Choosing the right Manual Cutting Machine can be challenging. With many options available, it’s easy to feel overwhelmed. A manual cutting machine is essential for various tasks, from crafting to industrial applications. However, the needs of each user can differ significantly.

Consider the material you'll often cut. Some machines handle paper, while others manage thick substances like wood or metal. Think about the size too. A larger machine may be necessary for extensive projects, but a compact design could save space and enhance portability.

Don’t forget about user-friendliness. A machine that’s complex could waste time and frustrate you. Check user reviews and seek machines praised for their ease of use. Reflect on your cutting needs and preferences. A poorly chosen manual cutting machine can lead to inefficiency and disappointment. Keep your specific requirements in mind when making your decision.

When choosing a manual cutting machine, it’s important to understand the different types available. Each type has its unique features and specific uses. For example, rotary cutters are great for precise cuts on fabric. They glide smoothly and require a cutting mat for safety. Users often enjoy how easy they are to handle, but they must stay sharp for effective cutting.

Another option is the straight edge cutter. This machine is perfect for cutting straight lines in various materials. It typically comes with a ruler guide, allowing for accuracy. However, some users find it challenging to maintain consistency. If you're not careful, uneven cuts can result, which can be frustrating in projects requiring precision.

Lastly, there are handheld cutters, which offer flexibility and portability. They are often lighter but may lack the stability of other machines. Users sometimes struggle with fatigue during prolonged use. Each type has its pros and cons, and selecting the right one often calls for reflection on personal cutting habits and project requirements.

When choosing a manual cutting machine, several key factors come into play. Each factor can significantly influence the efficiency and quality of your work. The machine's cutting capacity should align with your project needs. According to industry reports, machines with a cutting width of at least 24 inches cater to most small to medium-sized projects effectively.

Durability is another vital aspect. Some machines use materials that wear out quickly. Look for those crafted from sturdy metal components to ensure longevity. Maintenance can be tedious but is necessary for optimal performance. Lack of maintenance can lead to decreased accuracy over time.

Tips:

1. Always check user reviews before making a choice.

2. Consider the weight of the machine. A lighter model could offer better portability.

3. Don't underestimate the importance of proper safety features.

Functionality is crucial. Can you adjust the cutting depth easily? Look for models that provide convenient adjustments. A complicated setup can hinder workflow. Analyze whether the machine fits comfortably in your workspace. Poor planning can lead to accidents or inefficiencies. Investing time in selecting the right machine pays off in the long run.

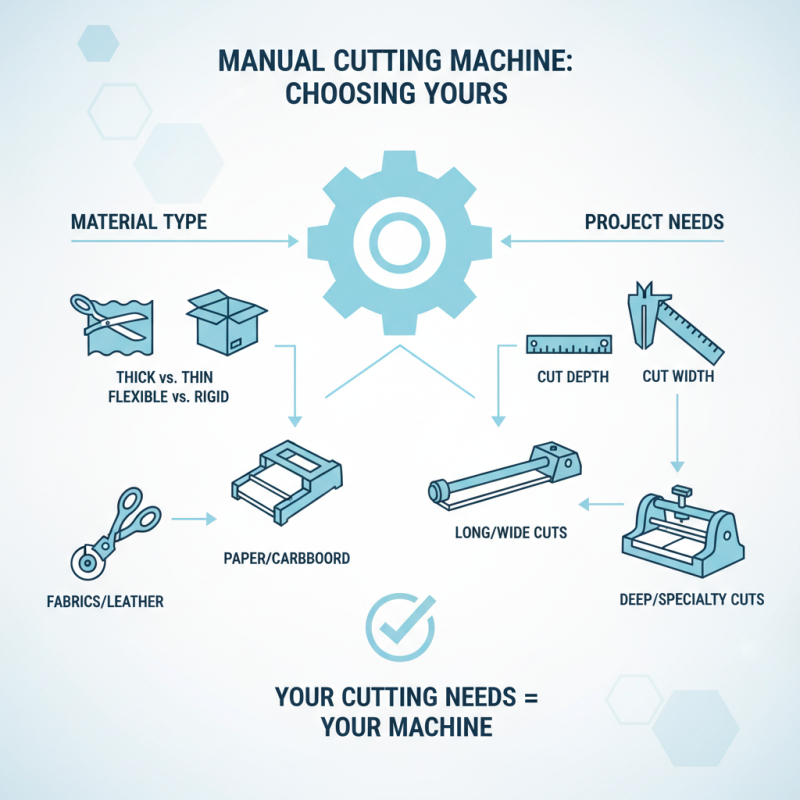

When choosing a manual cutting machine, consider your specific cutting needs and the materials you'll work with. Think about the types of materials: are they thick or thin? Are they flexible or rigid? Your answers shape the machine you need. Heavy fabrics need different blades than paper or cardboard. Assess the cutting depth and width required for your projects.

Tips: Test machines in-store if possible. Look for adjustable options. They offer flexibility for various tasks.

Some machines handle intricate designs better than others. If precision is key, ensure the machine offers fine adjustments. Think about your workspace too. A compact machine is great for small spaces, but larger machines often provide better cutting power. Reflect on your future needs. You may want to expand your projects over time.

Tips: Keep an eye on durability. Some machines might start strong but wear out quickly. Read reviews to gauge long-term performance.

When selecting a manual cutting machine, features and specifications play a crucial role. You should consider cutting capacity, blade types, and ergonomics. A good machine must accommodate the materials you’ll work with. For instance, if you cut thick fabrics, a robust blade is essential. If you handle delicate materials, a fine, sharp blade will do better.

Pay attention to the machine's weight and portability. Heavier machines often provide stability, but they can be cumbersome. Lightweight options offer ease of transport, but may sacrifice some functionality. It’s essential to find the right balance between portability and performance. User-friendliness is also a key factor. Some models may have complex settings that can lead to frustration.

Another aspect worth exploring is maintenance. Regular upkeep can prolong the life of a cutting machine. Some models are easier to maintain than others, which is an important consideration. Keep in mind that no machine is perfect. Each has its strengths and weaknesses. Ultimately, it’s about what best fits your specific cutting needs.

| Model | Cutting Width | Cutting Depth | Weight | Material Compatibility | User Rating |

|---|---|---|---|---|---|

| Model A | 24 inches | 0.5 inches | 15 lbs | Paper, Cardstock | 4.5/5 |

| Model B | 36 inches | 1 inch | 20 lbs | Fabric, Vinyl | 4.7/5 |

| Model C | 12 inches | 0.25 inches | 10 lbs | Paper, Film | 4.3/5 |

| Model D | 30 inches | 0.75 inches | 22 lbs | Paper, Cardstock, Thin Wood | 4.6/5 |

When budgeting for a manual cutting machine, consider your needs. Analyze what materials you will cut. Look for features that suit your specific projects. A basic model might suffice for occasional use. However, frequent users may require additional features. Decide on a price range before you start exploring options.

Sourcing the best deals can be tricky. Online marketplaces often offer competitive prices. Compare multiple listings to get a fair idea of cost. Local hardware stores might have different pricing strategies. Sometimes, clearance sales can yield great finds. Don't rush into a purchase; take your time to evaluate.

Reflect on potential hidden costs. Accessories, maintenance, and replacement parts may add up. Always inquire about warranty options. These factors can influence your overall budget. Make notes as you shop to identify what truly meets your needs. Balancing quality and price is crucial in the decision-making process.

This bar chart compares the prices of manual cutting machines based on different features. Use it to identify the best options within your budget when choosing the right manual cutting machine.