automatic impregnating lamination machine description

Kuntai Group

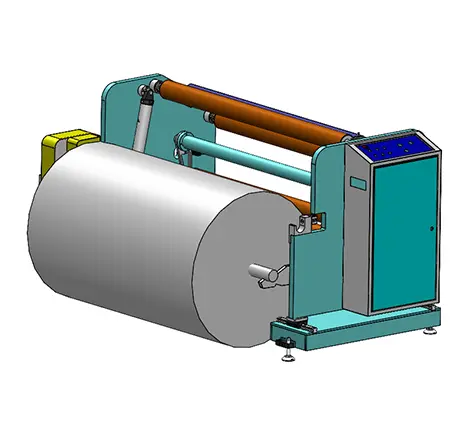

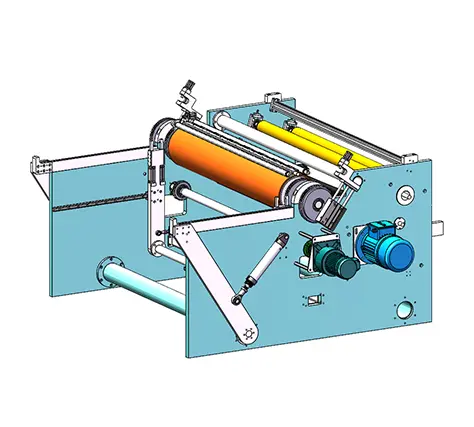

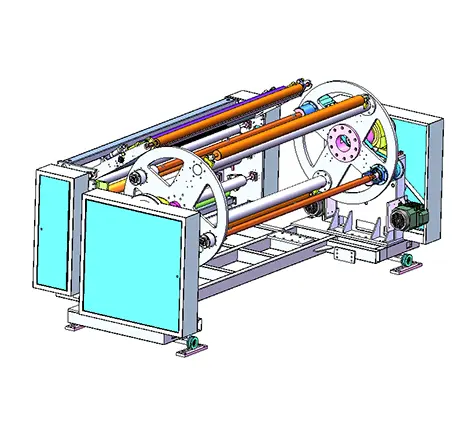

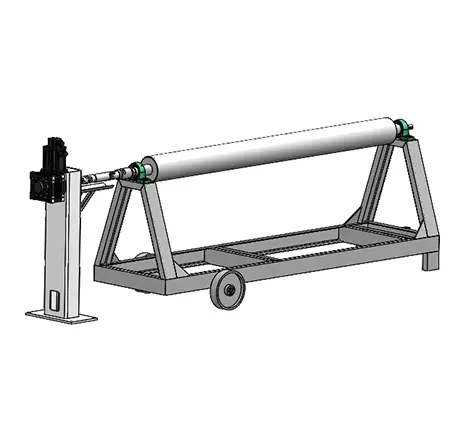

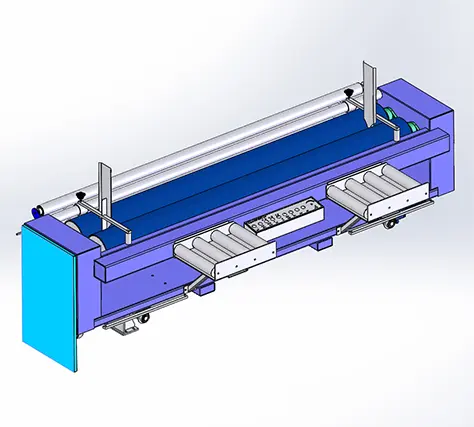

Place the fiber bobbins on the rack, unwind and feed to the cluster device and arrange fibers in parallel. Then parallel them after the cluster pass through the finishing device to form the parallel and closely packed filament bundles. After the spreading of the fibres, add tension to ensure the smoothness of the fibres. After impregnating the fiber with resin or adhesive, laminating the carrier membrane through the uniform filament bundle after the adhesive device. Afterwards, the heat roller evaporates resin solvent and curing, forming the unidirectional fabric.

