In the rapidly evolving field of *Thermohydraulic Coating Automatic Cutting*, innovations are set to reshape industry standards by 2026. Expert Dr. Emily Cheng, a leader in this domain, remarked, "The future of cutting technology lies in precise control and eco-friendly coatings." This statement highlights the significance of integrating sustainability with advanced cutting techniques.

Technological advancements allow for enhanced efficiency and precision in thermohydraulic processes. Companies are investing in automated solutions that reduce waste and improve output quality. The amalgamation of thermohydraulic coatings with automatic cutting machines presents exciting opportunities. However, there exists a challenge. Many firms struggle with the adaptation of these new technologies, creating a gap between innovation and implementation.

As we look toward 2026, it is crucial to reflect on the balance between progress and practicality. The quest for the best solutions often reveals unforeseen obstacles. Companies must strive for consistent improvements. By embracing innovative cutting technologies, the industry can redefine standards while addressing the complexities involved. These reflections pave the way for a future where *Thermohydraulic Coating Automatic Cutting* stands at the forefront of manufacturing excellence.

Thermohydraulic coatings are innovative materials that enhance thermal and hydraulic performance. They are applied to various surfaces, improving efficiency in different sectors. These coatings possess unique properties, making them ideal for applications in automotive, aerospace, and manufacturing.

In automotive applications, thermohydraulic coatings reduce engine heat and friction. This results in improved performance and fuel efficiency. In manufacturing, they help to minimize downtime by protecting tools from wear and tear. However, the process of applying these coatings can be challenging. Ensuring uniform application is vital for effectiveness.

While the advantages are clear, not all coatings work seamlessly. Some may peel or degrade under extreme conditions. This raises questions about material selection and long-term reliability. Continuous research is essential to find solutions that can maximize their performance across all applications.

The landscape of automatic cutting technologies is transforming, especially for thermohydraulic coatings. Innovations promise faster and more precise methods. By integrating advanced robotics, companies are enhancing operational efficiency.

New cutting systems leverage high-precision lasers. These lasers reduce material waste, which is essential in today's eco-conscious market. However, the initial setup can be complex. Workers need extensive training to operate these machines effectively. This hurdle presents a challenge for companies wishing to adopt new technologies swiftly.

Another remarkable innovation is the use of AI in cutting processes. AI algorithms analyze coating types and recommend optimal cutting strategies. This advancement can lead to enhanced quality control. Yet, reliance on technology may introduce risks. Human oversight remains crucial to ensure the system performs as expected. Continuous evaluation of these innovations is necessary for balancing efficiency and reliability.

