In the dynamic landscape of manufacturing, the integration of Thermohydraulic Coating Automatic Cutting technology represents a significant leap towards enhanced operational efficiency. According to recent industry reports, the global market for automatic cutting technologies is projected to reach USD 2.5 billion by 2025, driven by the need for precision and reduced production times. This innovative approach not only streamlines the cutting process but also improves material utilization, with studies indicating a potential waste reduction of up to 30%. By harnessing the power of thermohydraulic coatings, manufacturers can achieve superior surface finishes and increased durability of cut components. As industries continue to embrace automation, the future of Thermohydraulic Coating Automatic Cutting promises to reshape production dynamics, ultimately leading to greater profitability and sustainability.

Thermohydraulic coating is a cutting-edge technology that combines thermal and hydraulic processes to create durable coatings on various industrial materials. This technique involves applying heat and pressure to achieve a robust bond between the coating and the substrate, significantly enhancing the material's resistance to wear, corrosion, and thermal stress. Industries such as aerospace, automotive, and manufacturing benefit immensely from these coatings, as they prolong the lifespan of components and improve operational efficiency.

The applications of thermohydraulic coatings are vast. In aerospace, for example, components are often exposed to extreme temperatures and corrosive environments, making effective coatings essential for safety and performance. In the automotive sector, these coatings enhance engine efficiency by reducing friction and heat loss. Additionally, manufacturing machinery experiences less downtime due to fewer failures related to coating degradation, ultimately leading to increased productivity. As technology evolves, thermohydraulic coatings are poised to play a crucial role in developing more sustainable and efficient industrial processes.

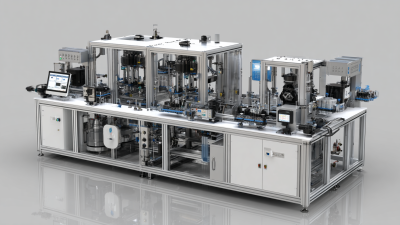

Automatic cutting technology has revolutionized manufacturing processes by enhancing efficiency and precision. This technology employs automated systems to execute cutting tasks with minimal human intervention, allowing manufacturers to streamline their operations. Unlike traditional cutting methods, which often rely on manual labor and can lead to inconsistencies, automatic cutting utilizes advanced machinery programmed to deliver consistent results every time. This not only reduces wastage of materials but also ensures that products meet strict quality standards.

