In modern manufacturing environments, efficiency and precision are paramount, and the Hydraulic Cutting Press has emerged as a pivotal tool in streamlining production processes. According to a report by Industry Research, the global hydraulic press machine market is projected to reach $5.22 billion by 2026, driven by increasing automation and demand for high-quality finished products across various sectors, including automotive, aerospace, and metal fabrication. This growth underscores the importance of understanding and effectively utilizing hydraulic cutting presses to enhance operational effectiveness and maintain a competitive edge.

As manufacturers increasingly adopt advanced technologies, it becomes essential to harness the capabilities of hydraulic cutting presses. These machines provide numerous advantages, including their ability to deliver consistent pressure and cut through thick materials with precision, making them ideal for various applications such as shearing, blanking, and forming. Reports indicate that optimizing the use of hydraulic cutting presses can lead to a significant reduction in production costs while improving product quality, with some manufacturers reporting up to a 30% increase in efficiency when these machines are utilized correctly.

To fully leverage the potential of hydraulic cutting presses, it is crucial for production teams to implement best practices and understand the intricacies of the equipment. This article aims to provide top tips for effectively incorporating hydraulic cutting presses into your production process, ensuring that manufacturers can achieve their operational goals while adapting to the evolving landscape of modern manufacturing.

Hydraulic cutting presses are essential machines that harness the power of hydraulic fluid to generate high pressure, enabling precise cutting of various materials. These tools operate through a straightforward mechanism where fluid is pumped into a cylinder, creating a force that drives a cutting blade down onto the material. This method of cutting is particularly effective for metals, plastics, and composites, providing clean edges and reducing the need for secondary finishing processes. Understanding the operational principles of hydraulic cutting presses is vital for maximizing their efficiency and ensuring safety during use.

The versatility of hydraulic cutting presses makes them suitable for a range of production environments. They can be adjusted to accommodate different cutting speeds and pressures, making it easier to customize operations based on material type and thickness. Furthermore, these presses are designed to handle large batches of material, allowing for high-volume production runs while maintaining consistent quality. Knowledge of the various settings and capabilities of a hydraulic cutting press can dramatically enhance productivity and material yield, leading to improved overall efficiency in the production process.

Hydraulic cutting presses have become an indispensable tool in modern manufacturing due to their ability to enhance efficiency and precision in various production processes. One of the key benefits of these machines is their capacity for high force output, which allows for the effective cutting of materials, even those that are particularly thick or tough. This capability not only speeds up the manufacturing process but also reduces the need for multiple machines, consolidating production steps and streamlining operations.

Additionally, hydraulic cutting presses offer automation features that further improve manufacturing efficiency. With programmable controls, operators can easily adjust settings for different materials and cutting specifications, ensuring consistent quality and reducing the risk of human error. This level of precision not only saves time during production but also minimizes material waste, leading to cost savings in the long run. Overall, the integration of hydraulic cutting presses into manufacturing processes can significantly boost productivity while maintaining high standards of quality.

| Tip | Benefit | Impact on Efficiency |

|---|---|---|

| Regular Maintenance | Increased Reliability | Reduces downtime by up to 30% |

| Proper Training for Operators | Enhanced Safety | Decreases accidents by 50% |

| Optimizing Cutting Parameters | Improved Cuts Quality | Increases material yield by 20% |

| Implementing Automation | Reduced Labor Costs | Boosts production speed by 40% |

| Using Quality Hydraulic Fluids | Extended Equipment Life | Lowers maintenance costs by 25% |