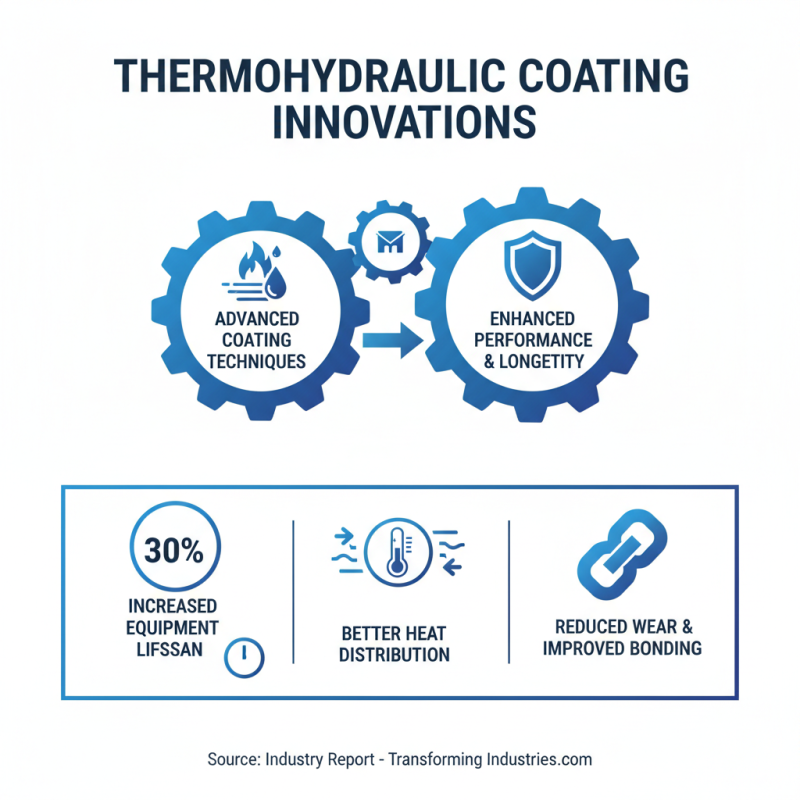

Advanced thermohydraulic coating techniques have transformed multiple industries by enhancing performance and longevity. According to a recent industry report, these innovations can increase equipment lifespan by up to 30%. This significant improvement results from advanced bonding mechanisms that ensure better heat distribution and reduced wear.

One of the key benefits of these coatings is their ability to withstand extreme temperatures and corrosive environments. High-performance thermohydraulic coatings can operate effectively at temperatures exceeding 600°F. This capability reduces the risk of failure in critical operations. Equipment with these coatings show a 50% reduction in maintenance costs, making them a wise investment.

Tip: Regular inspections are crucial. Sometimes, even the best coatings can wear down over time. Watch for signs of degradation early to avoid costly downtime.

These techniques also support environmental sustainability. By enhancing efficiency, they reduce energy consumption. However, the application process can be complex. Improper techniques can lead to poor performance or even product failure. Organizations must invest in training and quality assurance to ensure successful implementation.

Tip: Always seek expert advice. A small mistake in the application can lead to significant issues later.

As we look toward the future of thermohydraulic coating and cutting automation, several trends are emerging. Analysts predict that the market for automated systems will grow significantly. By 2025, the industry is expected to reach 15 billion dollars. This growth largely stems from the demand for precision and efficiency in manufacturing. Companies are increasingly seeking to reduce waste and enhance production rates.

Advancements in robotics play a crucial role in this evolution. Integrating AI algorithms with thermohydraulic systems can optimize cutting processes. Processes that once required hours may only take minutes. However, achieving seamless integration poses challenges. It requires not only technological innovation but also worker training and adjustment to new systems. A recent study highlighted that 30% of workers felt unprepared for rapid technological shifts.

In addition, sustainability is a driving force. Consumers are keen on eco-friendly practices. A report indicated that 70% of manufacturers are shifting toward greener processes. Innovations in thermohydraulic coatings must align with this environmental consciousness. While it's a step forward, the industry must reflect on balancing efficiency with sustainability. Greener practices often lead to higher upfront costs, which can impact profit margins.

| Innovation Type | Key Features | Efficiency Improvement (%) | Expected Market Growth (2026) |

|---|---|---|---|

| Automated Coating Application | Precision control, reduced waste, faster application | 30% | 15% |

| Robotic Cutting Systems | High-speed operation, multi-material compatibility, adaptive cutting paths | 25% | 20% |

| Smart Integration Technology | IoT connectivity, real-time monitoring, data-driven optimizations | 35% | 18% |

| Eco-Friendly Coating Solutions | Non-toxic materials, reduced environmental impact | 40% | 25% |

| Adaptive Cutting Technology | Machine learning algorithms to optimize cutting processes | 20% | 22% |

The adoption of thermohydraulic coatings in manufacturing has shown significant advancements. In the automotive industry, a study indicated that these coatings reduce wear by up to 30%. Implementations have improved energy efficiency, a key concern for manufacturers. However, challenges remain. Not every factory has access to cutting-edge technology. The initial investment can be prohibitive.

In the aerospace sector, case studies revealed a 15% reduction in maintenance costs due to thermohydraulic coatings. These coatings enhance performance at high temperatures. Yet, data from recent evaluations highlight inconsistencies in application processes. Some manufacturers reported uneven thickness, which led to performance variability. This showcases the need for better training and more refined application methods.

Exploring the food packaging industry reveals varied results. Certain implementations have boosted shelf life, impressively extending it by 20%. However, inconsistent results across different materials raise concerns. Reports cited failures in certain environmental conditions. The need for standardized testing and quality control is evident. While the innovations are promising, the journey requires careful navigation.