Apart from impregnating fibres, people also impregnating fabrics, thus Kuntai also designs and manufactures various fabric impregnating machines for various industries.

automatic impregnating lamination machine Applicable adhesives

Kuntai Group

Resin, fire retardant chemical, etc.

AccessoriesOption

01020304050607080910

automatic impregnating lamination Machine Features

Kuntai Group

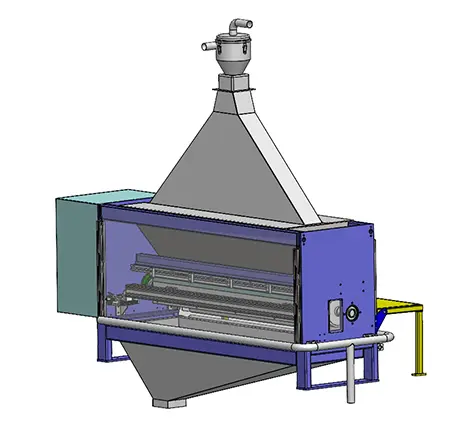

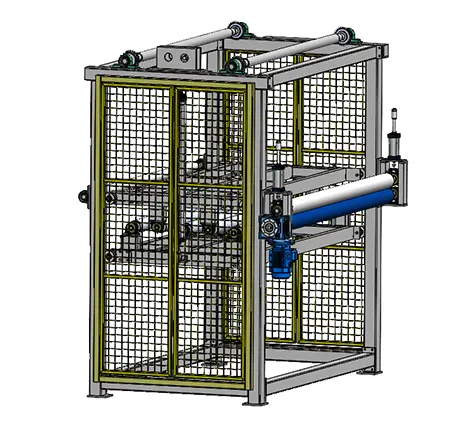

1. The non-weft fabric production line adopts stable mechanical operation rollers and special-shaped devices to spread the fibre evenly, impregnate with resin glue and lamination with the carrier PE film, dry and solidify, and then go through the 0/90º orthogonal lamination in the back. The product has excellent properties such as low density, abrasion resistance, impact resistance, and strong cutting resistance.

2. The equipment uses resin adhesives to produce non-weft fabrics.

3. Adopt HMI+PLC control system, easy operation, high production efficiency, and reduce the tedious operation.

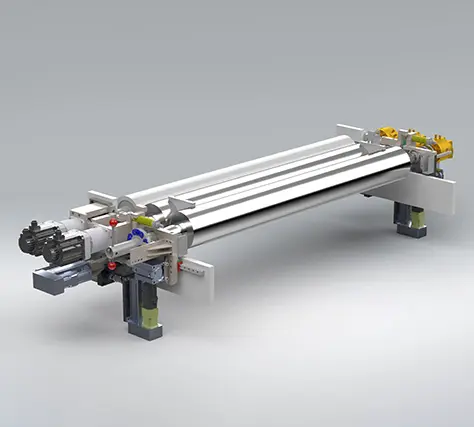

4. The mirror surface processing rollers are used for fibre pulling and fibre laying to ensure that the damage to the fiber performance is reduced to the greatest extent during the operation.

5. The machine adopts gear transmission, which has strong torque transmission and stability.

impregnating lamination machine Technical Parameters (Customizable)

Kuntai Group

| Machine roller width | 1800mm |

| Max material width | 1650mm |

| Gluing method | Dipping glue |

| Spreading method | Mechanical multi-roller+special shaped |

| Control mode | HMI+PLC |

| Drive control | Variable frequency drive |

| Heat source mode | Oil heater |

| Temperature control method | Module |

| Roller surface treatment | Mirror surface of the friction roller of the whole machine |

| Dynamic balance | Mirror roller heating roller of the whole machine |

| Total power | 90kw |

| Lamination speed | 5-11m/min |

| PLC Brand | Mitsubishi |

| Main Motor Brand | Siemens |

| Inverter Brand | Yaskawa |

| Electrical Parts Brand | Schneider/Omron |

| Temperature Control Brand | Fuji |

automatic impregnating lamination machine Application

Kuntai Group

automatic impregnating lamination machine Packaging And Shipping

Kuntai Group

Inner Package: Protective Film, etc .

Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88