The manufacturing landscape is evolving rapidly, and precision engineering is at the forefront of this transformation. Among the key tools driving this evolution is the Die Cutting Press, which has become essential for industries demanding high accuracy and repeatability in production.

According to a recent industry report by Smith & Associates, the global die cutting press market is projected to grow from $1.5 billion in 2022 to $2.3 billion by 2028, reflecting a CAGR of 7.5%. This growth underscores the critical role that die cutting technology plays in optimizing operational efficiency and fulfilling the growing demands of modern manufacturing.

Experts in the field emphasize the importance of this technology for manufacturers looking to achieve superior precision in their processes. Dr. Jennifer Lee, a renowned industry analyst and author of the report "Future Technologies in Manufacturing," stated, "The Die Cutting Press is not just a tool; it is a vital component in the quest for precision and quality that modern manufacturers are striving to attain." This insight resonates with manufacturers who are increasingly investing in advanced die cutting solutions to enhance their production capabilities and remain competitive in a dynamic market environment. As the demand for precision products continues to rise, the Die Cutting Press will undoubtedly be a cornerstone of growth in the precision manufacturing sector.

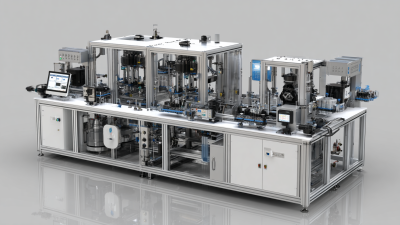

The die cutting press plays a crucial role in enhancing precision manufacturing techniques, particularly in sectors that demand high levels of accuracy and efficiency. As industries increasingly adopt digital manufacturing technologies, productivity has seen significant improvements. For instance, the global die cutting market is experiencing changes that reflect a growing emphasis on speed and quality, with companies striving to produce intricate designs with reduced turnaround times. The ongoing advancements in die cutting processes allow for complex shapes and precise cuts, essential for maintaining competitive advantage.

Furthermore, the comparative study of advanced machining methods, such as ultrasonic and laser-assisted techniques for sustainable leather cutting, highlights how modern equipment is instrumental in promoting greener industrial practices. With the leather industry focusing on sustainable production strategies, incorporating precision tools like die cutting presses can minimize waste and maximize material utilization. The tooling market is projected to witness continued growth, with increasing demands for dies and molds segment, which further illustrates the significance of die cutting technology in achieving enhanced manufacturing outcomes while addressing environmental concerns.

Die cutting presses are becoming increasingly pivotal in meeting the precise demands of modern manufacturing. With the global die cutting machine market projected to reach USD 3.4 billion by 2027, the technology is rapidly evolving to accommodate various materials and intricate designs. One of the key advantages of die cutting presses is their ability to produce high volumes of consistent, accurate parts, which are essential in industries like packaging, automotive, and electronics. According to a report by MarketsandMarkets, the demand for die cutting presses has been driven by the growing need for precision-engineered components and the adherence to quality standards.

Furthermore, die cutting presses offer manufacturers enhanced flexibility. They can work with an array of materials — from thin films to heavy-duty cardboard — making them ideal for diverse applications. This versatility is crucial in an era of customized production that necessitates quick turnarounds and adaptability. Industry data suggests that manufacturers leveraging die cutting technology can experience production efficiency improvements of up to 30%.

**Tips for Maximizing Die Cutting Efficiency:**

1. Regular maintenance of your die cutting press can prevent downtime and prolong its lifespan, ensuring consistent performance.

2. Investing in high-quality dies and materials can significantly enhance the precision and quality of final products.

3. Stay updated on technological advancements in die cutting to continuously improve manufacturing processes and remain competitive in the market.

Die cutting presses have become instrumental in driving innovation across various industries by providing precise cutting solutions that enhance productivity and reduce waste. According to a market research report by Research and Markets, the global die cutting machine market is projected to reach USD 4.5 billion by 2026, with a CAGR of 5.8% from 2021 to 2026. This growth underscores the increasing adoption of die cutting technology in sectors like packaging, textiles, and automotive manufacturing. In packaging, for instance, die cutting allows for the creation of unique shapes and designs that cater to consumer preferences, leading to improved product presentation and increased sales.

In the textile industry, die cutting presses are utilized for cutting fabrics into intricate patterns and shapes, which are essential for fashion design and clothing manufacturing. A report from Mordor Intelligence highlights that the textile die cutting machinery market is expected to grow at a CAGR of 4.2% over the next five years. This growth is fueled by the demand for customization and the need for manufacturers to keep up with rapidly changing fashion trends. Similarly, in the automotive sector, die cutting is employed to produce components with high precision, ensuring quality and reducing production times. As industries continue to evolve, the innovative applications of die cutting presses will undoubtedly play a crucial role in shaping manufacturing processes and improving overall efficiency.

| Industry | Die Cutting Application | Precision Achieved (%) | Production Rate (Units/hour) | Cost Reduction (%) |

|---|---|---|---|---|

| Automotive | Gaskets and Seals | 98% | 1200 | 15% |

| Packaging | Custom Boxes | 95% | 2000 | 20% |

| Textiles | Fabrics Cutting | 97% | 800 | 10% |

| Electronics | Circuit Board Components | 99% | 1500 | 12% |

| Construction | Insulation Materials | 96% | 600 | 18% |

Die cutting technology is rapidly evolving, driven by advancements in automation, materials science, and software integration. As manufacturers increasingly seek precision and efficiency, trends such as the implementation of smart die cutting machines are becoming prevalent. These machines, equipped with sensors and IoT capabilities, enable real-time monitoring of the cutting process, ensuring higher accuracy and reduced waste. Moreover, the integration of artificial intelligence allows for predictive maintenance, which minimizes downtime and enhances production reliability.

Another significant trend is the diversification of materials used in die cutting. With the rise of sustainable practices, manufacturers are now focusing on eco-friendly materials, such as biodegradable plastics and recycled substrates. This shift not only meets consumer demand for sustainable products but also opens new markets and applications for precision manufacturing. Additionally, advancements in digital die cutting enable greater flexibility, allowing manufacturers to produce custom designs efficiently, thereby adapting quickly to market changes and customer specifications. These innovations collectively position die cutting as a critical component of the future landscape of precision manufacturing.

Integrating die cutting presses into lean manufacturing practices significantly enhances operational efficiency and precision. According to a report by Market Research Future, the die cutting machine market is expected to reach USD 10 billion by 2023, fueled by the increasing demand for customized components across various industries. Lean manufacturing emphasizes waste reduction and optimization of processes; die cutting presses seamlessly align with these objectives by enabling highly accurate cuts with minimal material waste.

Moreover, implementing die cutting technology can lead to shorter production times and improved workflow. A study from the National Institute of Standards and Technology (NIST) highlights that lean practices can reduce operational costs by up to 30%. By automating cutting processes and standardizing production methods, manufacturers can not only enhance output but also maintain high quality in their products. This evolution towards integrating die cutting presses within lean frameworks positions companies to respond more swiftly to market demands, thus driving precision manufacturing growth and sustaining competitive advantage in an ever-changing industry landscape.