2025-07-19

When choosing Laminating Machine for waterproof jacket, one important factor is to use the least possible glue for laminating, so that the final jacket can be as light as possible. For this point, people find out when applying glue onto film and then laminate with fabric, it takes much less glue than applying glue onto fabric and then laminate with film. Because of less glue, the final jacket is light and soft.

Apart from glue quantity, which type of glue to be used for laminating jacket is also one of the influential factors. Initially, people use solvent based glue/PU glue which has strong bonding capacity for laminating film with fabric, while slowly slowly solvent based glue/PU glue is replaced by hot melt PUR glue, because hot melt PUR glue is healthy and environmentlly friendly and its bonding strength is same as solvent based glue/PU glue.

Because there are many types of fabrics used in laminating waterproof jacekt, there are a variety of laminating machines catering to different fabric features. Sometimes, laminating machine structure can be different because of different area workers have different operating habits.

How is waterproof jacket fabric laminated?

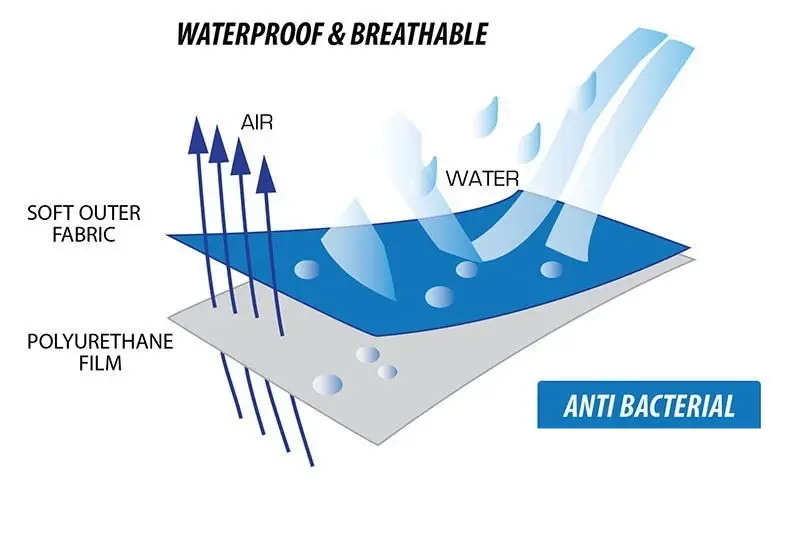

The fabric of the waterproof jacket mainly consists of two types: (1) One type is the microporous film laminating. In China, the most common brands are GORE-TEX, DENTIK, EVENT, and 3TO1-TEX. Its waterproof and breathable function is achieved by lamnating a microporous film on the outer layer of the fabric by laminating machine. The micropores in this film are smaller than water droplet molecules but larger than gas molecules, which can prevent rain while allowing the body's sweat to evaporate. (2) The other type is the hydrophilic fabric coated with PU or TPU (or with a coating). Its function is achieved through an unporous waterproof layer and a hydrophilic molecular chain structure. Today, we will talk about waterproof jacket laminating technology. Waterproof jacket laminated fabrics: 1. Two-layer laminated fabric - Only one layer of waterproof breathable membrane is laminated on the outer fabric by laminating machine. When making the garment, an additional layer of lining needs to be added inside to protect the waterproof breathable membrane layer. 2. Three-layer laminated fabric - The waterproof breathable membrane is laminated on the outer fabric, and then another layer of lining is laminated by the same laminating machine. When making the garment, no additional lining is required. 3. Two-and-a-half-layer fabric - The waterproof breathable membrane is laminated on the outer fabric by laminating machine, and then a protective layer (not lining) is laminated. When making the garment, since there is already a protective layer, no additional lining is needed, but it is much thinner and softer than the three-layer laminated fabric.

Wechat: ANNIELV88

Wechat: ANNIELV88