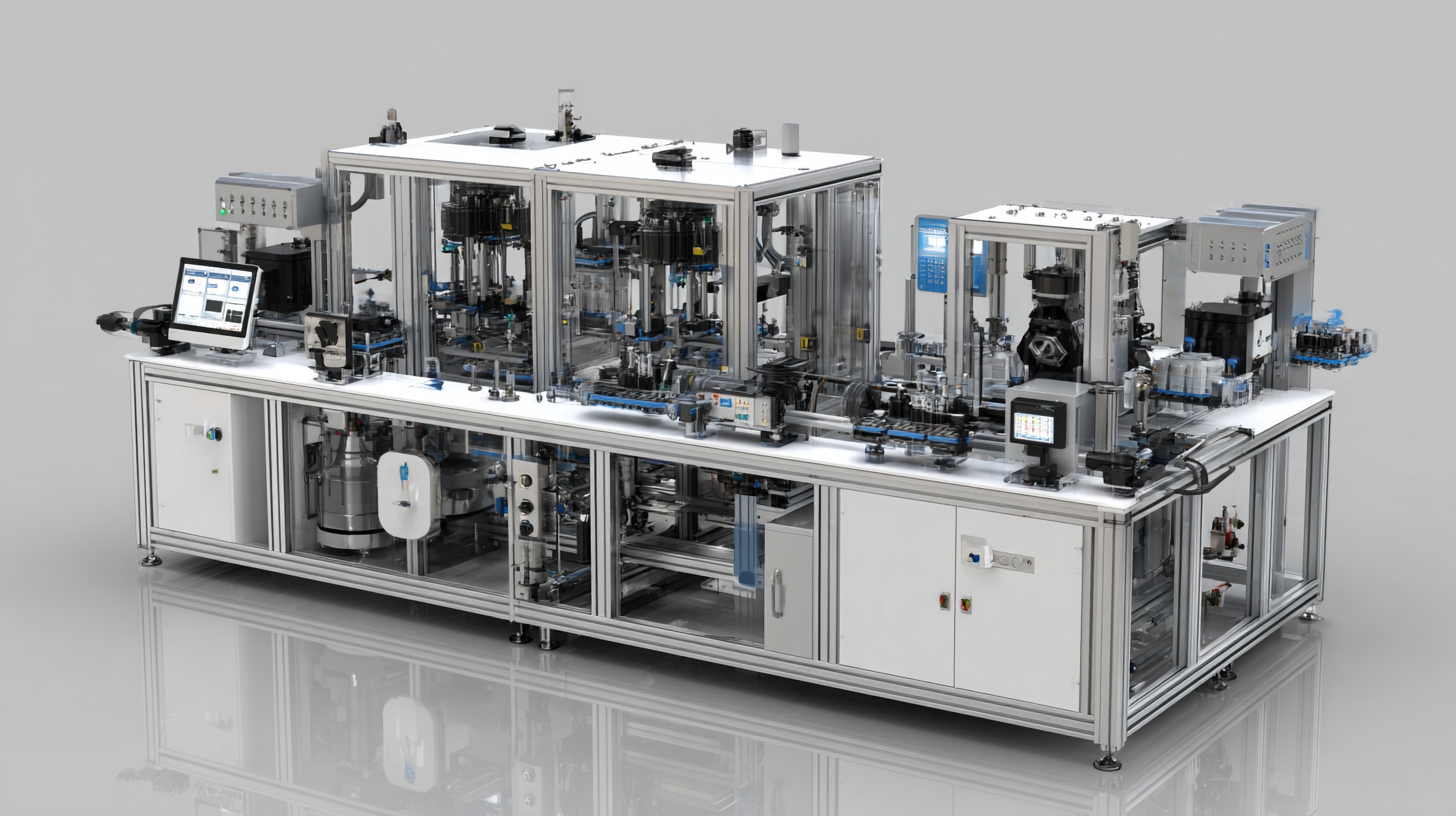

In modern manufacturing, the evolution of cutting machines has been pivotal in adapting to industry trends and enhancing operational efficiency. According to a report by MarketsandMarkets, the global cutting machine market is projected to reach $9.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.9%. This growth can be attributed to advancements in technology, particularly the integration of automation and precision engineering, which have transformed cutting machines from simple manual tools to sophisticated, high-speed devices capable of producing complex geometries with micron-level accuracy.

Furthermore, the increasing demand for customized products has necessitated the development of versatile cutting solutions. A study by Technavio highlights that the rise in automation in manufacturing processes is a key driver, with automated cutting machines leading to a 30% reduction in operational costs while improving production speed. Moreover, sustainability trends in the industry have sparked innovations in cutting technology, enabling manufacturers to minimize waste and enhance material utilization, thus adhering to regulatory standards while maintaining profitability. These developments illustrate how cutting machines have evolved and continue to play a critical role in shaping the future of manufacturing.

The evolution of cutting machines marks a significant advancement in modern manufacturing, driven by the integration of cutting-edge technologies. Future innovations promise to enhance precision and efficiency, paving the way for smarter manufacturing processes. For instance, the adoption of artificial intelligence and machine learning is set to optimize cutting patterns, reduce waste, and streamline operations. These intelligent systems will analyze data in real-time, allowing manufacturers to adjust their strategies dynamically based on production requirements.

Another promising trend is the incorporation of advanced materials and robotics. Next-generation cutting machines will likely utilize durable, lightweight materials that improve performance while minimizing energy consumption. Furthermore, robotic automation will enable high-speed, precise cutting operations with minimal human intervention. This synergy between robotics and smart technologies not only improves productivity but also enhances workplace safety as hazardous tasks become automated. As manufacturers embrace these innovations, the landscape of production will continue to evolve, driving competitiveness and sustainability in the industry.