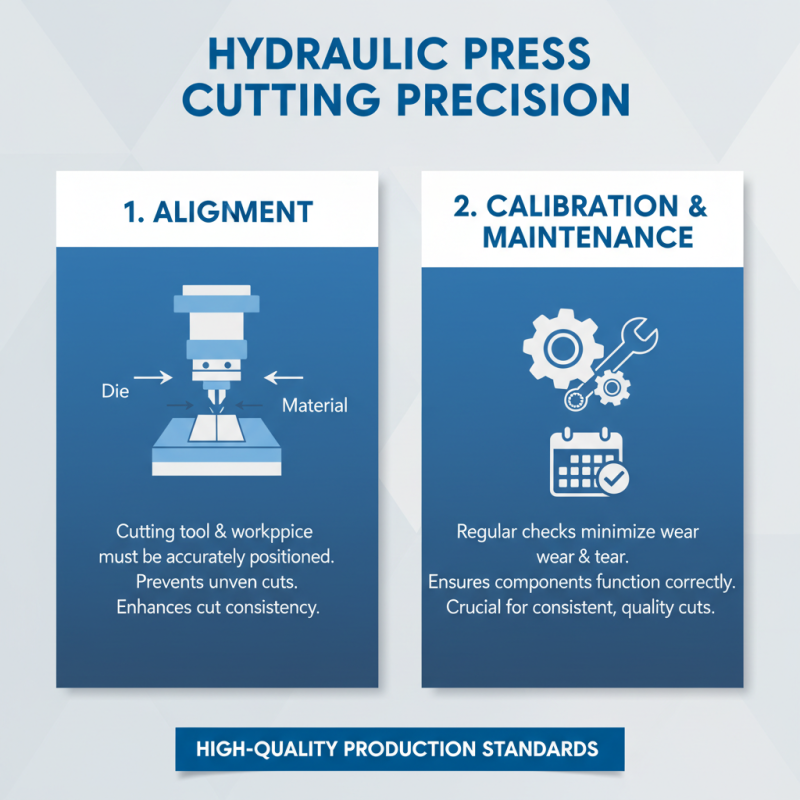

When using hydraulic cutting presses, several factors significantly influence cutting precision, crucial for maintaining high-quality production standards. One critical aspect is the alignment of the cutting tool and the workpiece. Misalignment can lead to uneven cuts, which compromises the integrity of the finished product. Ensuring that the dies and the material are accurately positioned can drastically enhance the consistency of each cut. Regular calibration and maintenance of the hydraulic press also help in achieving precise cuts by minimizing wear and tear on the components involved in the cutting process.

Another essential factor is the appropriate selection of cutting parameters, including pressure, speed, and timing. Each material handles these conditions differently; for instance, softer materials may not require as much pressure as harder substrates. Tailoring these settings to match the specific material type can prevent issues such as deformation or excessive burr formation. Moreover, monitoring the hydraulic fluid levels and temperatures is vital, as these can affect the performance of the press and, ultimately, the precision of the cuts. An understanding of these critical factors will help operators enhance their cutting operations, leading to improved efficiency and product quality.

When operating hydraulic cutting presses, safety should always be the top priority. Adhering to established safety standards is critical to ensure a secure working environment. Operators must wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection, to shield themselves from potential hazards such as flying debris and noise. Additionally, regular maintenance of the equipment is essential to prevent malfunctions that could lead to accidents. Operators should be trained in both the operation of the hydraulic press and in emergency procedures, allowing them to respond effectively in the case of an incident.

Best practices for hydraulic press usage also hinge on maintaining clear communication in the workplace. Designated signals should be established for operators and nearby workers to enhance coordination during operation. It is advisable to conduct regular safety drills and refresher training to keep safety protocols fresh in the minds of all team members. Furthermore, ensuring that the workspace is free of clutter and that appropriate safety barriers are in place can significantly reduce the risk of injury. By prioritizing safety standards and implementing best practices, organizations can foster a culture of safety while maximizing efficiency in their production processes.

This bar chart illustrates the common safety standards and best practices for hydraulic press usage, highlighting the importance of each guideline based on industry feedback.

To ensure the longevity and efficiency of hydraulic cutting presses in your production process, regular maintenance is paramount. Begin by conducting routine inspections of the hydraulic fluid levels and conditions.

Contaminated or low hydraulic fluid can lead to decreased performance and potential damage to the system. It is essential to replace the fluid periodically based on the manufacturer's recommendations and to use the appropriate type specified for your equipment.

Additionally, pay attention to the seals and hoses, as they are critical components that can wear down over time. Inspect for any signs of leakage or damage, and replace them as necessary to avoid operational interruptions. Regularly cleaning the cutting area and removing any debris will not only enhance the precision of cuts but also contribute to the overall maintenance of the machine.

Implementing a lubrication schedule for moving parts is also beneficial, as it helps reduce friction and wear, ensuring smoother operation and extending the lifespan of hydraulic cutting presses.