When selecting a Coating Lamination Machine, businesses face critical decisions. The global market for lamination machines is projected to grow substantially. According to industry reports, demand is expected to rise by over 5% annually. This increase signals a broader need for efficient, high-quality surface finishing solutions.

Choosing the right machine is not straightforward. Various factors come into play, such as production volume and material compatibility. For instance, businesses must evaluate the types of substrates they will laminate. Issues may arise if the selected machine cannot handle these materials effectively.

Investing in the wrong Coating Lamination Machine can lead to increased costs and reduced productivity. Companies may end up overspending on features they do not need. Therefore, thorough research and consultation with experts can prove essential. Understanding the specific needs of your operation will guide you in making the right choice.

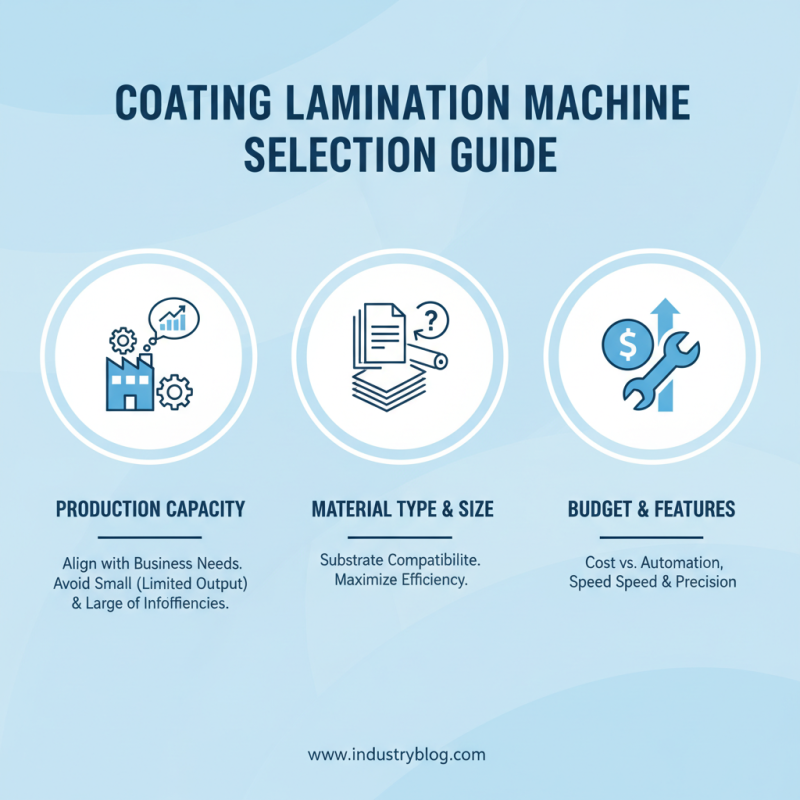

When choosing a coating lamination machine, you need to weigh several factors carefully. First, consider the production capacity. It should align with your business needs. A machine that is too small may limit your output. Conversely, a massive machine can lead to inefficiencies if you don’t have the volume to justify it.

Quality is an essential aspect. Look for machines that ensure consistent lamination quality. Inconsistent results can damage your reputation. It's often hard to gauge quality upfront. Investigate reviews and testimonials from other users. This can provide insights into real performance levels.

Tips: Always test the machine before purchasing. If possible, run trial samples. This will help you understand how it operates. Also, consider the size of the machine. It should fit your workspace without crowding. Sometimes, a compact design can be more efficient.

Another critical factor is the ease of use. Operators must feel comfortable with the machine. Complicated setups can lead to mistakes. Ensure that the manufacturer offers proper training. It’s essential for maintaining productivity. You might need technical support down the line. Consider the availability of spare parts too. This can be a long-term concern that impacts your operations.

When choosing a coating lamination machine, understanding the types available is crucial. There are several key types. Each type serves different purposes. Some machines are designed for thin films, while others can handle thicker materials.

For instance, a cold lamination machine is ideal for sensitive documents. It protects against moisture and UV light. However, it may not provide the same durability as hot lamination. Hot lamination machines create a stronger seal but can damage heat-sensitive materials. Finding the right balance is essential for your specific needs.

Another consideration is the scale of your production. Smaller units may be sufficient for low-volume tasks. Yet, as your business grows, investing in industrial machines might be necessary. Larger machines increase efficiency but require more floor space. Reflect on your current and future needs. This thought process will help avoid costly mistakes.

When selecting a coating lamination machine, production capacity and speed are crucial factors. Analyzing your output needs is essential. What volume do you aim to produce? Understanding this will help identify the right machine specifications for your business.

Speed is equally important. Different machines operate at various speeds. Some may be faster, while others focus on precision. You might find that choosing a faster option improves efficiency but risks quality. Achieving a balance can be challenging. Sometimes, a slower machine delivers a better finish.