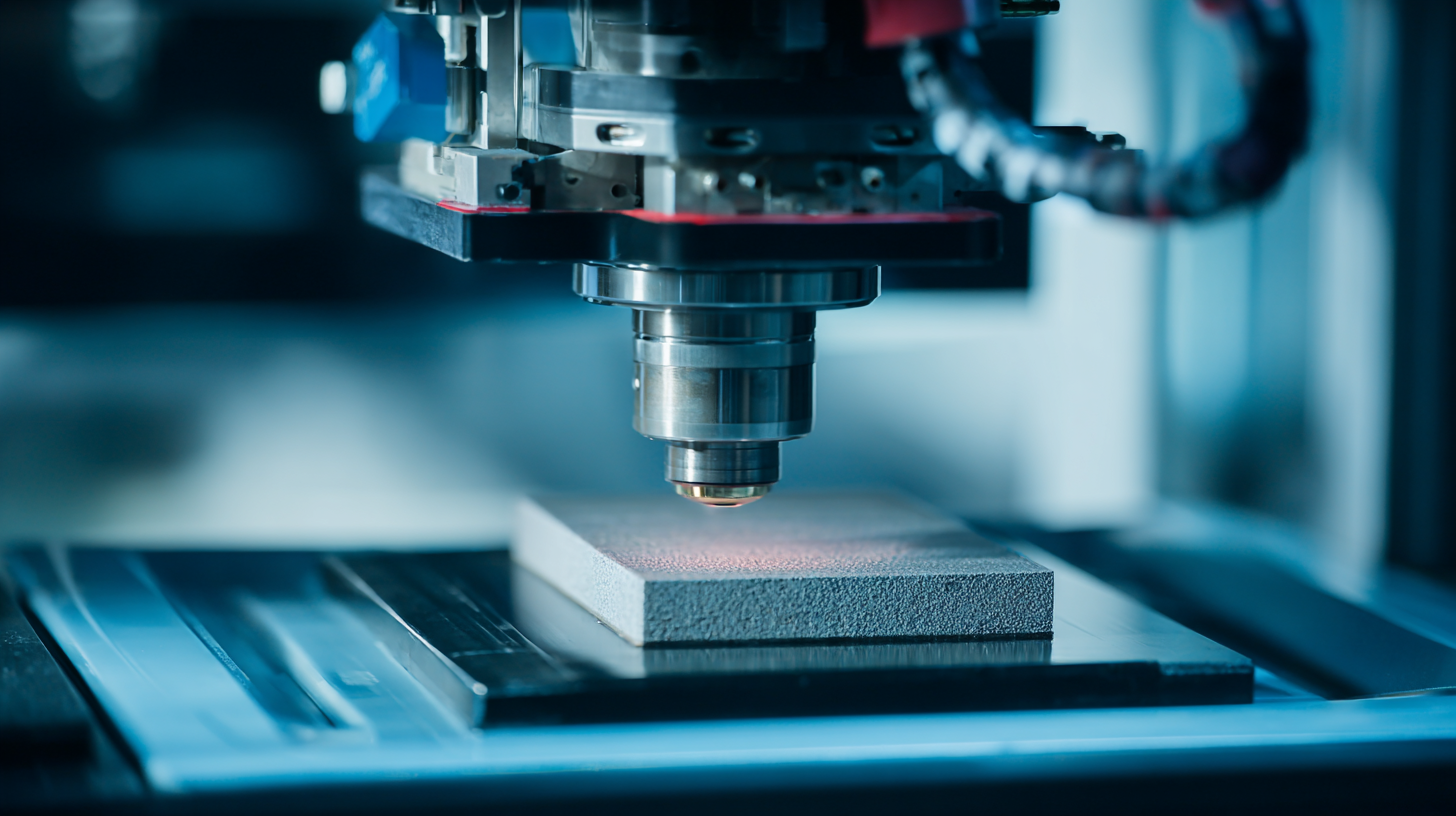

In the context of thermohydraulic coating, automatic cutting technology plays a crucial role. It enables manufacturers to precisely cut coated materials, ensuring that the properties of the coating are preserved while achieving accurate dimensions. The integration of sensors and smart technology allows for real-time adjustments during the cutting process, further enhancing the quality and efficiency of production. As industries continue to evolve, the application of automatic cutting systems is expected to expand, setting new benchmarks for precision and productivity in manufacturing.

This chart illustrates the efficiency improvements of automatic cutting technology in manufacturing over the past five years. Significant advancements have been made in reducing cycle times and increasing output quality, showcasing the potential future of thermohydraulic coating applications.

The integration of thermohydraulic coating with cutting techniques presents numerous advantages that can significantly enhance manufacturing processes. By utilizing this technology, industries can achieve superior surface quality and durability in their products. Thermohydraulic coatings create a protective layer that minimizes wear and tear during cutting operations, ultimately extending the life of cutting tools and reducing maintenance costs. This synergy not only boosts productivity but also ensures that components meet stringent quality standards.

**Tips:** When considering the implementation of thermohydraulic coatings, it's essential to evaluate the specific needs of your production processes. Conducting a thorough analysis of material compatibility and coating thickness can lead to optimal outcomes. Additionally, training your team on the latest cutting techniques will maximize the benefits of this technology integration.

Moreover, the compatibility of thermohydraulic coatings with various cutting methods allows for versatility across different applications. Whether in aerospace, automotive, or manufacturing sectors, this technology can streamline operations, reduce energy consumption, and lower waste. By embracing these advancements, companies can position themselves at the forefront of innovation, leveraging cutting-edge solutions to maintain a competitive edge.

**Tips:** To further enhance efficiency, consider implementing predictive maintenance strategies that align with the advanced capabilities of thermohydraulic coatings. This proactive approach can help identify any potential issues before they escalate, ensuring continuous optimal performance.

The implementation of automated cutting systems for thermohydraulic coatings requires a systematic approach to maximize efficiency and precision. The first step involves assessing the specific requirements of the production line, including material types, thicknesses, and desired cutting accuracy. Detailed analysis helps in selecting the appropriate cutting technology, whether laser, waterjet, or plasma cutting, each offering unique benefits for different coatings and application needs.

Next, integrating automated cutting technology into existing operations necessitates robust planning. This includes ensuring compatibility with other production equipment and securing software that can handle real-time adjustments based on the material properties. Training staff to operate and maintain these automated systems is crucial; they must understand both the cutting technology and the software to troubleshoot and optimize performance. A gradual rollout of the system, perhaps through pilot projects, can help identify any potential issues and allow operators to become accustomed to the new equipment without overwhelming the production flow.

| Process Stage | Technology Used | Efficiency Rate (%) | Cost Savings ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Material Preparation | Laser Cutting | 90 | 5000 | 4 |

| Coating Application | Spray Coating | 85 | 7000 | 6 |

| Quality Control | Automated Inspection | 92 | 3000 | 2 |

| Packaging | Robotic Packing | 88 | 4000 | 3 |

| Waste Management | Smart Recycling | 80 | 2000 | 3 |

The future of thermohydraulic coating and cutting technology is poised to undergo significant innovations driven by advancements in materials science and automation. As industries strive for greater efficiency and sustainability, emerging techniques are expected to enhance the performance and ease of application of thermohydraulic coatings. This shift is not just about improving product quality, but also about reducing environmental impacts through the use of safer, non-toxic materials. Recent developments in fabric innovations suggest a parallel advance, as researchers focus on creating high-performance coatings that minimize harmful substance usage, reflecting the increasing regulatory pressures and consumer demand for greener options.

Moreover, as technological trends evolve, the incorporation of intelligent automation in cutting processes will redefine production capabilities. The flexibility and precision offered by automated cutting technology are becoming crucial, particularly in highly competitive markets. With the anticipated growth in the chemical industry and the rise of alternative battery technologies, maintaining a focus on innovation will be essential. The integration of thermohydraulic coatings with advanced cutting technologies could further streamline operations, reduce waste, and set new benchmarks for industry standards as we advance towards 2026 and beyond.