Consider future growth as well. If you anticipate increased demand, opt for a machine that can scale with your business. This foresight can save time and money down the line. Evaluating these elements requires careful thought. Mistakes in this area can lead to costly adjustments later on. Assess your requirements carefully to avoid regrets.

| Machine Type | Maximum Speed (m/min) | Production Capacity (sqm/hr) | Material Compatibility | Price Range (USD) |

|---|---|---|---|---|

| Roll-to-Roll Laminator | 20 | 150 | Paper, Plastic | $15,000 - $25,000 |

| Flatbed Laminator | 10 | 100 | Cardstock, Vinyl | $20,000 - $35,000 |

| Sheet Laminator | 15 | 120 | Paper, Photographic Material | $10,000 - $18,000 |

| Thermal Laminator | 12 | 110 | Paper, PVC | $8,000 - $15,000 |

| Cold Laminator | 8 | 80 | Paper, Canvas | $5,000 - $12,000 |

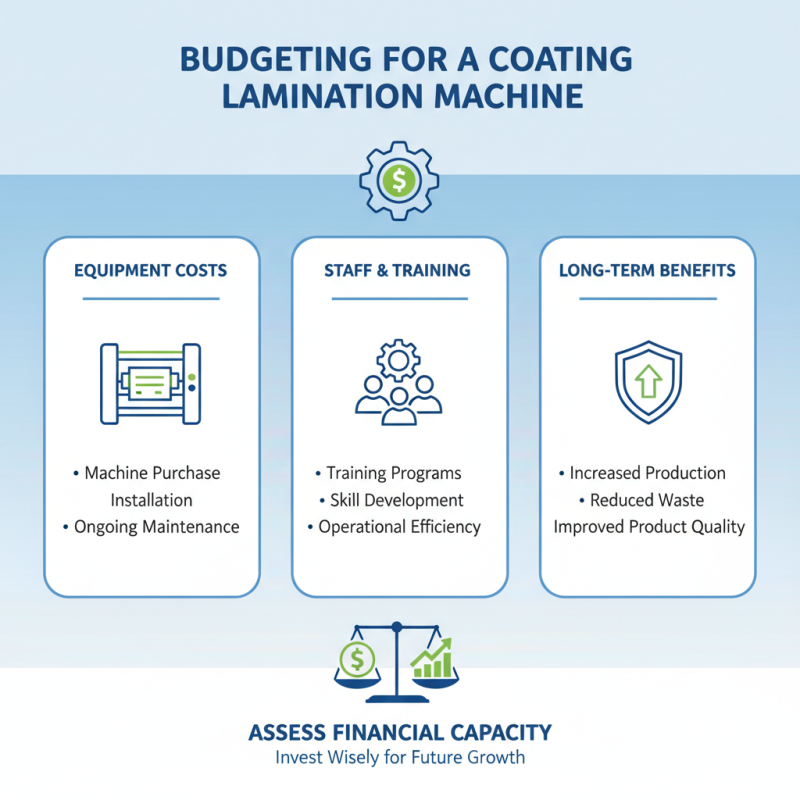

When budgeting for a coating lamination machine, understanding your financial capacity is crucial. Start by assessing the overall costs related to the equipment. These include the machine itself, installation, and ongoing maintenance. Don’t forget the cost of training for staff to use it effectively. This investment can have long-term benefits, but it's essential to weigh these against your current financial health.

Consider the features you truly need. Some machines come with advanced capabilities that might not be necessary for your operations. Reflect on your production volume and the types of materials you use. Sometimes, rather than the most high-tech option, a more basic model could meet your requirements adequately and save you money. It's easy to get caught up in the latest technology; however, practicality should guide your choices.

Look for hidden costs too. Supplies for the machine, energy consumption, and spare parts can add up quickly. These variables require careful consideration. You might find that a "bargain" machine leads to unexpected expenses that eclipse its initial savings. While it’s tempting to make a quick decision, taking the time to research and plan your budget can prevent costly mistakes down the line.

Maintaining a coating lamination machine is crucial for its longevity. Regular inspection is essential. Check for wear and tear on parts. Small issues can lead to larger problems. Don't ignore unusual noises or vibrations. Address these immediately to avoid costly repairs later.

Tip: Develop a routine maintenance checklist. This should include daily, weekly, and monthly tasks. Keeping track of these can help prevent unexpected downtime. Document any issues that arise. Understanding the history of repairs can aid future maintenance decisions.

Support is another vital aspect to consider. Ensure you have access to technical assistance when needed. Delays in support can derail production schedules. Evaluate the response time of potential support teams. This can be a game-changer during emergencies.

Tip: Consider training your staff on basic troubleshooting. Empowering them can expedite solutions and minimize disruptions. However, remember that some problems require professional attention. Knowing when to call for help is important. Recognize that not every issue can be solved in-house.